Paraffin section deparaffinating device

A technology of paraffin sectioning and dewaxing, which is applied in the direction of measuring devices, sampling, instruments, etc., can solve the problems of easy fatigue and cumbersome operation, and achieve the effects of reducing workload, simplifying operation, and alleviating fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

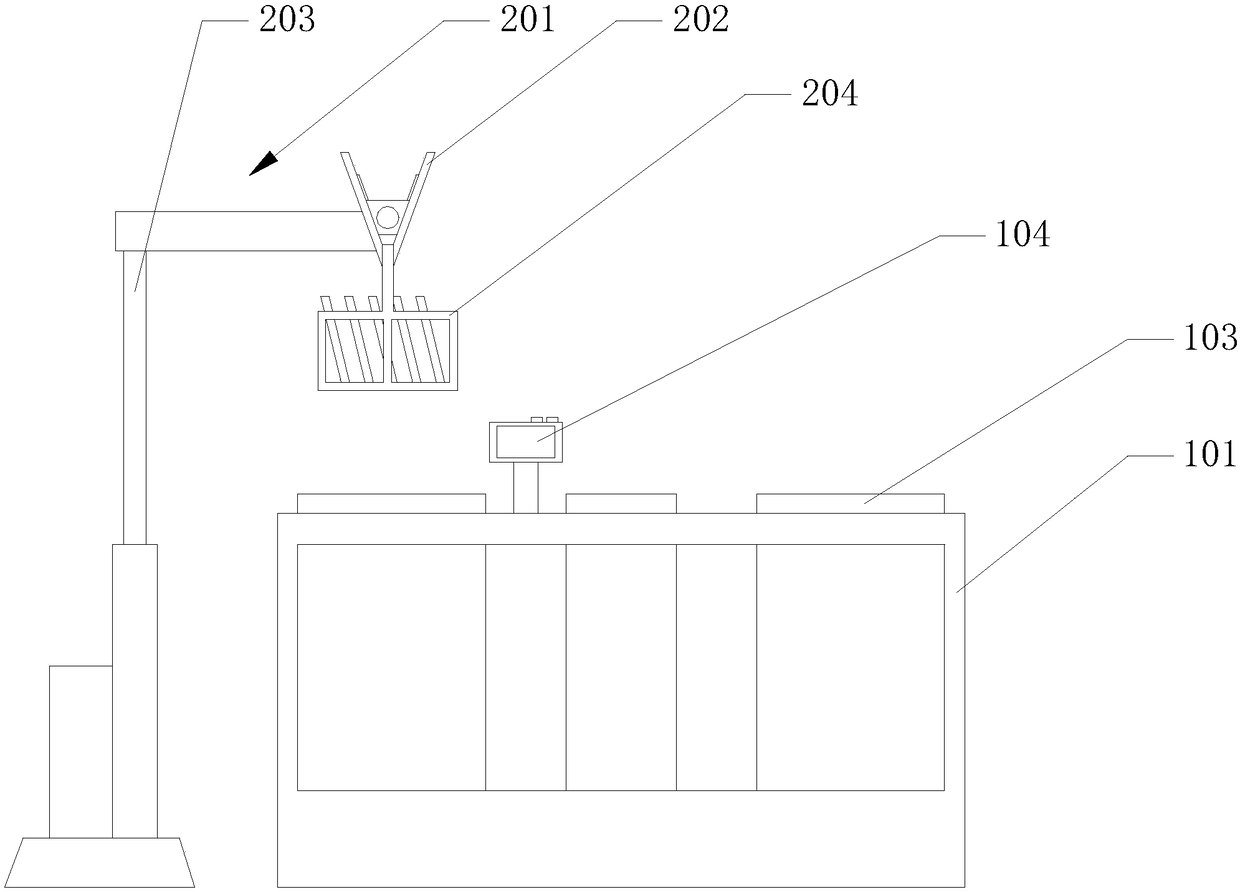

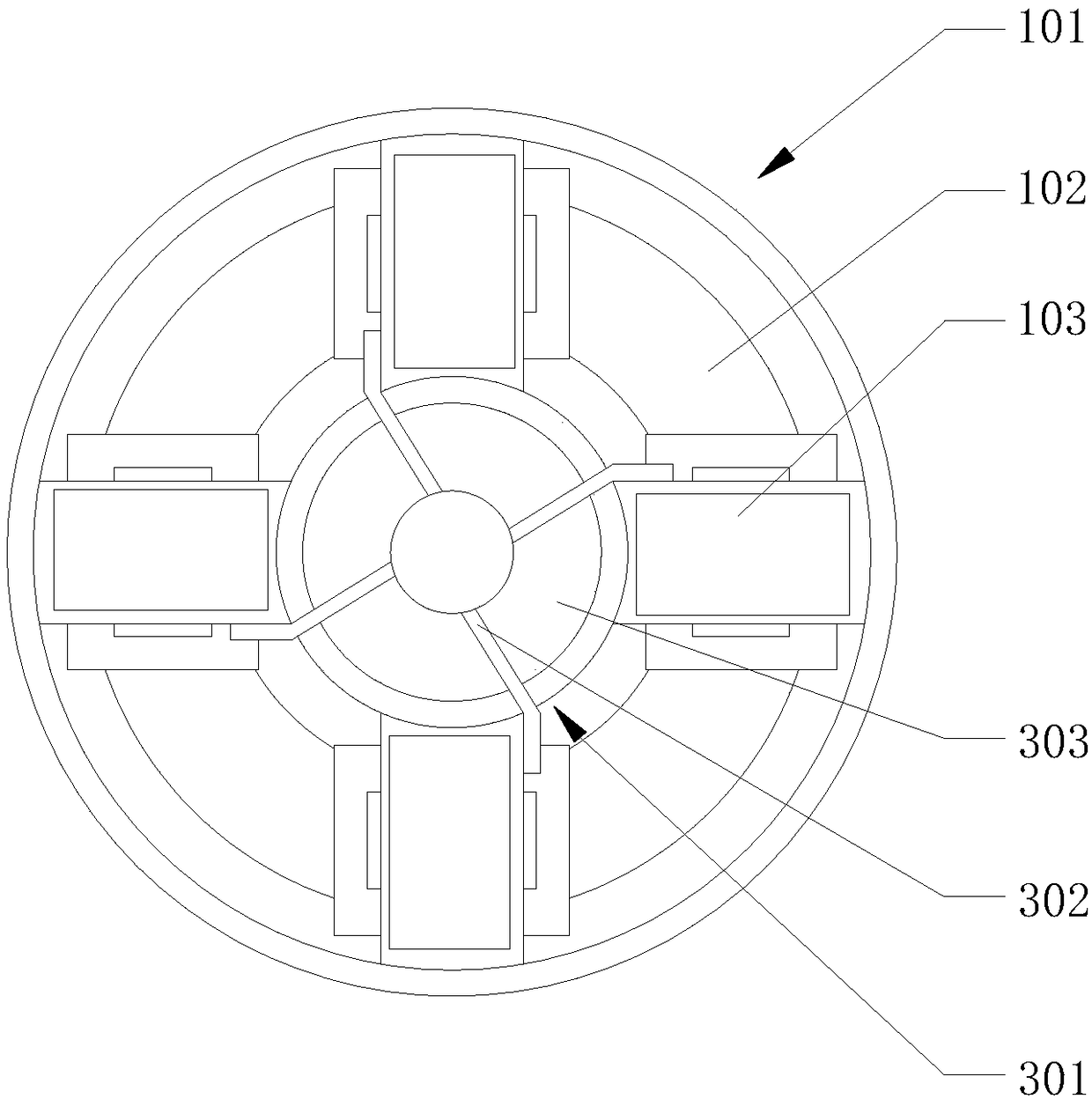

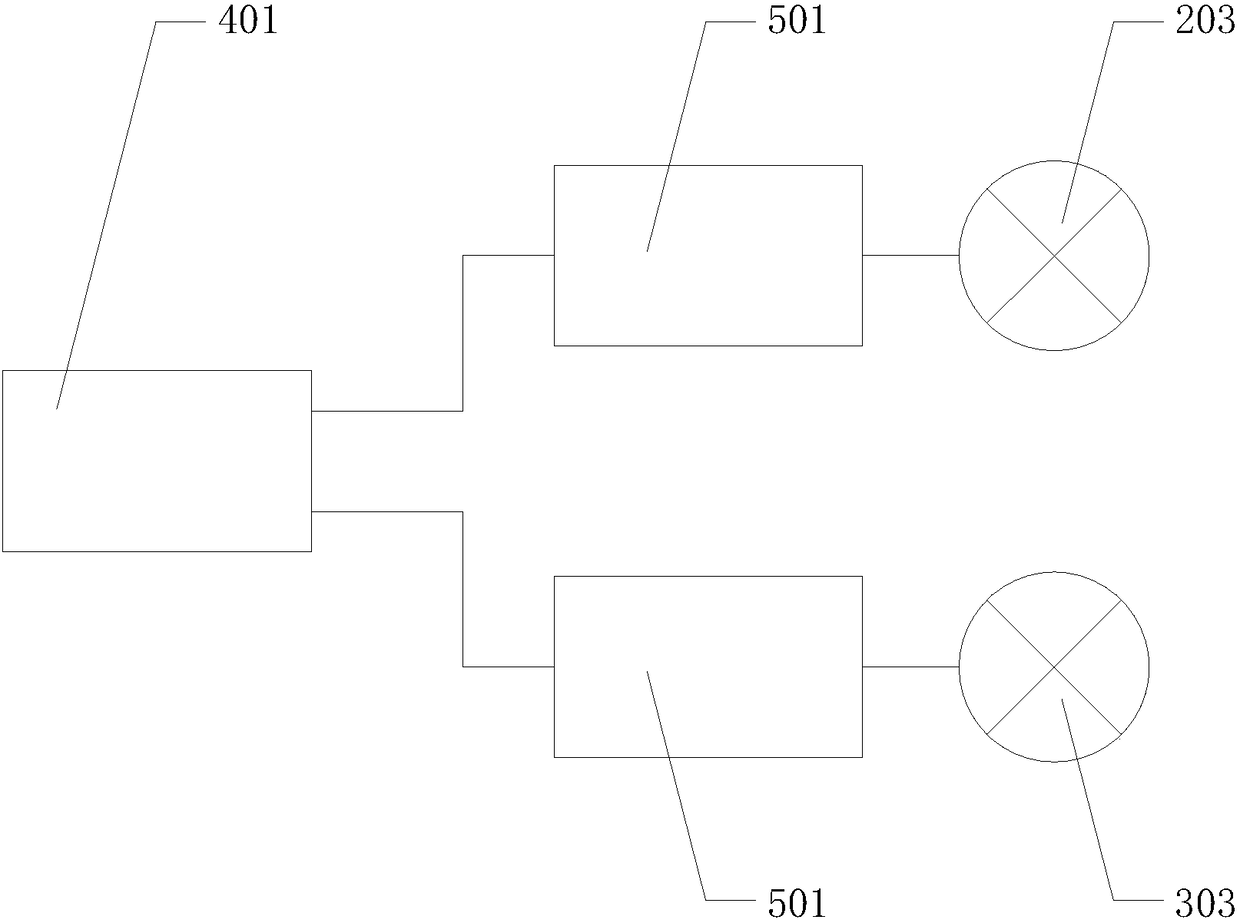

[0027] Please also refer to figure 1 as well as figure 2 , the present embodiment discloses a paraffin section dewaxing device, comprising a drug assembly frame 101, a slice lifting assembly 201 and a drug drive assembly 301, the drug assembly frame 101 is a ring-shaped support structure, and a track is arranged on the ring structure, The size of the track is adapted to the drug container 103, and the drug container 103 is inserted into the track of the ring structure and arranged along the track of the ring bracket. The slice lifting assembly 201 is arranged on one side of the drug assembly frame 101, and includes a slice clamp 202 and a lifting rod 203. The lifting rod 203 is vertically arranged and includes more than two telescopic ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com