Modular motor control method and device

A motor control and modular technology, applied in the direction of AC motor control, control system, software algorithm control, etc., can solve the problems of complex control process, low control accuracy and control efficiency, lack of inheritability, etc. Efficiency, simple effect of control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of a modular motor control method and device proposed according to the present invention and its Efficacy, detailed as follows.

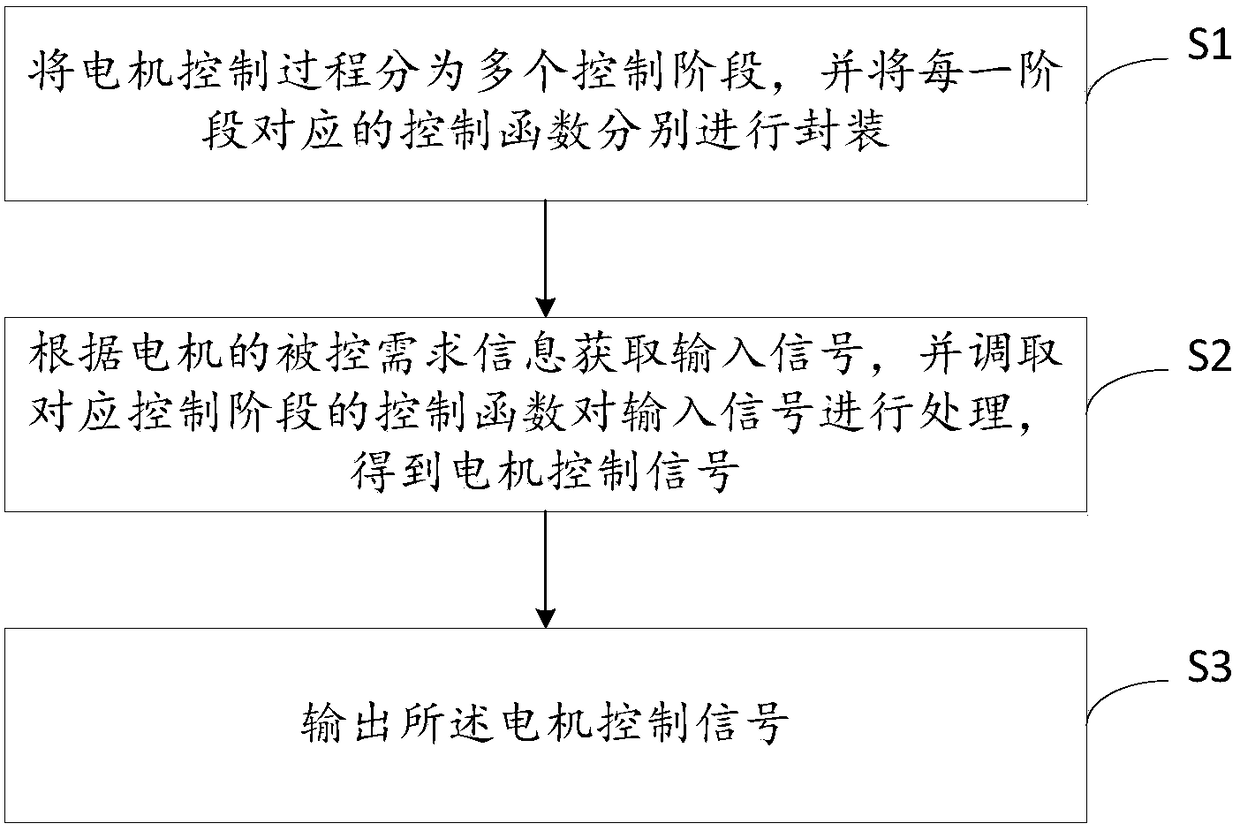

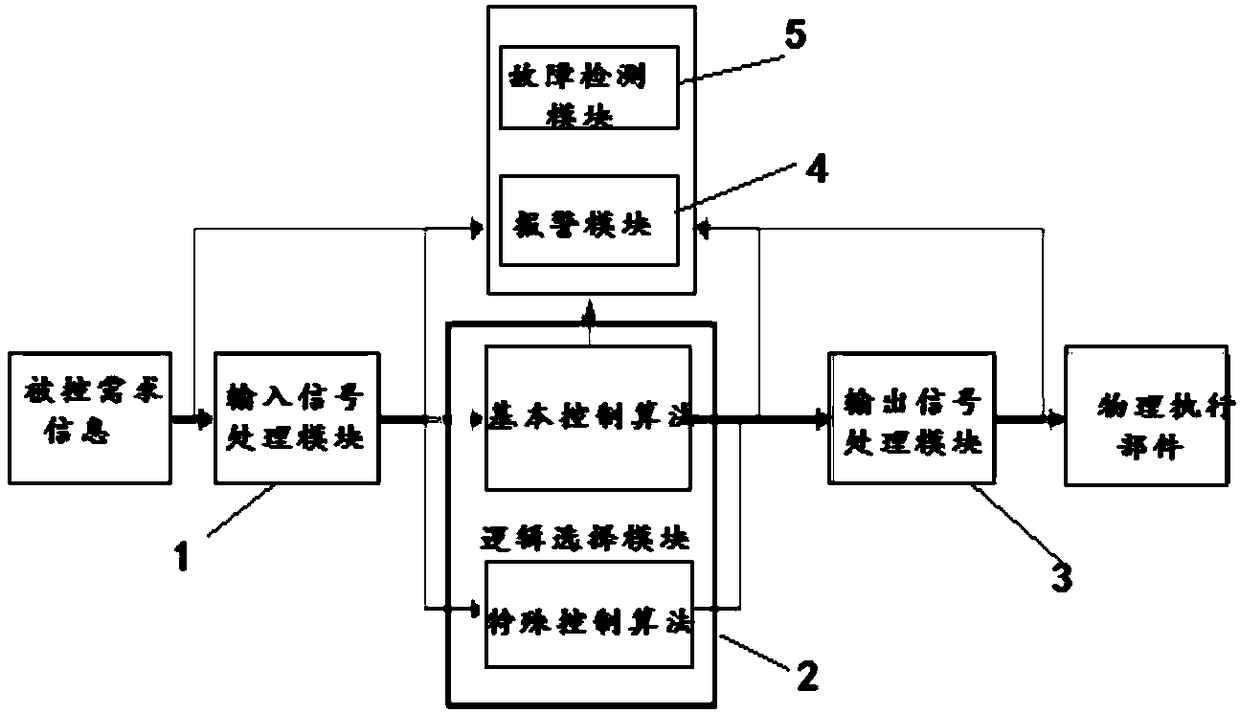

[0050] Such as figure 1 As shown, the embodiment of the present invention provides a modular motor control method, including the following steps:

[0051] Step S1, dividing the motor control process into multiple control stages, and encapsulating the control functions corresponding to each stage;

[0052] Wherein, each control stage can also be divided into multiple sub-control stages.

[0053] As an example, the step S1 specifically includes:

[0054] Step S11, dividing the motor control process into three stages, which are respectively an input signal processing stage, a logic selection stage and an output signal processing stage;

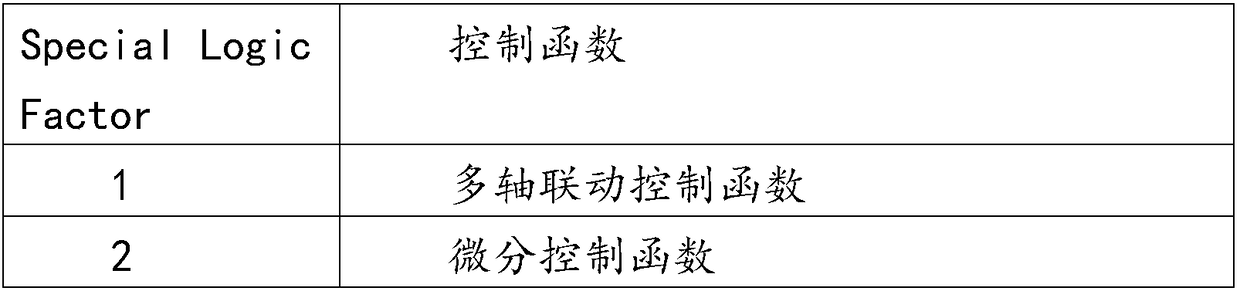

[0055] Among them, the input signal processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com