Rolling isolation bearing

A technology of rolling vibration isolation and rolling shafts, which is applied in the direction of earthquake resistance, building components, construction, etc., can solve the problems of untimely recovery of displacement, side tilt, limited vertical bearing capacity of interlayer rubber pad vibration isolation bearings, etc., to improve safety Sexuality and reliability, elimination of residual deformation, reset and effect of residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a1

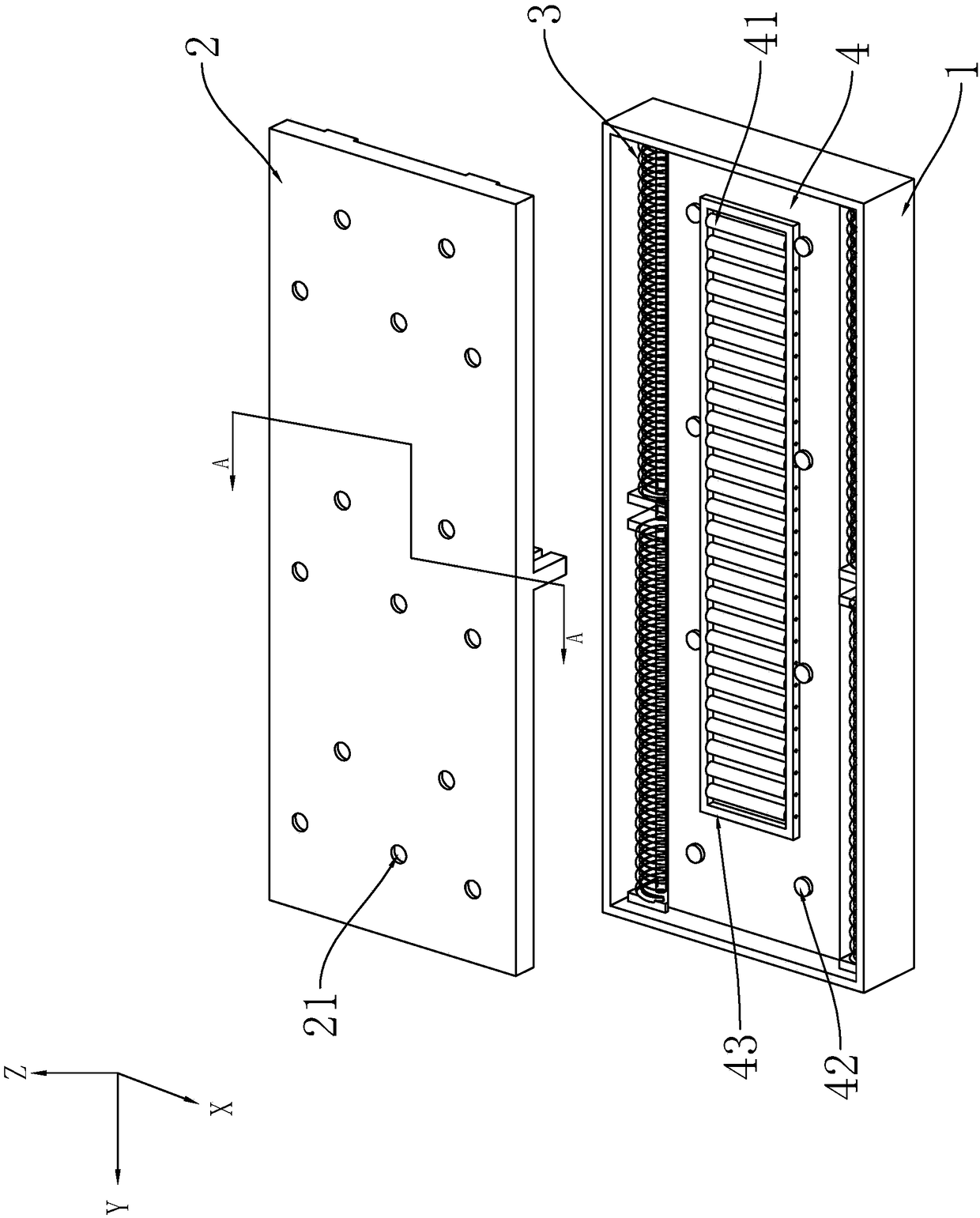

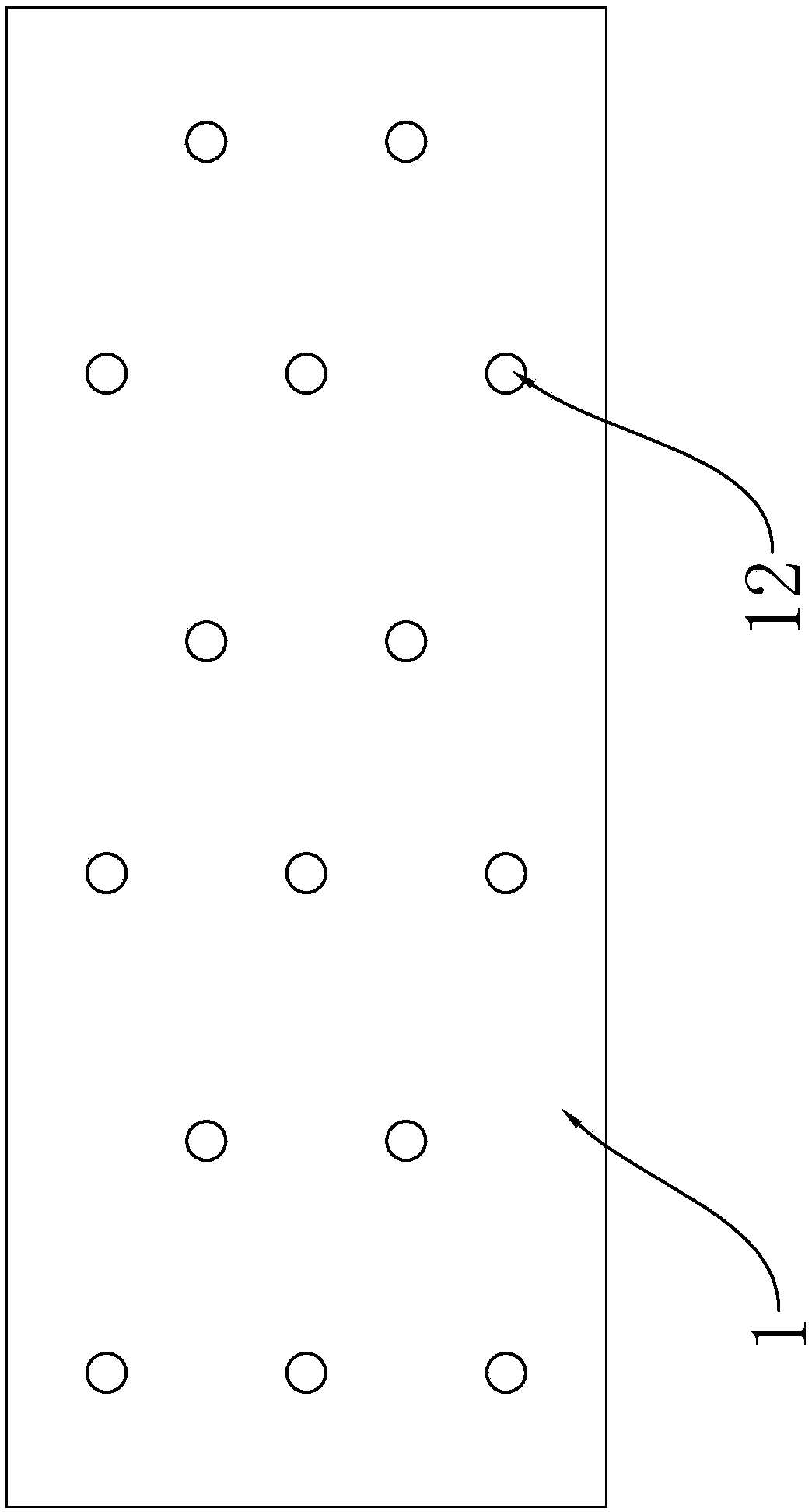

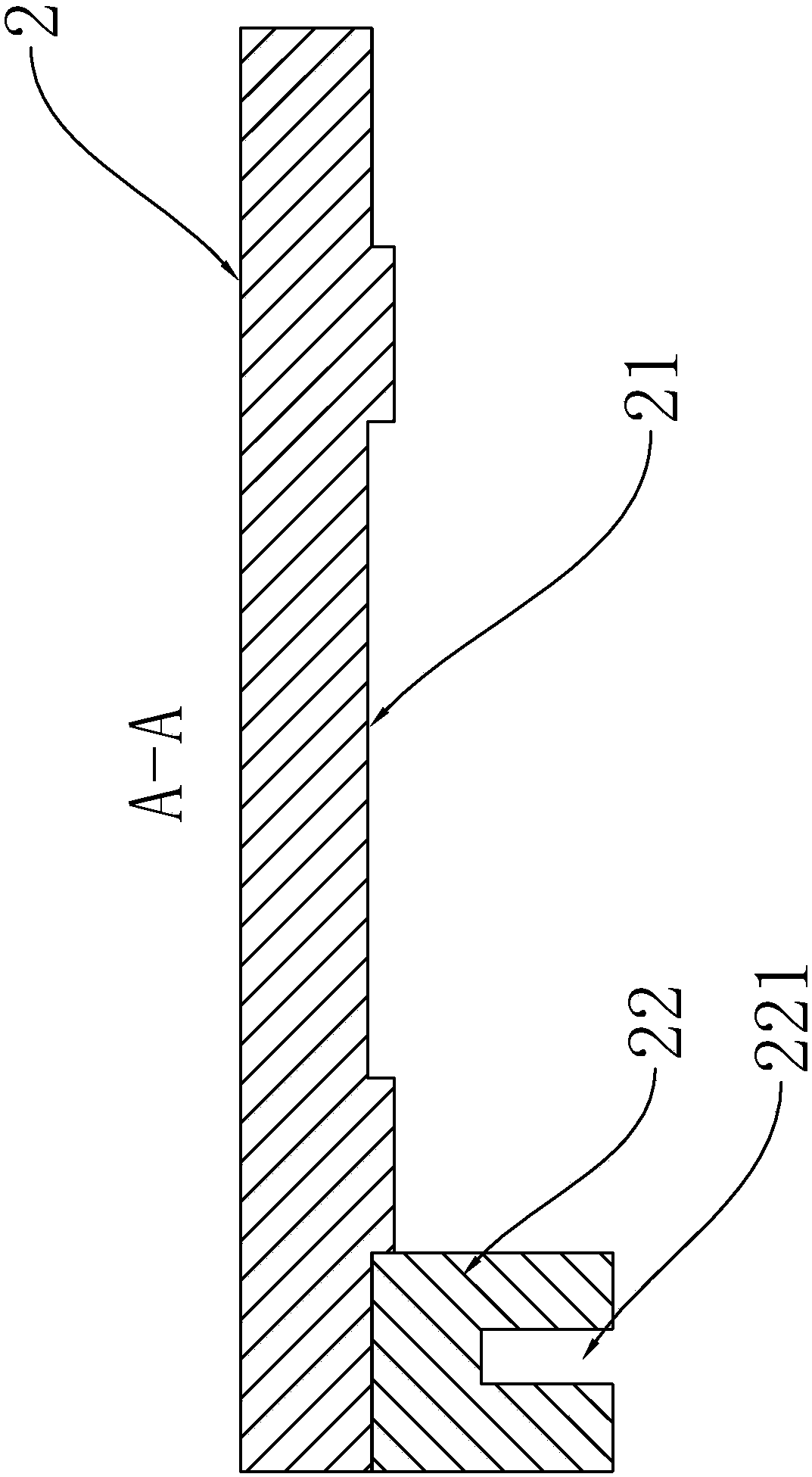

[0022] refer to Figure 1 to Figure 4 , which is embodiment a1 of the present invention, specifically:

[0023] A rolling shock-isolation bearing, comprising a rolling plate 2 and a bottom box 1, the shape of the bottom box can be other shapes such as trapezoid, rectangle or parallelogram, the present invention is preferably a rectangle, the length of the bottom box is the Y axis, the bottom box The width of the X-axis is to establish a rectangular coordinate system in space, and the rectangular coordinate system in space established is not unique, and this embodiment is only used as a preferred solution; There are two grooves parallel to the Y axis, and each groove is provided with a preloaded spring group 3, which has a preloaded elastic force when the preloaded spring group is installed on the groove. Said pre-compression spring group comprises at least two springs 31, for the consideration of cost, the present invention is preferably two springs, and the two ends of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com