SO2 protective gas system with transitional roll platform in online floating-process film coating of glass and operation method

A coating glass and system operation technology, applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve problems such as pipeline blockage, affecting production stability, human hazards, etc., achieve simple process, reduce casualties and operations Process interruption, precise effect of control results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

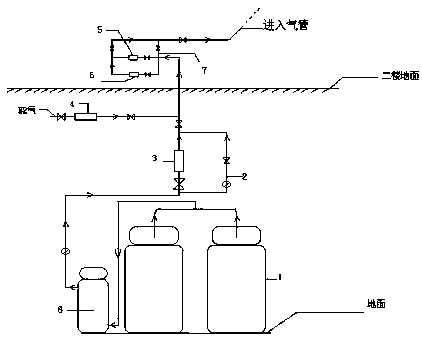

[0031] Such as figure 1 As shown, the present invention provides on-line float coating glass transition roller table SO Protective gas system, described protective gas system includes SO Gas supply system and air seal gas supply system; Wherein,

[0032] The SO2 gas supply system includes SO2 gas source, buffer tank, SO2 main pipeline rotameter, connecting pipelines and a number of manual acid-resistant stainless steel flange cut-off regulating valves, and the SO2 gas source passes through the buffer tank into the SO2 main pipeline rotor flow rate After metering, it is connected to the gas seal gas supply system pipeline through the connecting pipeline to merge with the gas seal gas, and the flow ratio of SO2 / N2 between the two is between 1 / 1-1 / 4.

[0033] The gas sealing gas supply system includes a gas source, a gas sealing gas rotameter, a rotameter required for production, connecting pipelines and a number of manual acid-resistant stainless steel flange cut-off regulating ...

Embodiment 2

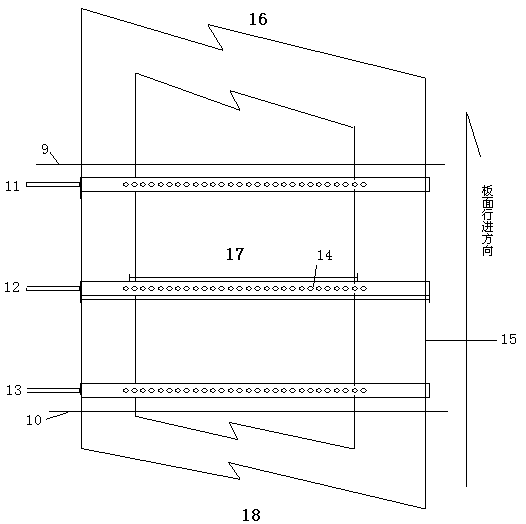

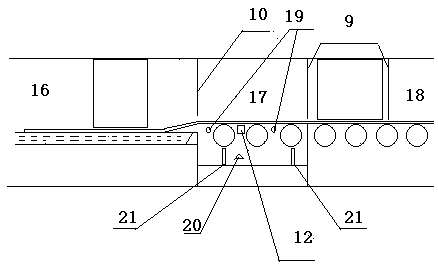

[0040] On the basis of Example 1, in order to control the flow rate, achieve less tempered iridescence, improve the surface strength of the glass, reduce the scratches on the lower layer of the glass, and delay the mold of the glass. As a preference, the SO2 trachea 7 Located at 30cm-60cm downstream of the air-sealing pipe 8 process, the SO2 air pipe 7 and air-sealing pipe 8 are arranged at 5-9cm below the glass plate surface, and the air pipe is provided with air holes 10, the diameter of which is 2-4mm. The spacing is 1-2cm, and the opening length is 3-5m. Adopting the structure of the jet tube mentioned above can also greatly reduce the impact on the coating quality. The jet tube is made of acid-resistant and high-temperature-resistant materials (below 700 degrees Celsius), which can effectively reduce the corrosion of the jet tube by SO2 gas.

Embodiment 3

[0042] As an improved form of the above-mentioned several embodiments, a SO2 gas collection device (not shown in the figure) is also provided at the position facing the SO2 gas pipe under the roller table, and the SO2 gas collection device passes through the pipeline and the suction The device is connected and passed into the lye for neutralization treatment.

[0043] It can effectively remove SO2 gas diffused in the air, and treat it with lye to reduce the pollution caused by direct emission of SO2 gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com