A stripping device for electroplating workpieces

A workpiece, stripping technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of increased workload, products cannot be automatically flushed immediately, affecting production efficiency, etc., and achieves reliable structure, good stripping effect, and less labor. The effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

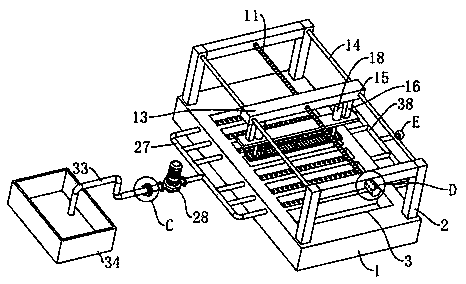

[0037] Such as Figures 1 to 7As shown, a deplating device for electroplated workpieces includes a horizontal workbench 1, a gantry 2 fixed at both ends of the horizontal workbench 1, and a water supply device.

[0038] In order to achieve good deplating, a deplating tank 3, a first washing tank 4, a second washing tank 5, a third washing tank 6, a passivation tank 7, a fourth washing tank, and a Washing tank 8, the fifth washing tank 9 and the sixth washing tank 10; when the deplating substrate is a copper workpiece and the coating contains chromium and nickel, the composition and ratio of the stripping solution in the stripping tank 3 are: stripping agent 30 %, 55% sulfuric acid, 15% water, the temperature in the stripping tank 3 is 25 to 40°C, the energizing voltage is 10 to 13V, and the deplating time is 15 to 20 minutes; when the deplating substrate is an iron workpiece, the coating When containing chromium, nickel, and copper, the composition and ratio of the stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com