Elbow-shaped longitudinal beam and space extension arm

An extension arm and elbow-shaped technology, which is applied in the field of satellite structures, can solve problems such as the implementation of elbow-shaped longitudinal beams and leaf spring structures that are not specifically introduced, and achieve the effects of facilitating installation and use, large expansion and contraction ratio, and good thermal stability

Active Publication Date: 2014-05-28

XIAN INSTITUE OF SPACE RADIO TECH

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

New York: John Wiley & Sons Inc., 1997 introduced the principle of the space extension arm, but did not specifically introduce the specific structural realization of the elbow longitudinal beam and the leaf spring

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

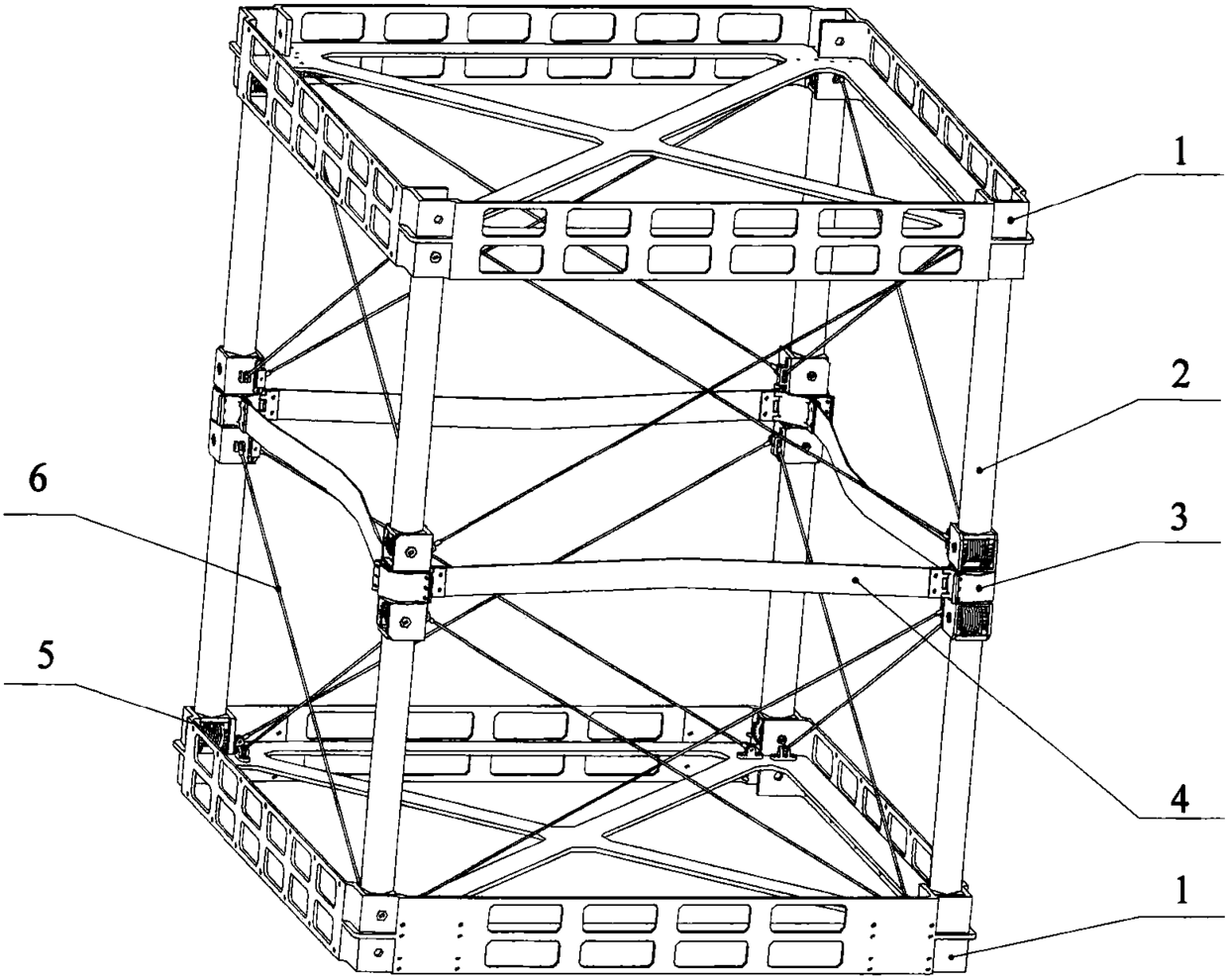

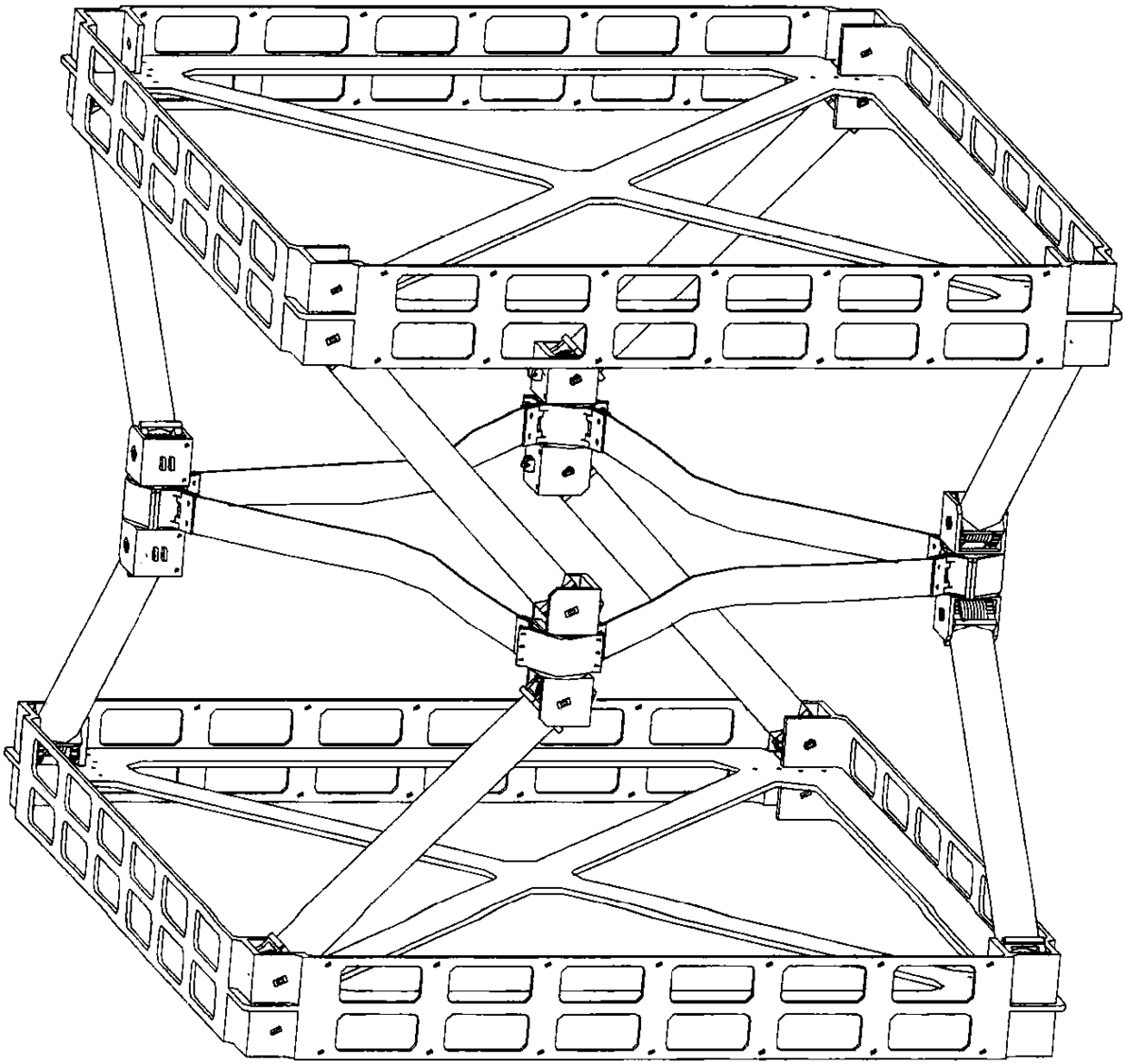

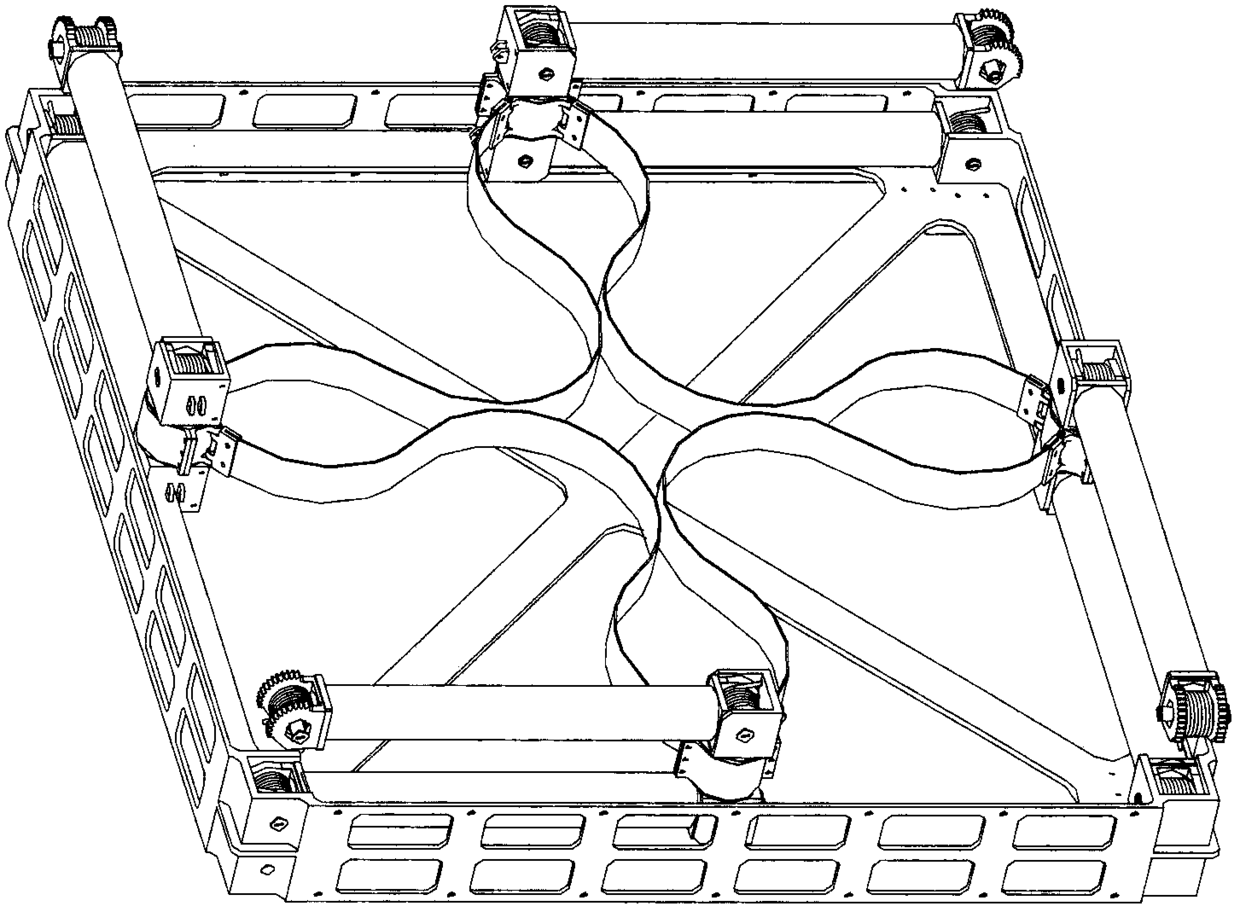

An elbow-shaped longitudinal beam and a space extension arm. The elbow-shaped longitudinal beam is divided into left and right parts with the elbow as the center. The two parts share a middle hinge box, and each part includes a carbon fiber tube, an elbow joint torsion spring, and a rolling bearing. , synchronous gear, sliding bearing, shaft 1, toothed joint 1, shaft 2, guide rod and toothed joint 2; the left and right parts are meshed by synchronous gears; the synchronous gears of each part are installed in the middle of the middle hinge box through shaft 1 Sliding bearings are installed between the shaft one and the synchronous gear; the toothed joint one is installed on both sides of the middle hinge box through the shaft two, and meshes with the above synchronous gears, and the rolling bearing is installed between the toothed joint one and the second shaft; the toothed joint One is connected to one end of the carbon fiber tube, and the other end of the carbon fiber tube is connected to the tooth joint two; the elbow joint torsion spring is installed on the shaft two through the guide rod, and one torsion arm of the elbow joint torsion spring is limited by the middle hinge box, and the other A torsion arm is limited by a toothed joint.

Description

technical field The invention relates to a novel elbow-shaped longitudinal beam and a space extending arm, belonging to the field of satellite structures. Background technique In China, some achievements have been achieved in the research of sleeve rods, disc pressure rods and stay cable locking rods (also called cable-rod stretching arms). When the antenna unit is fixed in multiple directions, the above-mentioned extension arms can only install the antenna at the top of the extension arm due to the limitation of rigidity or folding method, which cannot meet the requirement of fixing the antenna unit in the middle of the extension arm. At present, there is no report on the content of this technology in China. Chen Liemin. Spacecraft Structure and Mechanism. Beijing: China Science and Technology Press, 2005, only briefly introduced the concept and principle of the extension arm, and did not introduce the specific structure details. Foreign literature Conley P L. Space Vehic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B64G1/66B64G1/22

Inventor 王锋斌史明杨俊良周丽萍

Owner XIAN INSTITUE OF SPACE RADIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com