Coating antifog eyeglass and preparing method thereof

An anti-fog eye and lens technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of inconvenient chemical odor, poor wear resistance and durability, short anti-fog time, etc., to achieve good anti-fog effect, The effect of reducing scattering and ensuring transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The coated anti-fog spectacle lens of the present invention and the preparation method thereof will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

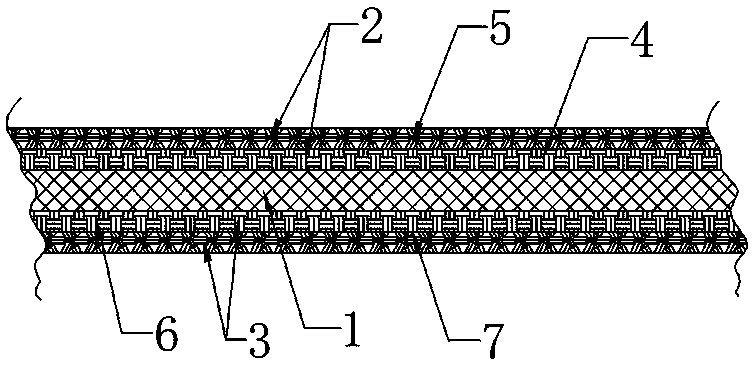

[0020] As shown in the figure, the coated anti-fog spectacle lens of the present invention and its preparation method include a base layer (resin lens) 1 and an upper film anti-fog coating 2 arranged above the base layer and arranged below the base layer The lower anti-fog coating 3, the upper anti-fog coating 2 includes the upper corrosion cross-linked layer 4 and the upper anti-fog layer 5, and the upper film anti-fog coating 2 is formed alternately by the upper corrosion cross-linked layer 4 and the upper anti-fog layer 5 , the lower anti-fog coating 3 comprises a lower corrosion cross-linked layer 6 and a lower anti-fog layer 7, and the lower anti-fog coating 3 is alternately formed by a lower corrosion cross-linked layer 6 and a lower anti-fog layer 7, prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com