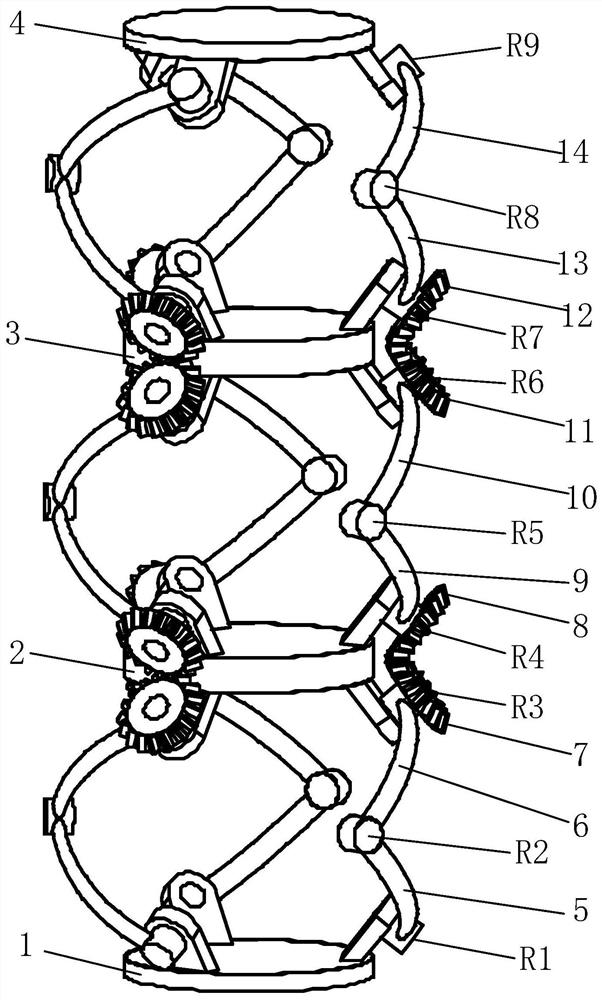

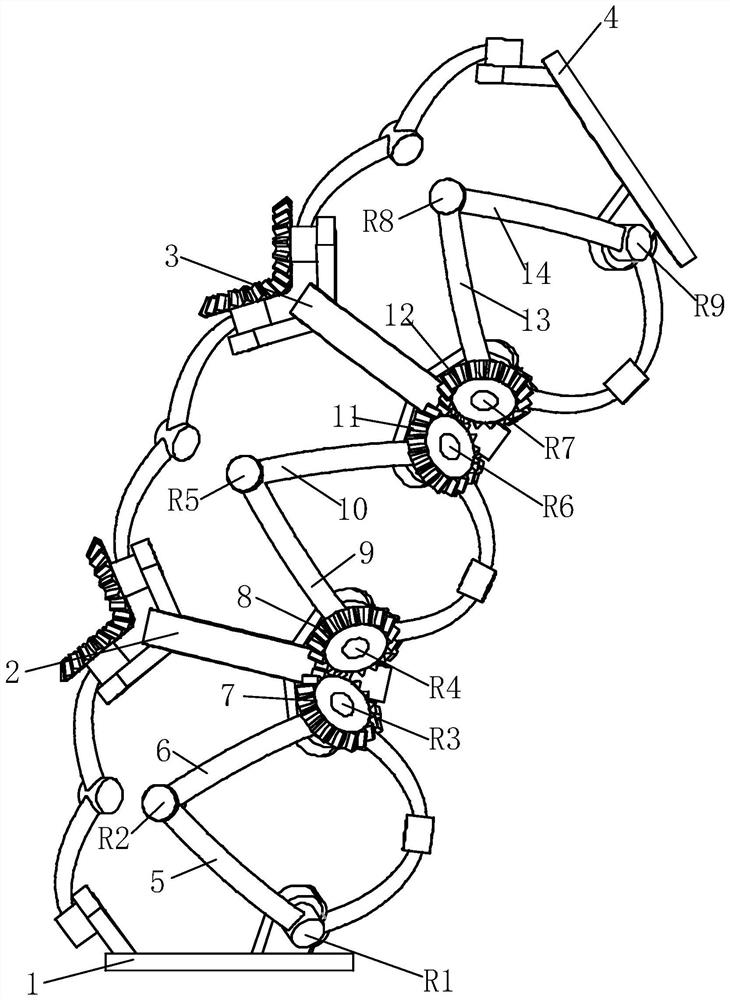

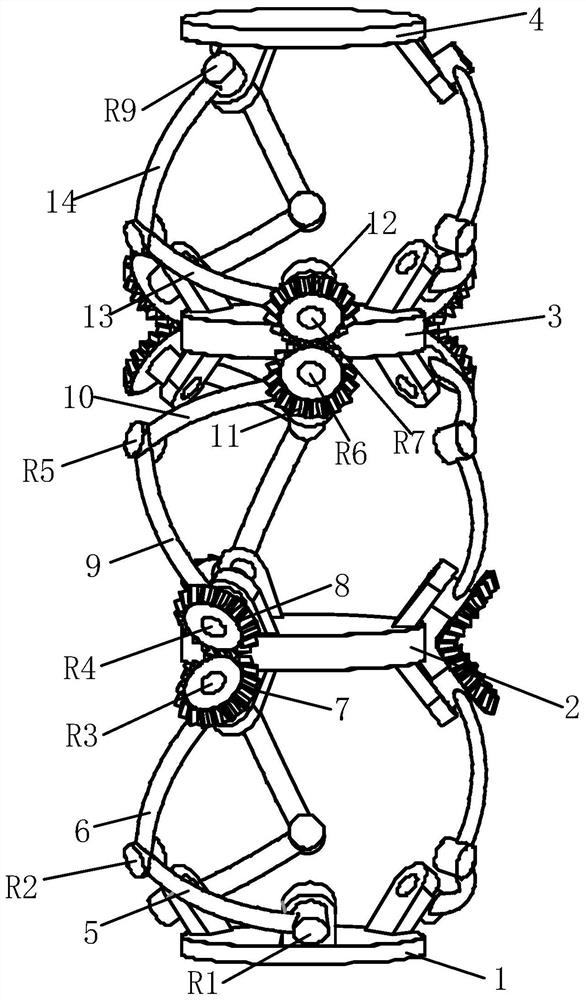

A Humanoid Robot Waist Joint Based on 3-rrr Spherical Parallel Mechanism

A humanoid robot and waist joint technology, applied in the field of robotics, can solve problems such as the low level of waist joint bionics, and achieve the effects of multiple superposition, workspace enlargement, calculation model simplification, and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] exist Figure 1 ~ Figure 4 In the schematic diagram of the humanoid robot waist joint based on the 3-RRR spherical parallel mechanism shown, it is formed by coupling three parallel mechanism units with the same structure, and the parallel mechanism unit is a parallel mechanism with three rotational degrees of freedom, which includes Fixed platform, common platform, end platform and three RRR series branch chains with the same structure and evenly distributed along the circumferential direction connecting these three platforms. Each RRR series branch chain includes a driving rod, a driven rod and a straight bevel gear, wherein One end of the active rod one 5 in the first parallel mechanism unit is connected with the fixed platform 1 through the rotating pair R1, the other end of the active rod one 5 is connected with one end of the driven rod one 6 through the rotating pair R2, and the driven rod one 6 The other end of the second parallel mechanism unit is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com