Plate positioning device of plate shearing machine

A technology of positioning device and shearing machine, which is applied to the attachment of shearing machines, shearing devices, shearing machine equipment, etc., which can solve the problems of laborious, unsuitable for large-scale shearing operations, and many steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

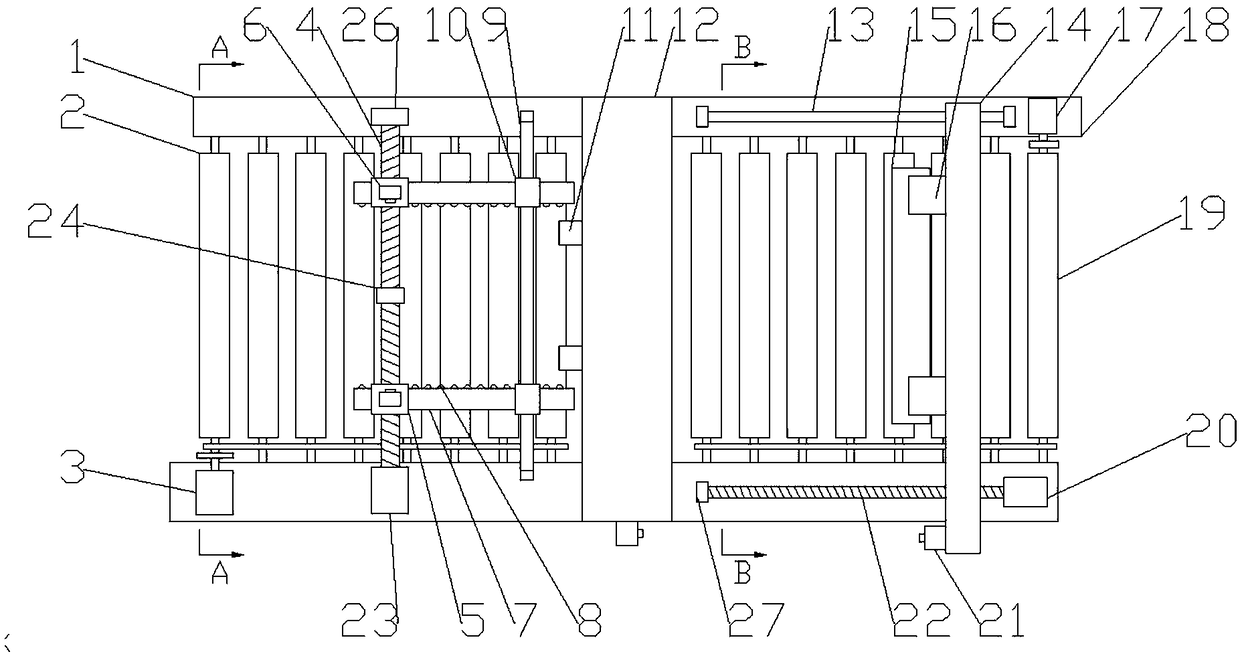

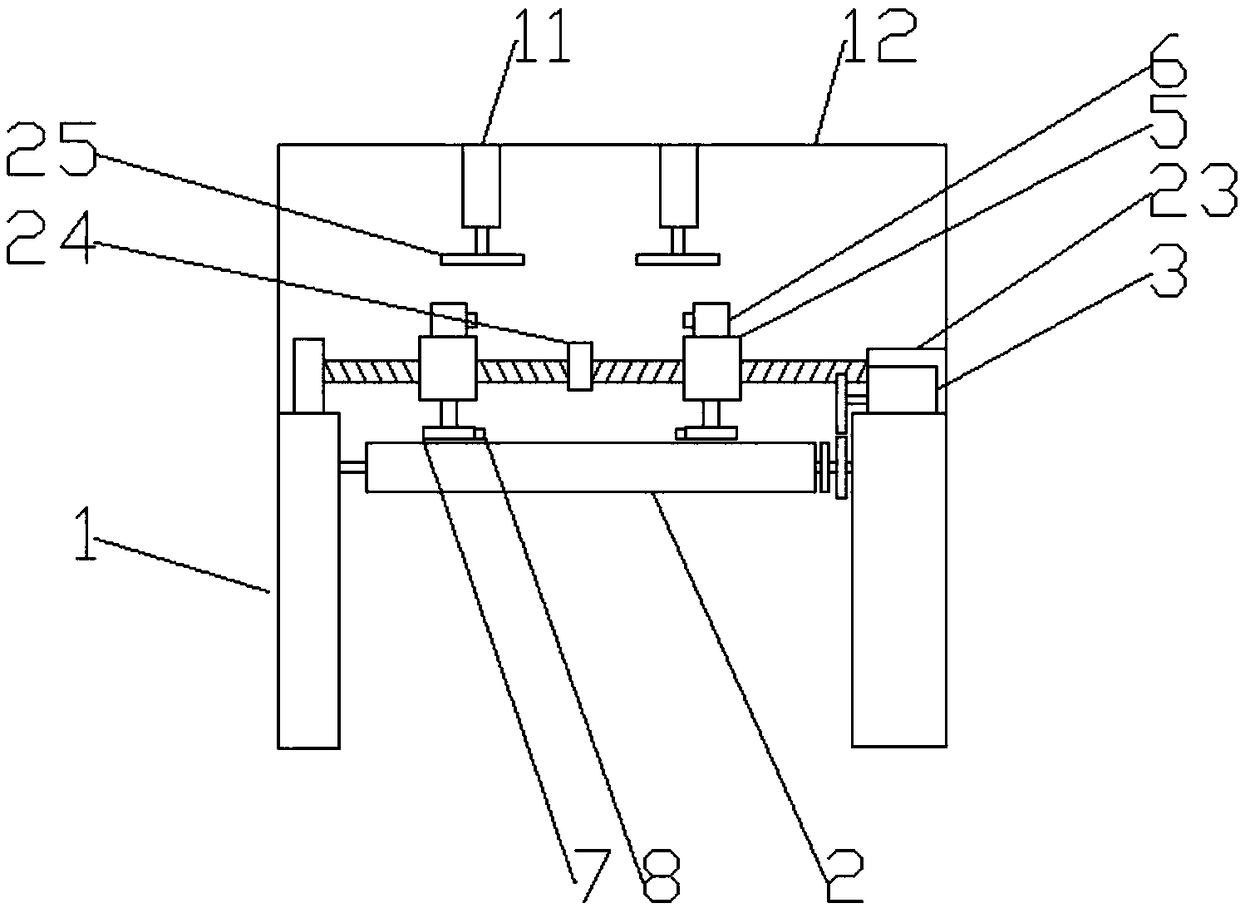

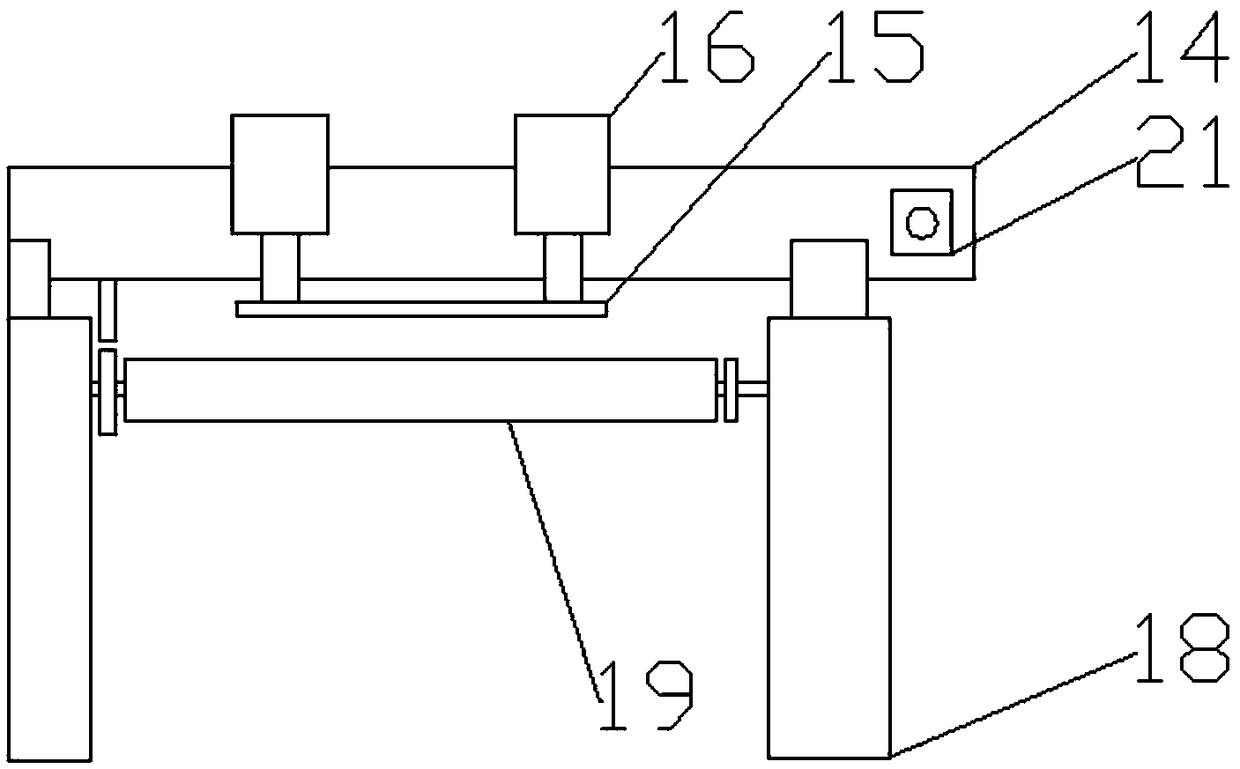

[0015] Figure 1-3 A specific embodiment of the present invention is shown: a plate positioning device for a shearing machine, comprising a shearing machine body 12, a front support 1 is provided at the front end of the shearing machine body 12, and a rear support 18 is provided at the rear end. Front support 1 one end is provided with screw mandrel seat one 26, and the other end is provided with servo motor one 3 and servo motor four 23, and described screw mandrel seat one 26 is provided with two-way screw mandrel 4, and described two-way screw mandrel 4 one end is connected with servo motor Motor four 23 are connected, and described two-way screw mandrel 4 is provided with symmetrical sliding seat 5, and described sliding seat 5 is provided with two distance sensors one probe, and described front bracket 1 upper end is also provided with two-way screw mandrel 4 parallel. The slide bar-9 is provided with a symmetrical slider 10 on the slide bar-9, the lower end of the slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com