A method for preparing anthraquinone by anthracene oxidation using a starch-modified catalyst

A starch modification and catalyst technology, applied in the chemical industry, can solve the problems of unfavorable industrialization, strong oxidizing and strong corrosive equipment damage, etc., and achieve the effects of low cost, relative cost and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] 1) According to the mass ratio of starch and carrier = 1:100, take 0.05 grams of starch and 4.5-5.0 grams of γ-Al 2 o 3 , after mixing evenly, the saturated water absorption was tested to be 3.8ml;

[0062] 2) According to the mass ratio of starch and carrier = 1:100, take 0.05 grams of starch and 4.5-5.0 grams of γ-Al 2 o 3 , mix evenly, add deionized water to 3.8ml, stir evenly, impregnate at room temperature for 15 hours, put the impregnated sample in a drying oven to control the temperature at 120°C and dry for 6 hours, the process needs to be stirred 2-3 times, and then the dried Take the sample out and put it into the crucible and cover it. Set the muffle furnace roasting temperature program as room temperature → 200°C (2h) → 400°C (2h) → 600°C (2h) → 600°C (6h) → 300°C (2h) → 0°C (1h), finally take it out after cooling and grind it as a modified carrier;

[0063] 3) Preparation of starch modification catalyst:

[0064] Weigh 0.79 grams and 1.58 grams of FeN ...

experiment example

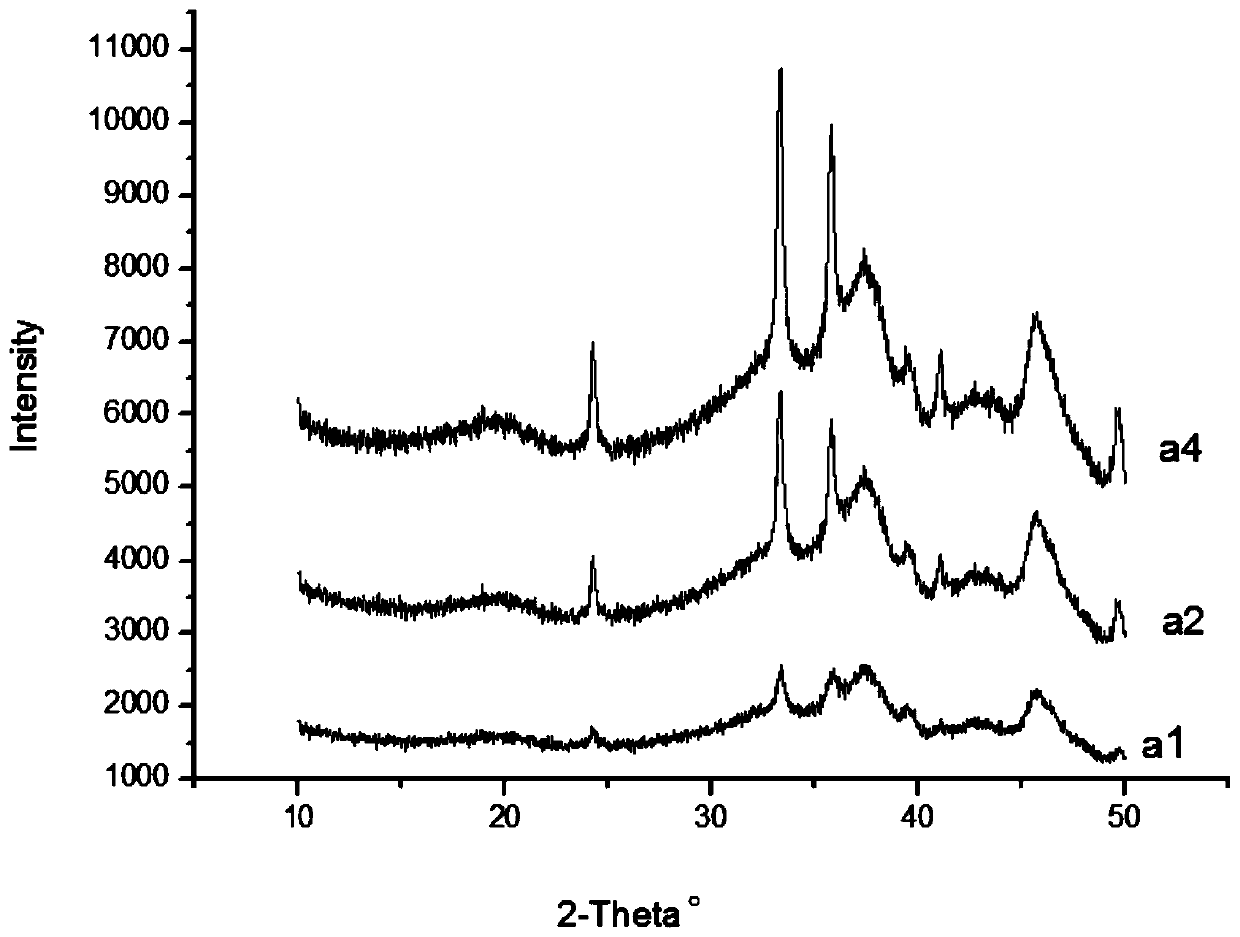

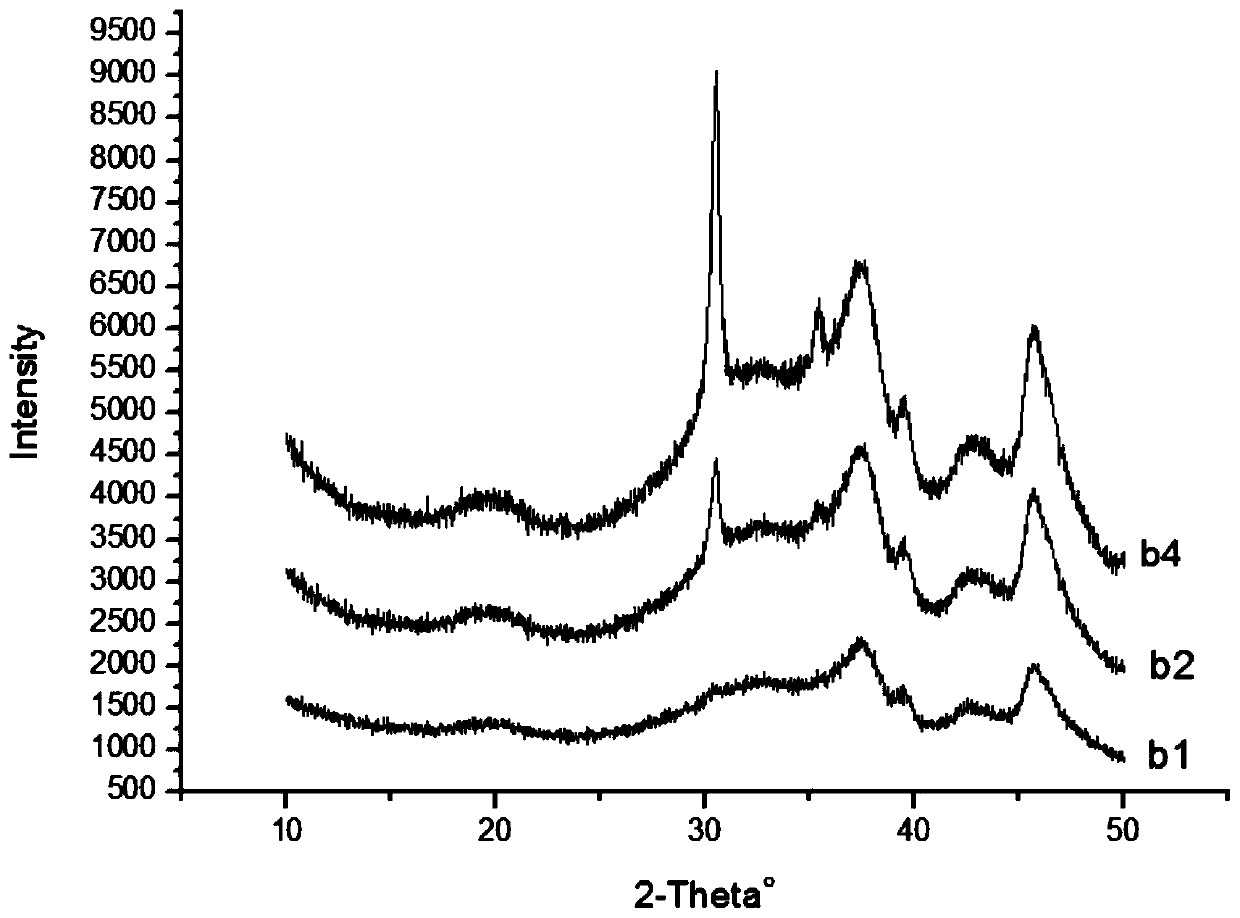

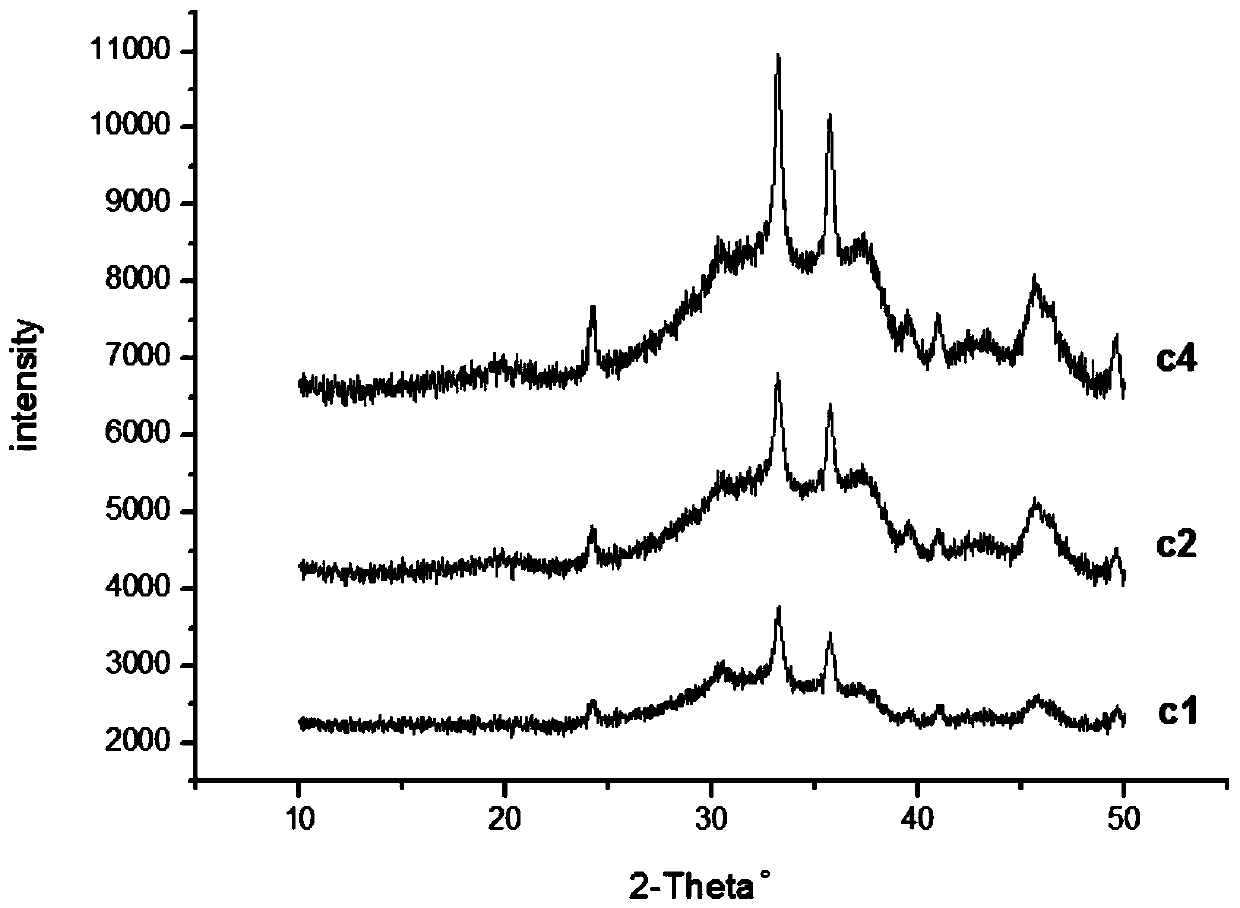

[0081] Experiment with γ-Al 2 o 3 As the carrier, Fe and Zr oxides are the active components, and the Fe-γ-Al is prepared by the equal volume impregnation method 2 o 3 , Zr-γ-Al 2 o 3 Single supported catalyst and Fe-Zr / γ-Al 2 o 3 dual-supported catalyst. Investigate the influence of the structure of catalysts with different active components on the yield of anthraquinone under normal pressure and low temperature, analyze the product by ultra-high performance liquid chromatography, and evaluate the catalytic performance of the catalyst in the reaction of anthracene oxidation to anthraquinone. XRD characterization analyzed the crystal situation in the catalyst.

[0082] Experimental Reagents and Instruments

[0083] Table 1 Main experimental reagents

[0084]

[0085]Table 2 Main Experimental Instruments

[0086]

[0087] Table 3 Distribution ratio of Fe / Al, Zr / Al single-loaded active components

[0088]

[0089] Table 4 Distribution ratio of Fe-Zr / Al double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com