Automatic welding clamp with sensing detection

An automatic welding and fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to ensure complete clamping action, inability to meet the requirements of fast and simple, low degree of automation, etc., to achieve easy and intuitive reading. The effect of short acquisition and measurement time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples cited are not intended to limit the present invention.

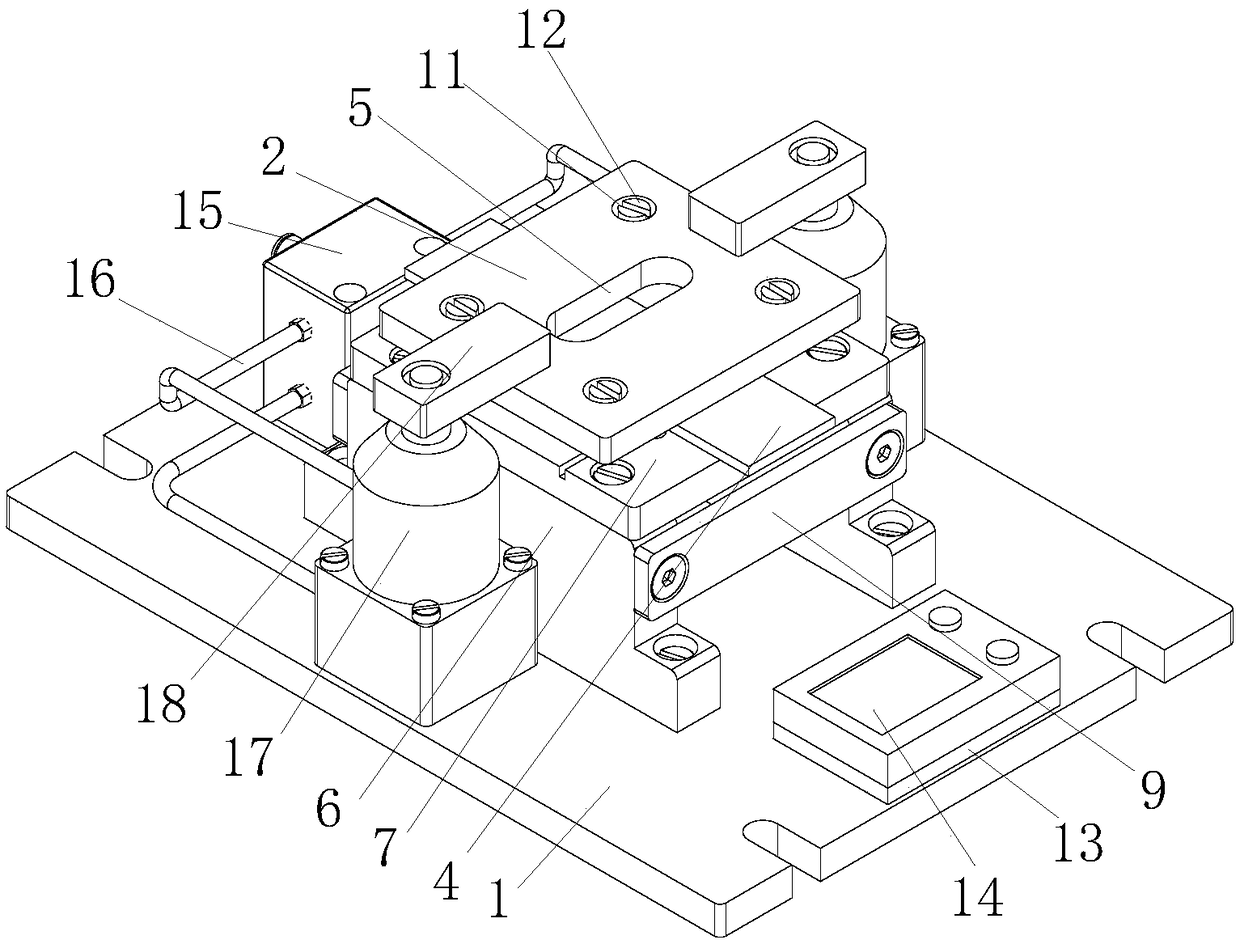

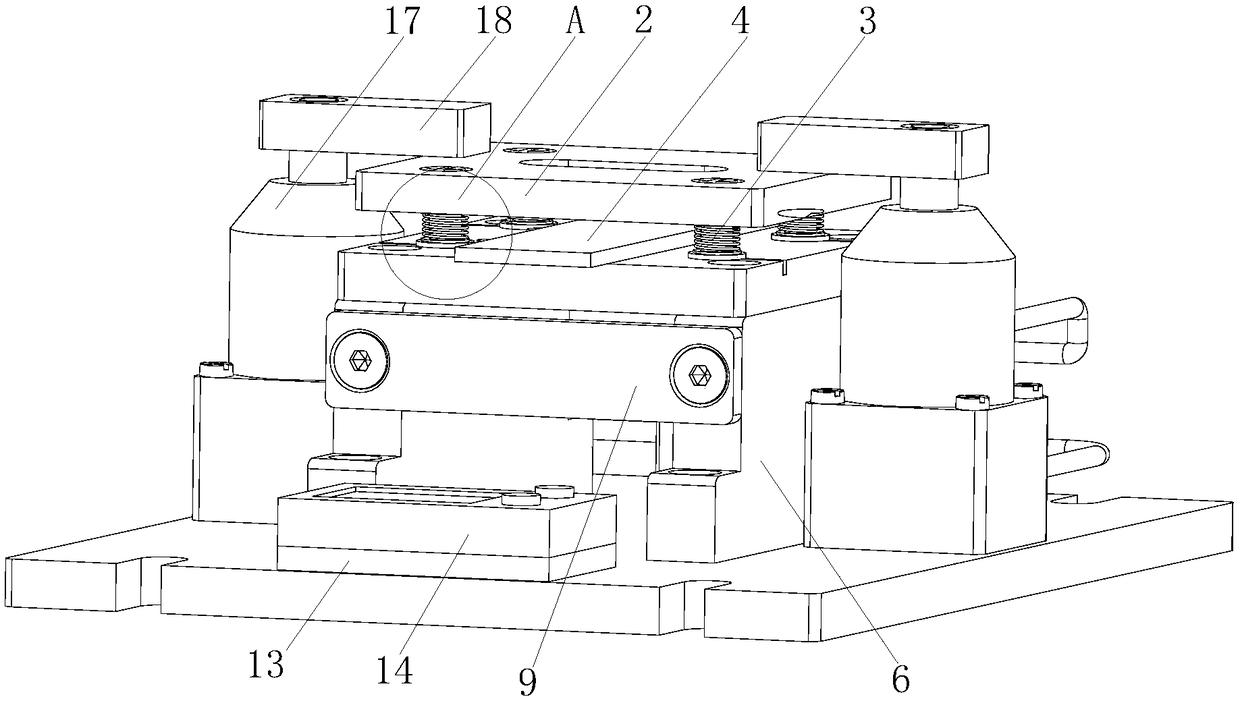

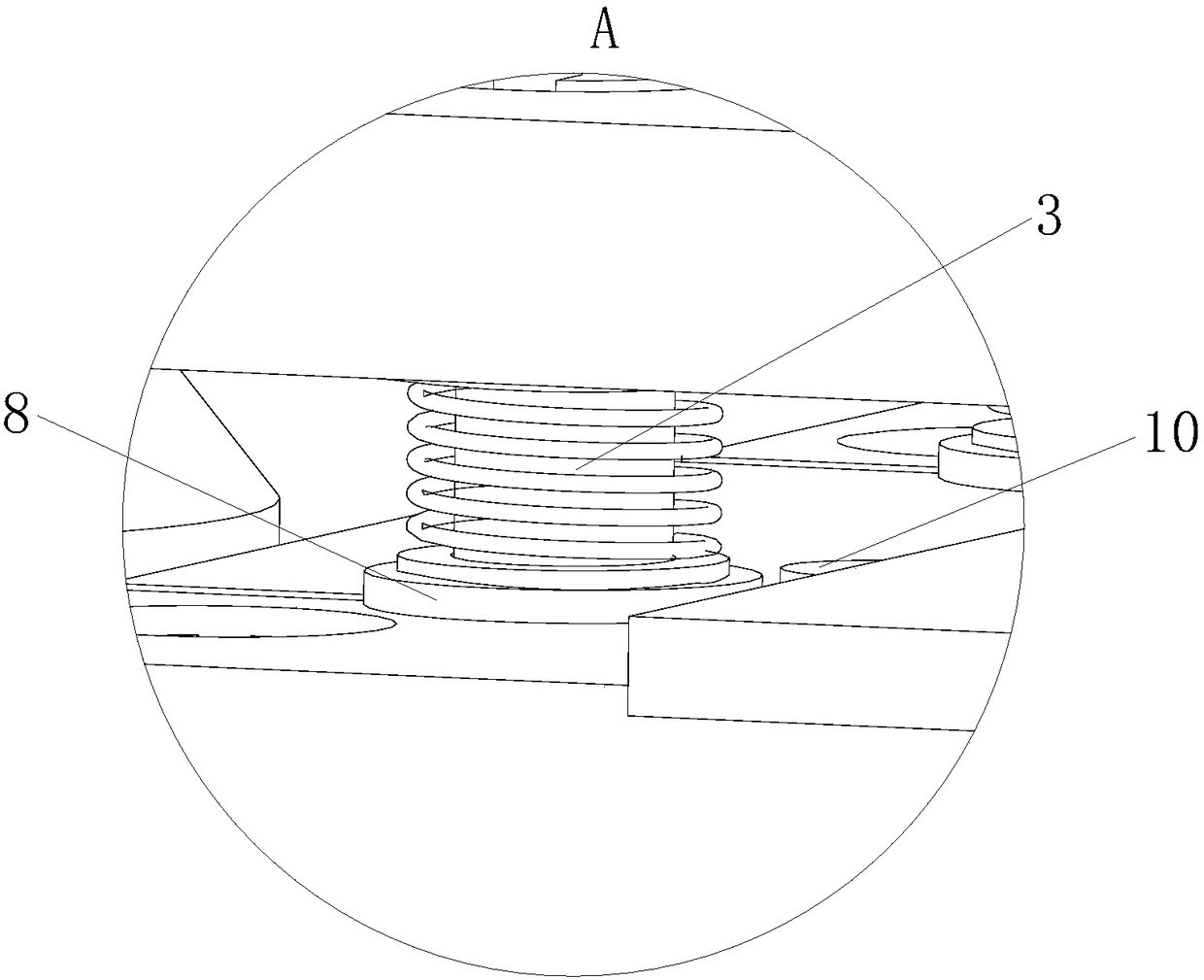

[0022] Combine figure 1 with image 3 As shown, the present invention discloses an automatic welding fixture with sensor detection, which includes a horizontally arranged bottom plate 1 on which a supporting unit for horizontally carrying the weldment 4 is provided, and is arranged above the weldment 4. The clamping unit and drive unit. The clamping unit includes a clamping plate 2 arranged horizontally relative to the bottom plate 1 and a spring 3 extending in the vertical direction. The upper end of the spring 3 abuts against the lower surface of the clamping plate 2 and the lower end abuts against the The upper surface of the support unit. In the present invention, it is preferable t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com