Charging gun having good heat conduction and heat dissipation performances

A heat dissipation performance and charging gun technology, which is applied in the field of charging guns, can solve problems such as easy breakage, reduce the heat dissipation effect of the charging gun, and poor heat dissipation effect, and achieve good heat dissipation performance, good heat conduction and heat dissipation performance, and improved heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

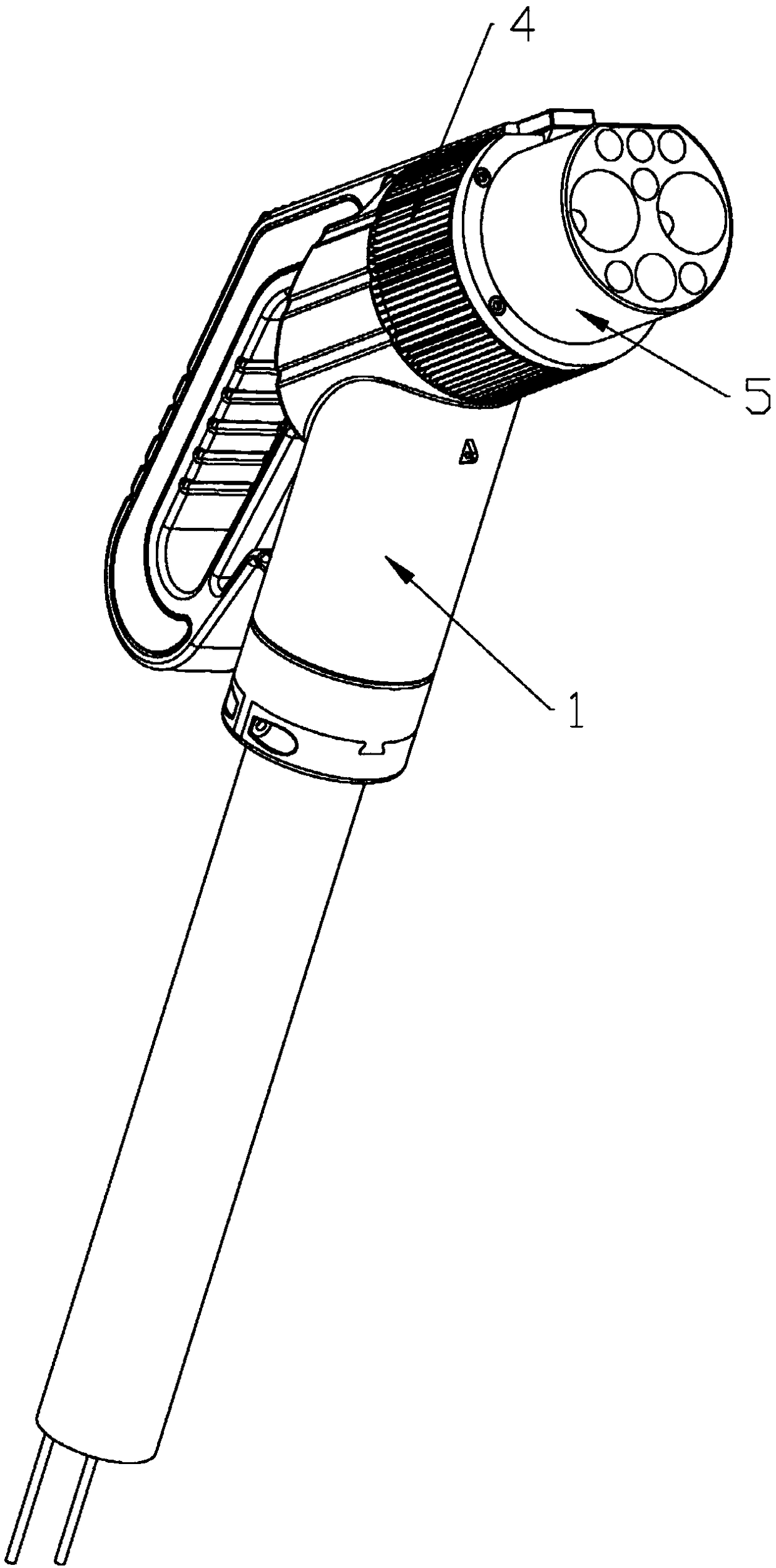

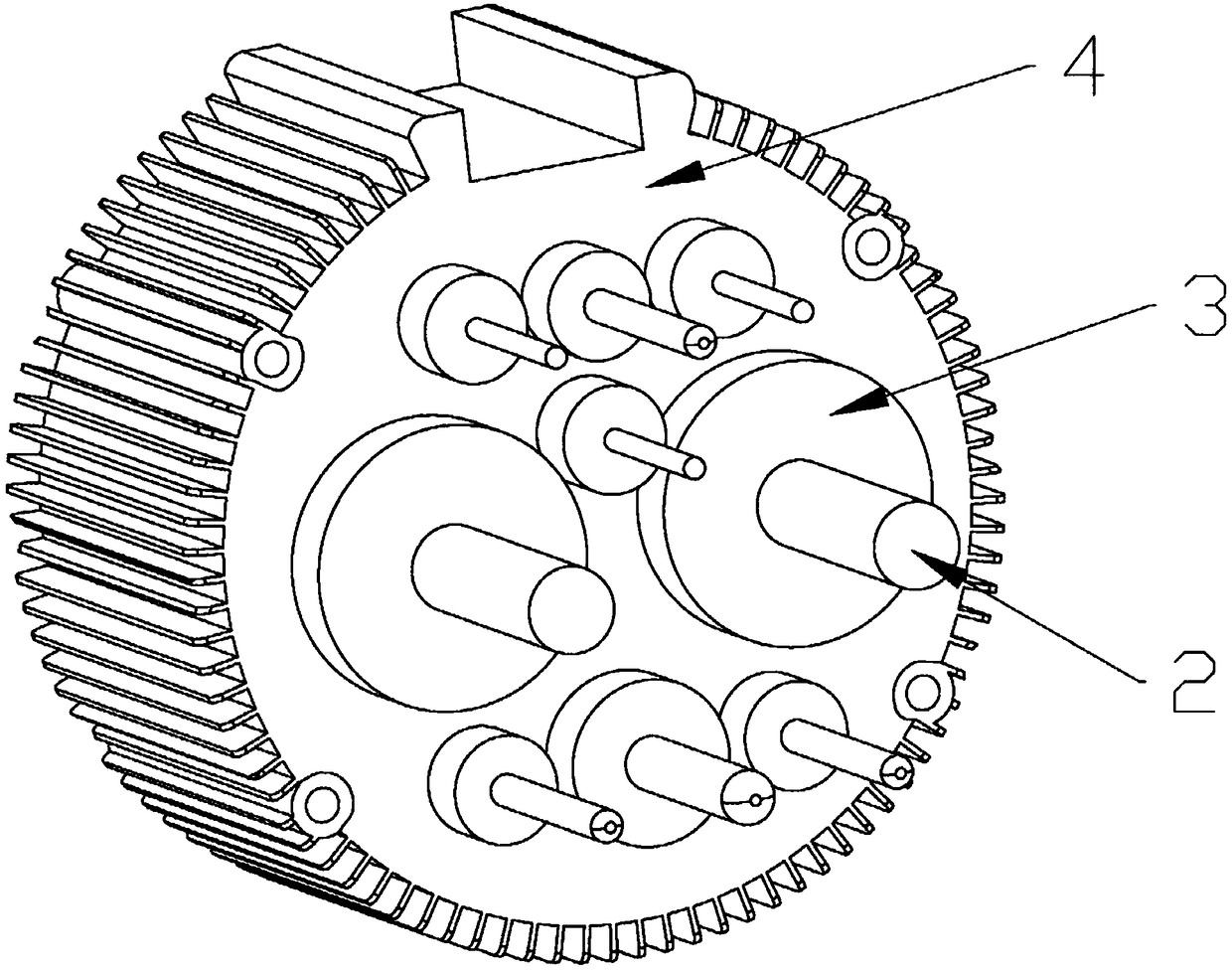

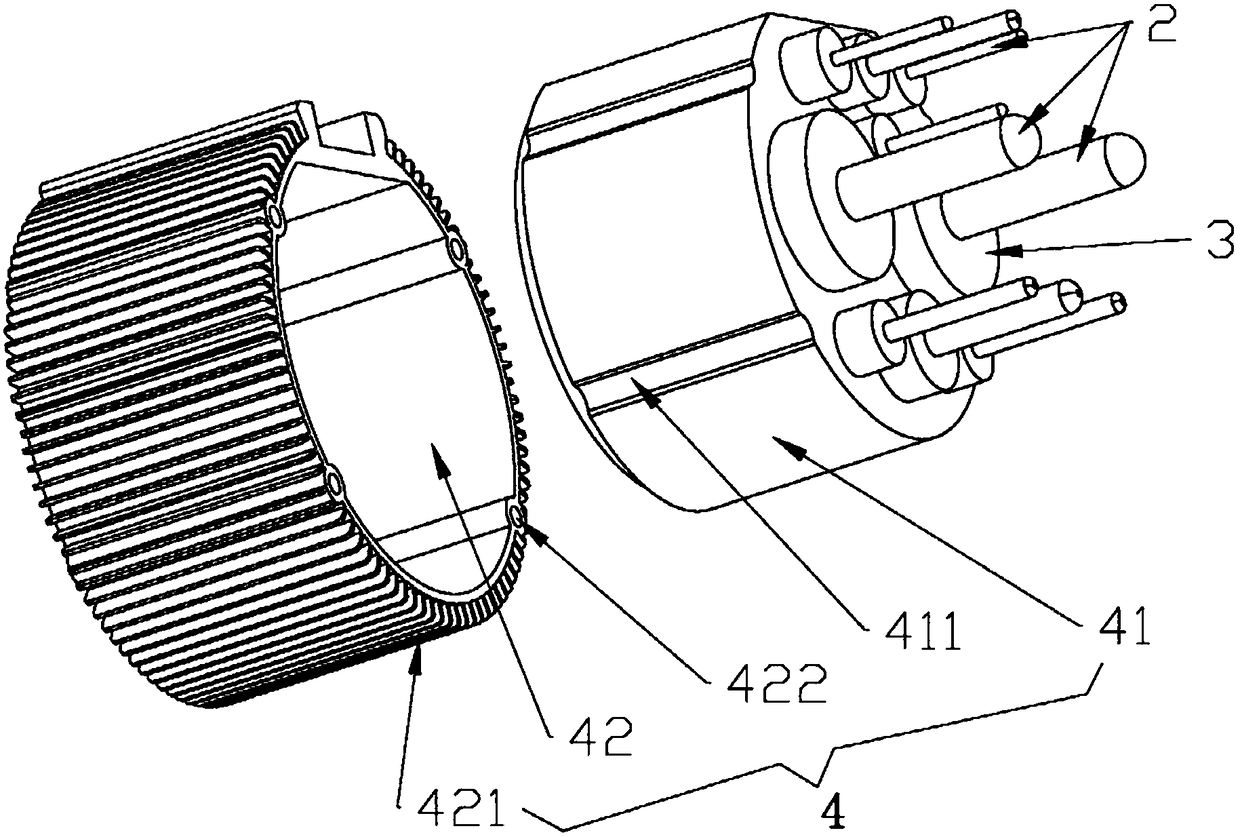

[0035] A charging gun with good heat conduction and heat dissipation performance in this embodiment, such as Figure 1 to Figure 3 As shown, it includes a gun body 1, a terminal 2, an insulating sleeve 3 and a metal heat sink 4, the rear end of the terminal 2 is pierced through the sleeve 3, and the metal heat sink 4 is provided with a mounting hole for passing through the fixed sleeve 3 , The metal radiator 4 is fixed on the gun body 1 . Compared with the prior art, the present invention uses the metal heat sink 4 as the main body of the fixed terminal 2, and the metal heat sink 4 is separated from the terminal 2 by the insulating sleeve 3, thereby avoiding short circuit. The large ceramic part of the traditional fixed terminal 2 is removed, and the difficulty of opening holes in the large-volume ceramic part that is easily broken is avoided. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com