High temperature-resisting V-type differential steering roller

A technology of differential steering and roller sheets, which is applied in the direction of rollers, transportation and packaging, and conveyor objects, etc. It can solve problems such as steering roller stalling, steering roller bearing swelling and locking, production accidents, etc., to avoid wear and tear, Avoid uneven tightness and improve the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

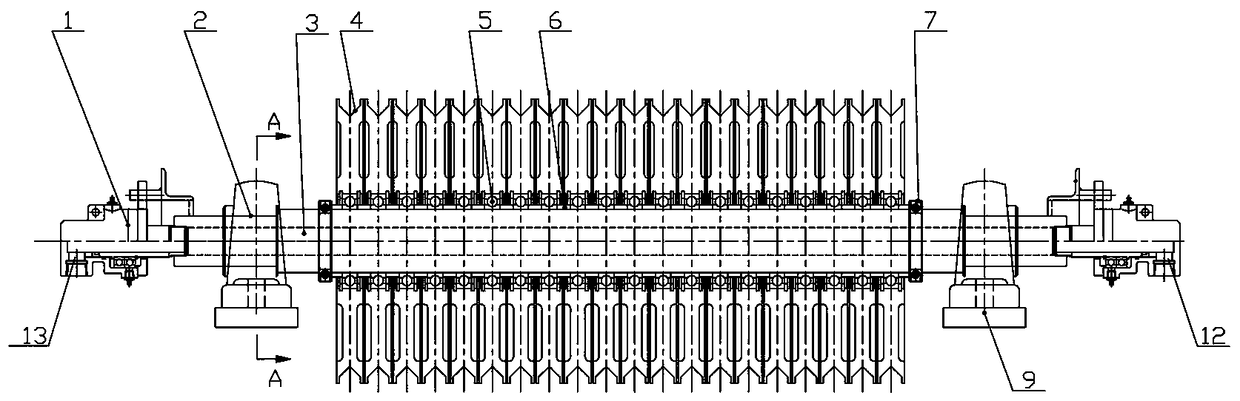

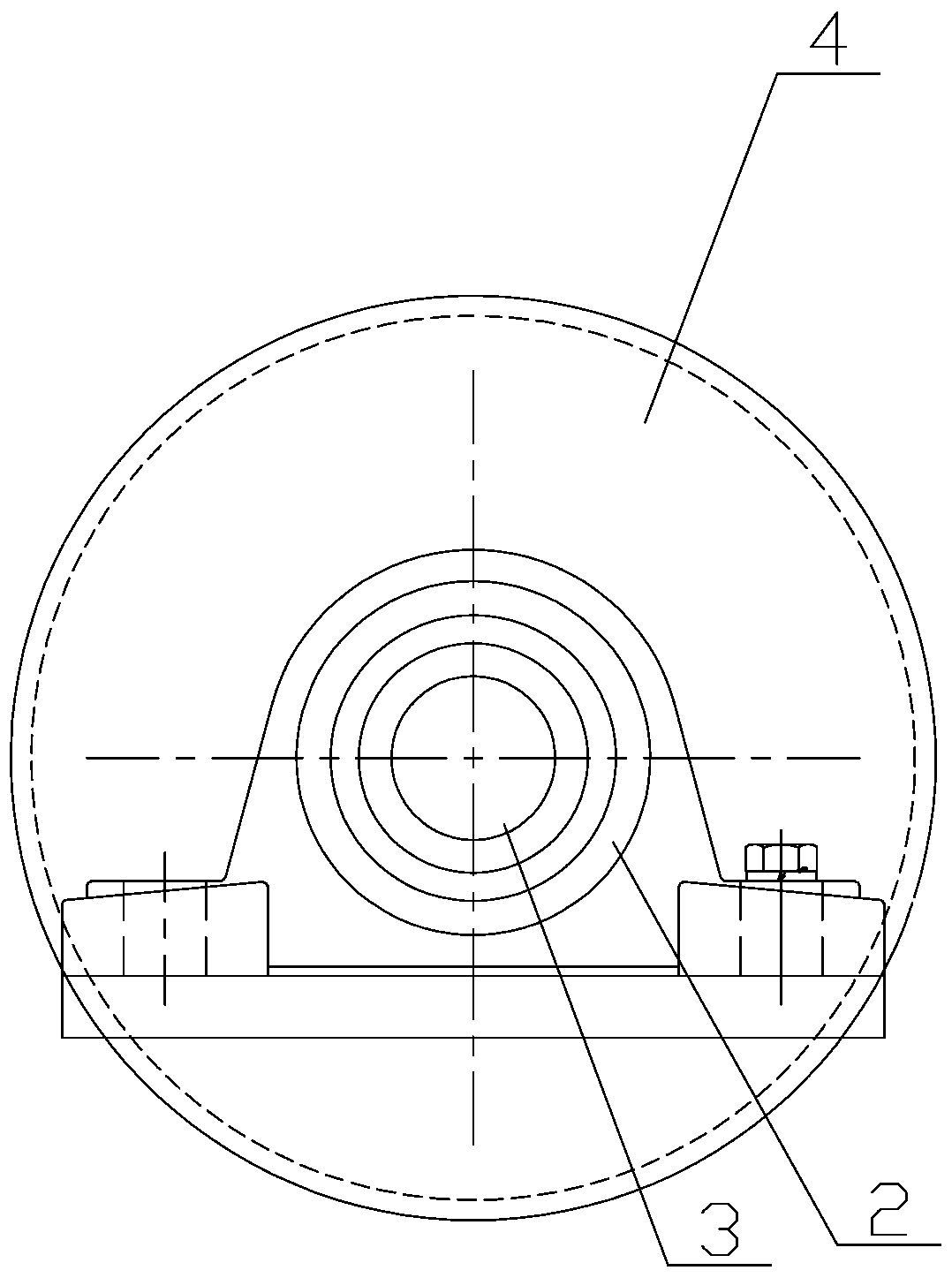

[0016] Such as Figure 1-Figure 4 As shown, a V-type differential speed diverting roll for producing a painted steel strip for packaging of the present invention includes a bearing backing plate 9 that is provided with a bearing 2 and a rotating shaft on the bearing backing plate 9, and is sleeved on the rotating shaft 3 Steering roller, retaining rings 7 arranged at both ends of the turning roller and rotary joints 1 arranged at both ends of the rotating shaft, characterized in that the rotating shaft is a hollow water-cooled shaft 3, wherein one end of the hollow water-cooled shaft 3 is provided with a water inlet 10, and the other One end is provided with a water outlet 11, and the steering roller is a V-shaped differential steering roller, and the V-shaped differential steering roller is set by a plurality of V-shaped differential steering rollers 4 set on the hollow wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com