Elevator safety system and safety control method

A safety system and electronic safety technology, applied in the field of elevator control, can solve the problems that it is not easy to detect and locate the fault position of the safety circuit, the testing process is time-consuming and laborious, and the circuit design cost is high, so as to improve the installation time and troubleshooting time, Reduce service and maintenance costs and reduce the effect of back and forth bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

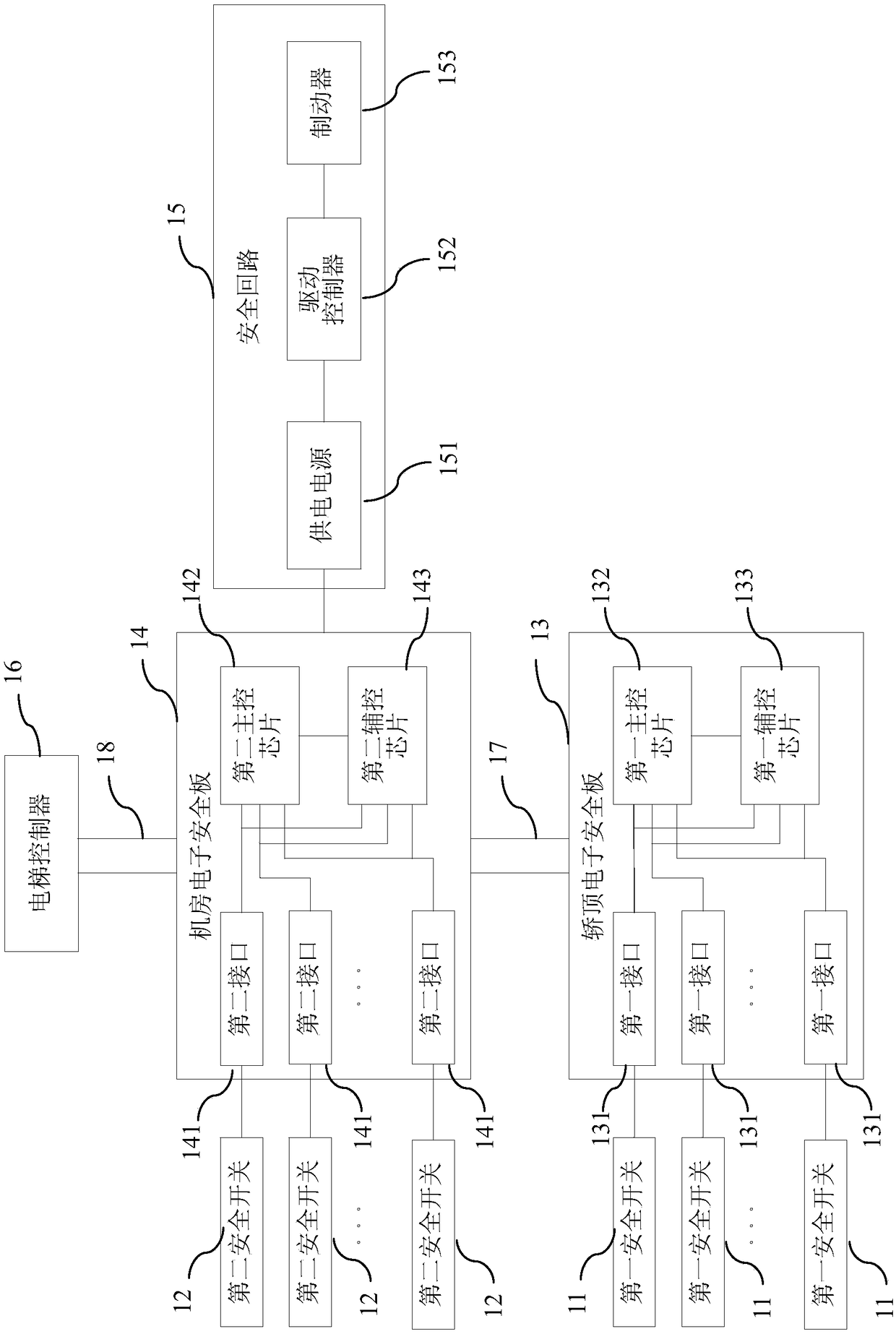

[0036] Such as figure 1 Shown is a schematic diagram of an embodiment of the elevator safety system of the present invention. The elevator safety system can be integrated into the elevator control system and combined with the existing elevator control logic to realize elevator safety operation control. In this embodiment, the elevator safety system includes a plurality of first safety switches 11, a plurality of second safety switches 12, a car top electronic safety board 13, a machine room electronic safety board 14, a safety circuit 15 and an elevator controller 16, wherein the safety The circuit 15 is formed by connecting a power supply 151 , a drive controller 152 and a brake 153 in series.

[0037] The safety circuit 15 is connected to the electronic safety board 14 in the machine room, and in the safety circuit 15, the power supply 151 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com