a stick g-c 3 no 4 @snin 4 the s 8 Composite photocatalyst and preparation method thereof

A technology of g-c3n4 and composite light, which is applied in the fields of physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of long time, high synthesis temperature, fast electron and hole recombination, etc. problem, to achieve the effect of reducing the recombination rate and easier separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The chemical reagents used in the present invention are all analytically pure, purchased from Aladdin Reagent Company, and the experimental water is deionized water. Specific steps are as follows:

[0033] (1) Preparation of pure g-C 3 N 4 : Weigh 30 g of urea and place it in a crucible, dry it in an oven at 80°C for 8 h, and stir once every 1 h to ensure that the urea is fully dried. Place in a muffle furnace, raise the temperature to 550°C at a rate of 10°C / min, and keep the temperature constant for 2 h. Cool to room temperature and grind to obtain a pale yellow solid (pure g-C 3 N 4 ).

[0034] (2) Preparation of g-C 3 N 4 @SnIn 4 S 8 Composite photocatalyst: 0.5559 g of g-C 3 N 4 powder (molecular weight: 92, 6.042 mmol) and 0.07012 g SnCl 4 • 5H 2 O (molecular weight: 350.60, 0.2 mmol) was dissolved in 80 mL of deionized water, and after sonication for 40 min, 0.2407 g of In(NO 3 ) 3 • 5H 2 O (molecular weight: 300.83, 0.8 mmol), 0.2341 g of C 2 h ...

Embodiment 2

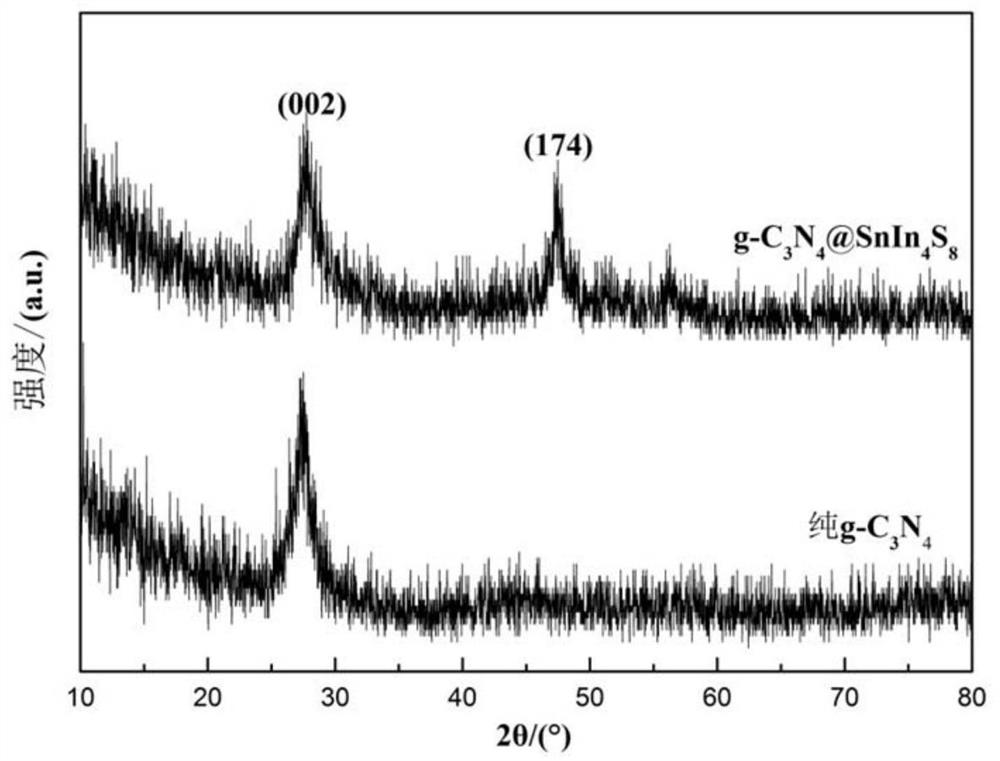

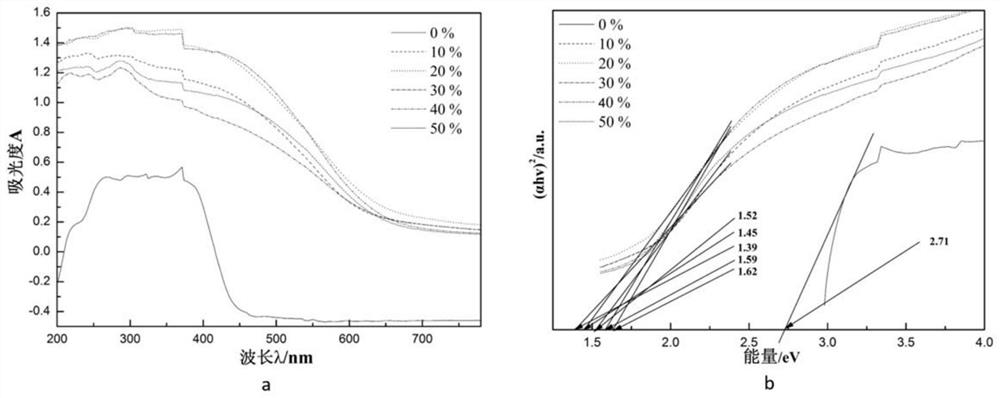

[0037] The preparation method of embodiment 2 is identical with embodiment 1, just pure g-C 3 N 4 with SnIn 4 S 8 The mass ratio is set to different loading gradients, and photocatalysts with different loading ratios are prepared, which are changed to 10%, 20%, 40%, and 50% g-C 3 N 4 @SnIn 4 S 8 composite photocatalyst. X-ray diffraction pattern (XRD) as Figure 6 As shown, g-C appeared in the composite sample 3 N 4 and SnIn 4 S 8 characteristic peaks, indicating that g-C 3 N 4 with SnIn 4 S 8 compounded successfully. At the same time, the corresponding g-C after compounding 3 N 4 The intensity of the diffraction peak (002) crystal plane decreases with the increase of the loading ratio, which is mainly due to the fact that the SnIn 4 S 8 The addition of SnIn makes the 4 S 8 Crystals covered in g-C 3 N 4 surface, inhibiting the g-C 3 N 4 growth, making g-C 3 N 4 The intensity of the diffraction peaks was significantly reduced. Compared Figure 4 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com