Steam recovery method and system for fuel oil system, and vehicle

A fuel system and recovery method technology, which is applied to the charging system, adding non-fuel substances to fuel, engine components, etc., can solve the problems of fuel vapor leakage and high cost of high-pressure fuel tanks, reducing fuel vapor emissions and reducing matching. Work, low stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

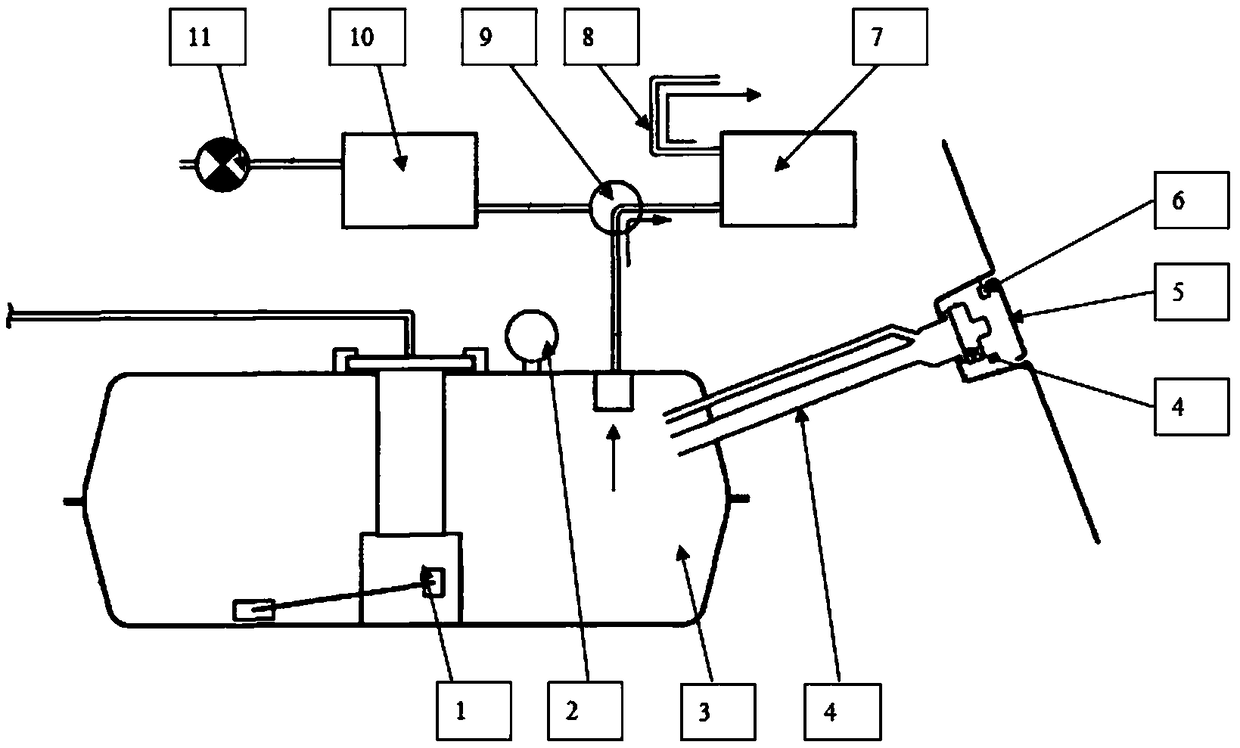

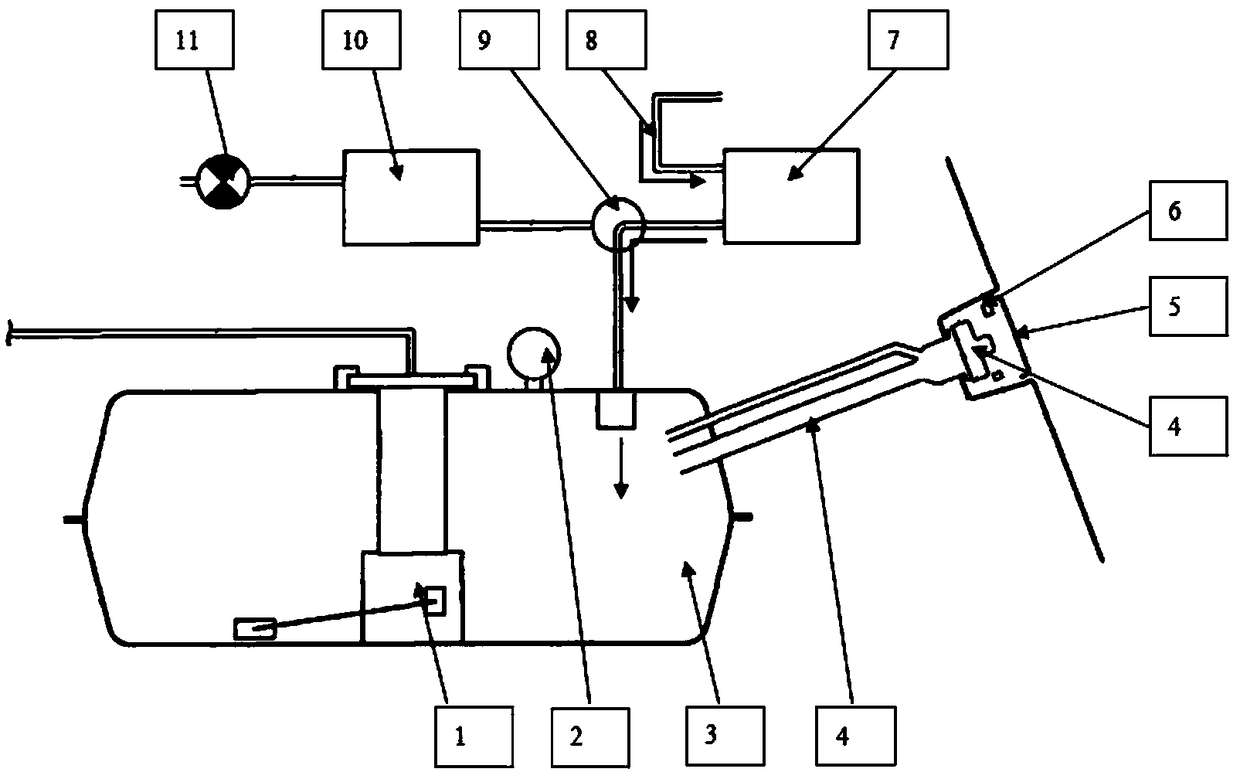

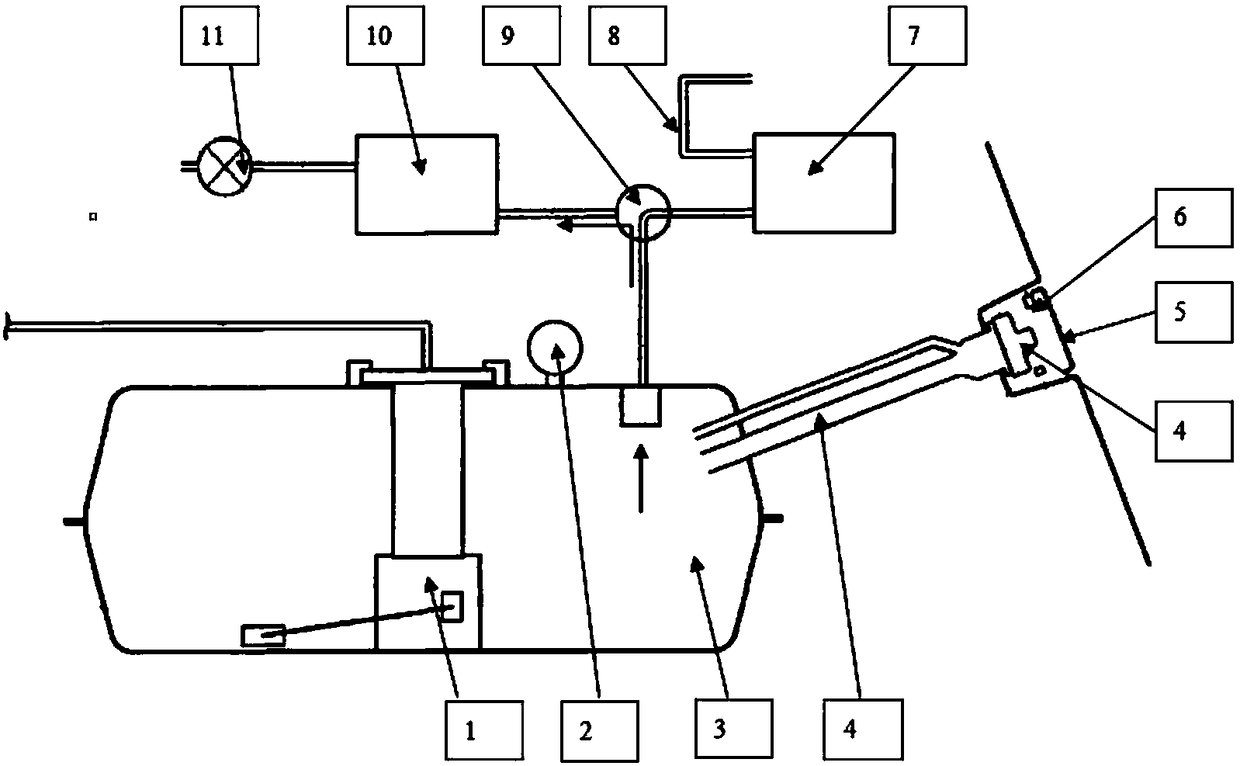

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] The vapor recovery method of the fuel system of the present invention is to absorb the oil vapor generated in the fuel system through the charcoal tank during the refueling process. During normal use, the fuel tank may generate positive pressure due to temperature rise. At this time, the oil vapor in the fuel tank passes through the oil-gas separation device to return the liquid fuel to the fuel tank, and the separated gas is discharged to the atmosphere. When the temperature drops, or the fuel in the tank decreases, a negative pressure is generated in the tank. At this time, the fuel tank absorbs fresh air through the air vent of the carbon tank, and the fresh air enters the fuel tank through the carbon tank, and at the same time desorbs the fuel vapor adsorbed in the carbon tank.

[0021] Such as figure 1 , figure 2 and image 3 As shown, the vapor reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com