SLS rapid prototyping double-roll powder spreading device

A powder spreading device and fast technology, which is applied in the directions of additive manufacturing, processing manufacturing, solid material additive processing, etc., can solve the problem of not having powder spreading function, etc., to improve printing efficiency, facilitate powder supply, and facilitate disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

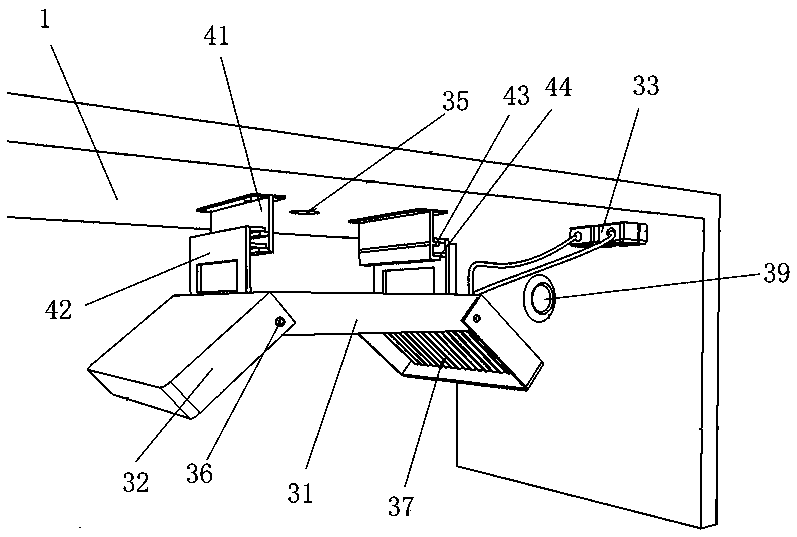

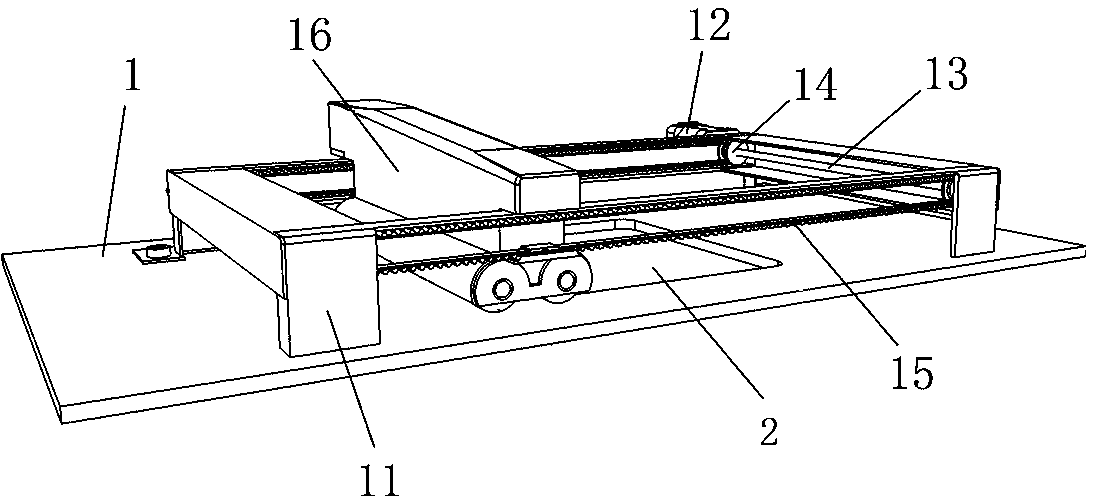

[0028] Such as figure 1 , image 3 , Figure 6 As shown, a SLS rapid prototyping double-roller powder spreading device includes a support frame 1, a mounting bracket 11 is installed on the inner bottom wall of the support frame 1, and a hopper motor 12 and a rotating shaft are respectively installed on the mounting bracket 11. 13. The motor shaft of the hopper motor 12 is connected to the rotating shaft 13, a sprocket 14 is installed on the rotating shaft 13, a chain 15 is installed on the sprocket 14, a hopper 16 is installed on the chain 15, and the hopper 16 links to each other with the powder spreading roller support 21, and the powder spreading roller motor 22, the first powder spreading roller 23 and the second powder spreading roller 24 are respectively installed on the powder spreading roller support 21, and the motor shaft of the powder spreading roller motor 22 Connect with the first powder spreading roller 23 and the second powder spreading roller 24 respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com