Downstream roller replacing method achieving online roller replacing of ESP finish rolling unit

A technology of finishing rolling mills and rolling rolls, applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve the problems affecting the production efficiency of continuous casting and rolling of thin slabs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0064] There are a total of 30 possible combinations in the roll change of the rolling mill in the 5+1 mode, and the countercurrent roll change method can solve 15 of them, that is, the downstream rack replaces the upstream rack, and the other 15, that is, the standby rack is located When the roll frame is upstream, that is, the upstream frame replaces the downstream frame, it cannot be solved by the countercurrent method, so it needs to be solved by the downstream roll change method.

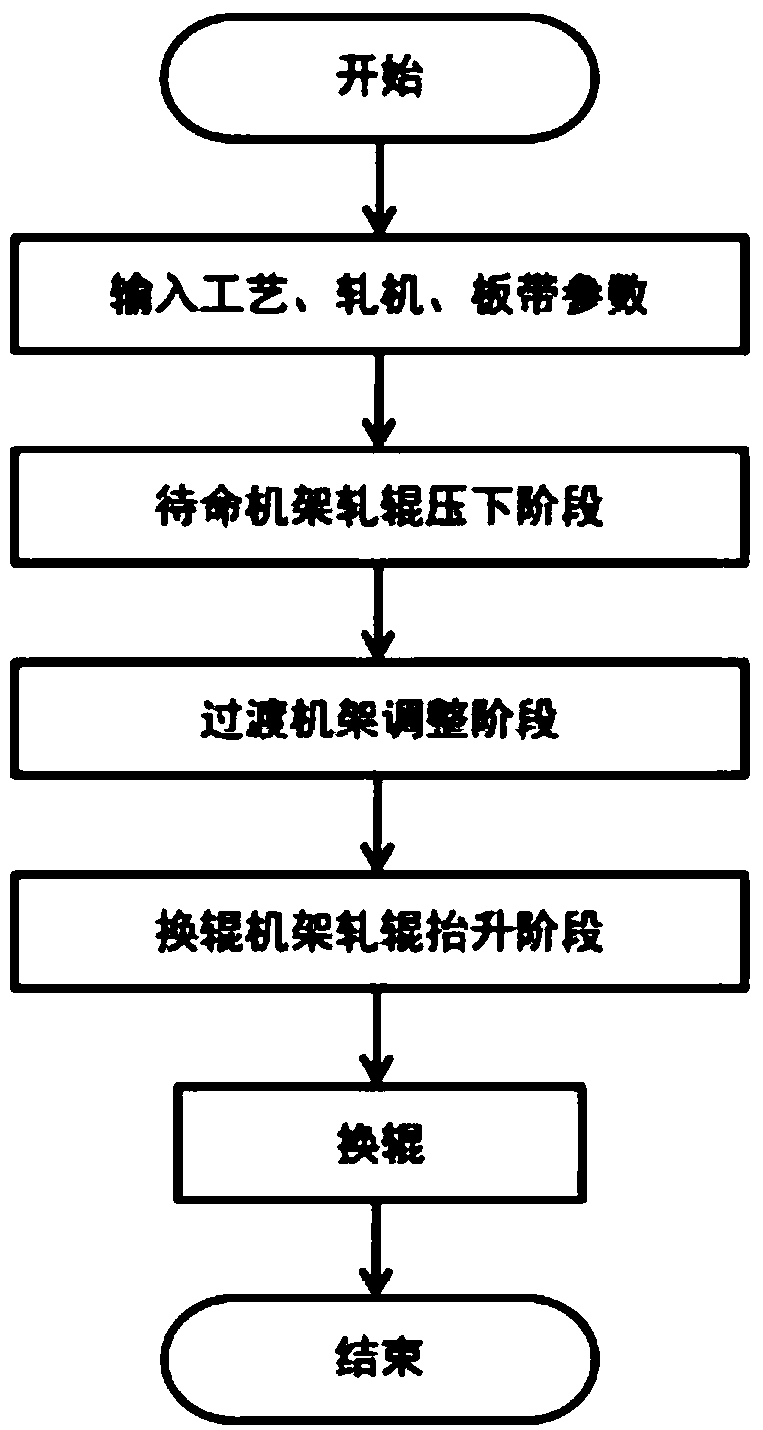

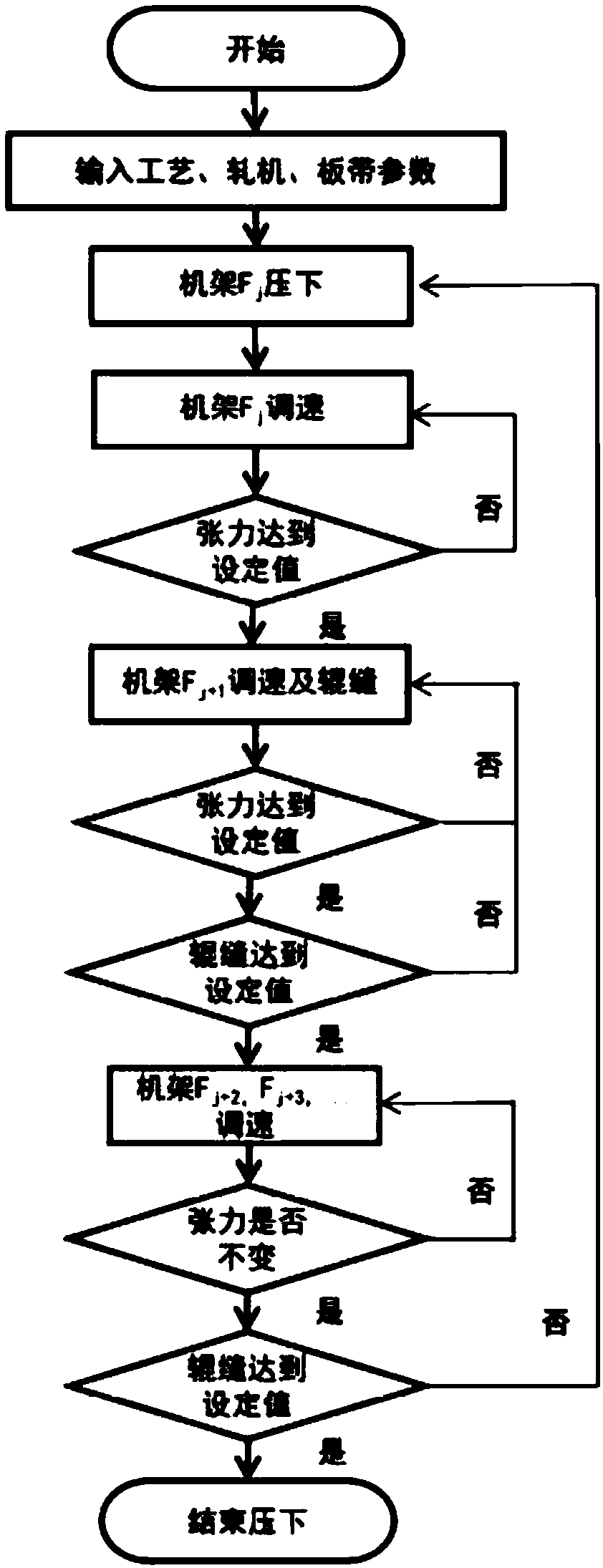

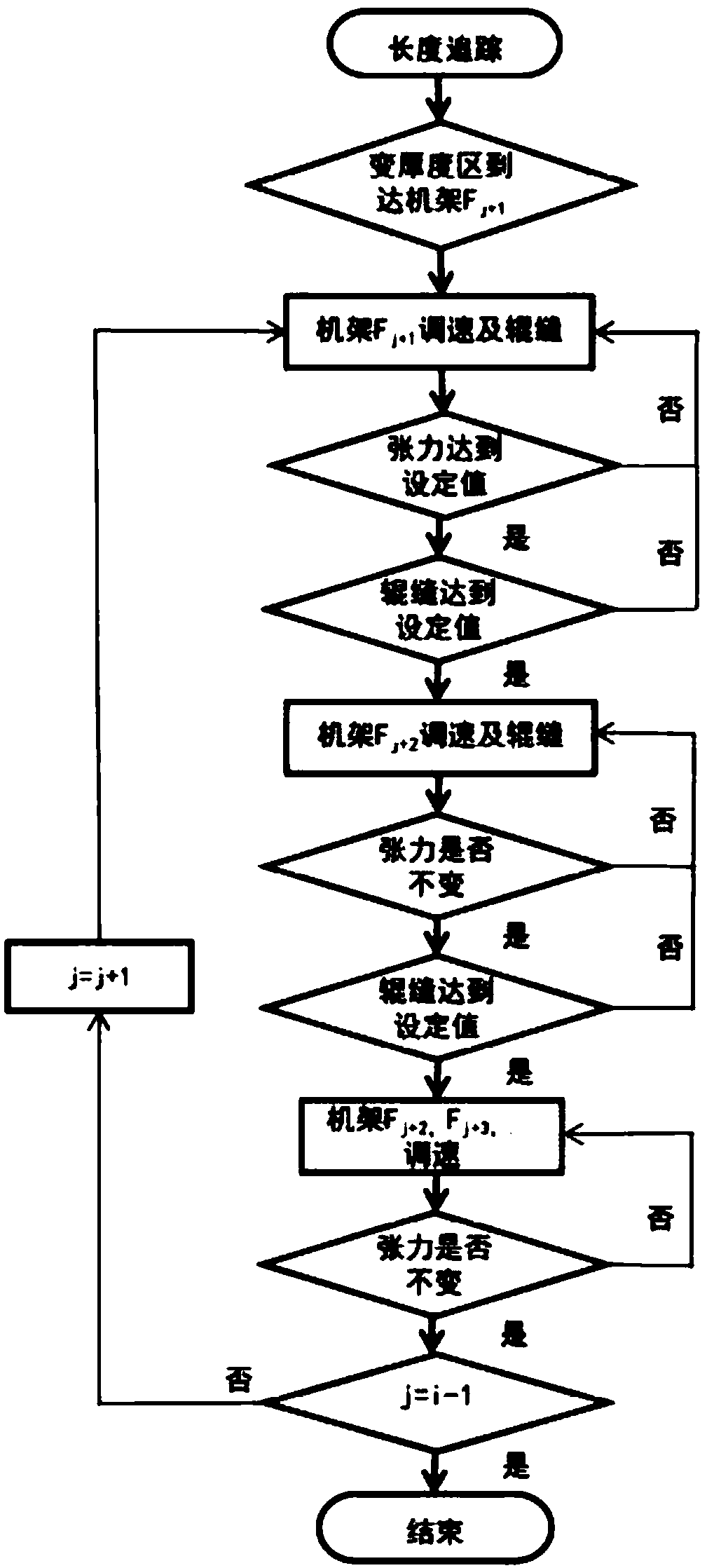

[0065] refer to Figure 1~4 , a kind of down-stream roll change method that realizes the ESP finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com