Moving coil type electroacoustic/acoustoelectric conversion device

An acoustic-electrical conversion, moving coil technology, applied in electrical components, sensors, etc., can solve the problems of uneven magnetic field intensity up and down the column magnet, linear distortion, increased wearing pressure, etc., to achieve good magnetic enhancement effect and reduce linear distortion. , the effect of improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

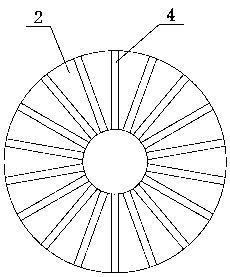

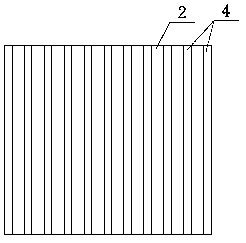

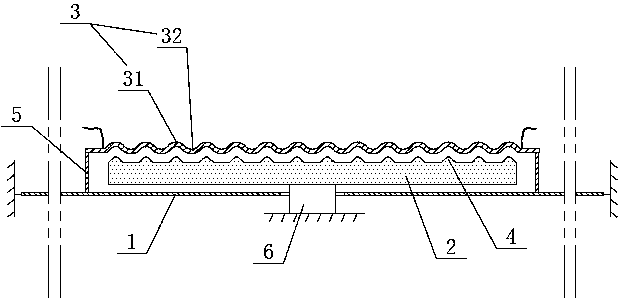

[0030] Referring to the accompanying drawings, the moving coil type electro-acoustic / acoustic-electric conversion device of the present invention comprises a permanent magnet part, a coil part and a diaphragm 1, the permanent magnet part is a planar magnet 2, and the coil part comprises a coil substrate 3 and a built-in coil substrate In the coil winding, the diaphragm 1 and the coil substrate 3 are connected as an integral structure, and the coil substrate 3 is arranged in parallel with the planar magnet 2; Parts 31 and inner recesses 32 are alternately arranged to form a corrugated shape, the shape of the planar magnet 2 matches the shape of the coil substrate 3 and a plurality of ribs 4 are arranged at intervals on the plane corresponding to the planar magnet 2 and the coil substrate 3, each The protruding ribs 4 are arranged correspondingly to the raised portion 31 or the inner concave portion 32 on the coil substrate 3 .

[0031] Wherein, the coil substrate 3 may be circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com