Heat dissipation protective sleeve and method for preparing same

A technology of protective cover and heat-conducting material, which is applied in the field of protective cover, can solve the problem of poor heat dissipation function of mobile phone protective cover, and achieve the effect of solving poor heat dissipation function and good heat conduction and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

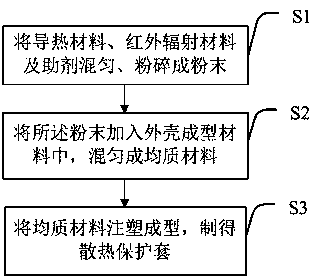

Method used

Image

Examples

Embodiment 1

[0038] (1) Measure 10Kg of TPU elastomer material as component a;

[0039] (2) Measure 0.7Kg of boron nitride, 0.2KG of thermally conductive graphite and 0.1Kg of carbon fiber, as component b;

[0040] (3) Measure 0.2Kg of ferric oxide, 0.2Kg of manganese oxide, 0.1Kg of nickel oxide, 0.1Kg of copper oxide, 0.01Kg of cerium oxide, 3.99Kg of natural cordierite, and 0.99Kg of negative ion powder. After sintering at 1250 degrees under an oxygen atmosphere, the ball mill is crushed into a powder below 5 microns, which is used as component c;

[0041] (4) Measure 10 grams of silane coupling agent, 10 grams of amino coupling agent, and 1000 ml of isopropanol and mix well to form component d;

[0042] (5) Stir components b, c, and d evenly, place them for 24 hours, grind them into powders below 5 microns in a sand mill, and after drying at 180 degrees Celsius, grind them into powders with a particle size of 5 microns in a ball mill to obtain the standby material ;

[0043] (6) The...

Embodiment 2

[0046] (1) Measure 10Kg of PC plastic material as component a;

[0047] (2) Measure 0.7Kg of hexagonal boron nitride powder, 0.25Kg of aluminum oxide powder and 0.05Kg of carbon nanotube as component b;

[0048](3) Measuring tin dioxide 0.2Kg, zinc oxide 0.2Kg, nickel oxide 0.1, copper oxide 0.1, cerium oxide 0.01Kg, light-colored synthetic magnesium cordierite 3.99 mixed and crushed into powder below 20 microns, 1160 under an oxygen-free atmosphere After high-degree sintering, the ball mill is crushed into a powder below 5 microns, which is used as component c;

[0049] (4) Measure 10 grams of titanate coupling agent, 5 grams of vinylpyridine, 5 grams of vinylpyrrolidone, and 1000 ml of isopropanol and mix well to form component d;

[0050] (5) Stir components b, c, and d evenly, place them for 24 hours, grind them into powders below 5 microns in a sand mill, and after drying at 180 degrees Celsius, grind them into powders with a particle size of 5 microns in a ball mill to ...

Embodiment 3

[0054] (1) Measure and take 10Kg of full-component liquid silica gel and prepare it as component a;

[0055] (2) Measure 0.7Kg of hexagonal boron nitride powder, 0.25Kg of aluminum oxide powder and 0.05Kg of carbon nanotube as component b;

[0056] (3) Measuring tin dioxide 0.2Kg, zinc oxide 0.2Kg, nickel oxide 0.1, copper oxide 0.1, cerium oxide 0.01Kg, light-colored synthetic magnesium cordierite 3.99 mixed and crushed into powder below 20 microns, 1160 under an oxygen-free atmosphere After high-degree sintering, the ball mill is crushed into a powder below 5 microns, which is used as component c;

[0057] (4) Measure 10 grams of silane coupling agent, 10 grams of amino coupling agent and 1000 ml of isopropanol and mix well to form component d;

[0058] (5) Stir components b, c, and d evenly, place them for 24 hours, grind them into powders below 5 microns in a sand mill, dry them at 180 degrees Celsius, and grind them into powders with a particle size of 5 microns in a bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com