Plate shearing mechanism of plate shearing machine

A shearing machine and shearing technology, applied in the field of machinery, can solve the problems of limited material range, fracture separation, weak impact resistance, etc., and achieve the effect of improving the safety of use, prolonging the service life, and strong impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

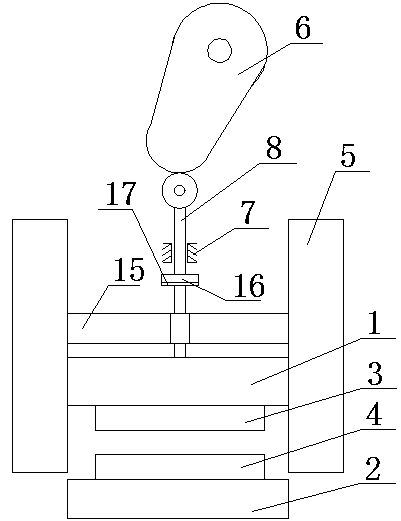

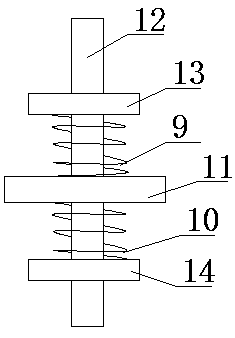

[0017] figure 1 with figure 2 A specific embodiment of the present invention is shown: a shearing mechanism of a shearing machine, including a moving tool seat 1, a fixed tool seat 2, a moving tool 3, a fixed tool 4, a buffer module 5, a cam 6, a slide rail 7 and a roller pusher Rod 8, the buffer module 5 has two, the two ends of the movable tool holder 1 are respectively connected with the two buffer modules 5, the cam 6 is connected to the frame through bearing rotation, and the slide rail 7 is fixedly connected On the frame, the bottom end of the roller push rod 8 is fixedly connected with the top end of the movable tool seat 1, and the top end of the roller push rod 8 is connected with the cam 6 by a line contact with the roller, and the movable tool 3 is connected with the movable tool seat 1. 1 is fixedly connected, the fixed tool 4 is fixedly connected to the top of the fixed tool seat 2, and the bottom end of the fixed tool seat 2 is fixedly connected to the frame. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com