Dual-permanent-magnet-pole alternating magnetic field magnetic grinding machining device

An alternating magnetic field and magnetic grinding technology, which is applied in metal processing equipment, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of long processing time and low efficiency, and achieve good surface quality, good economy, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

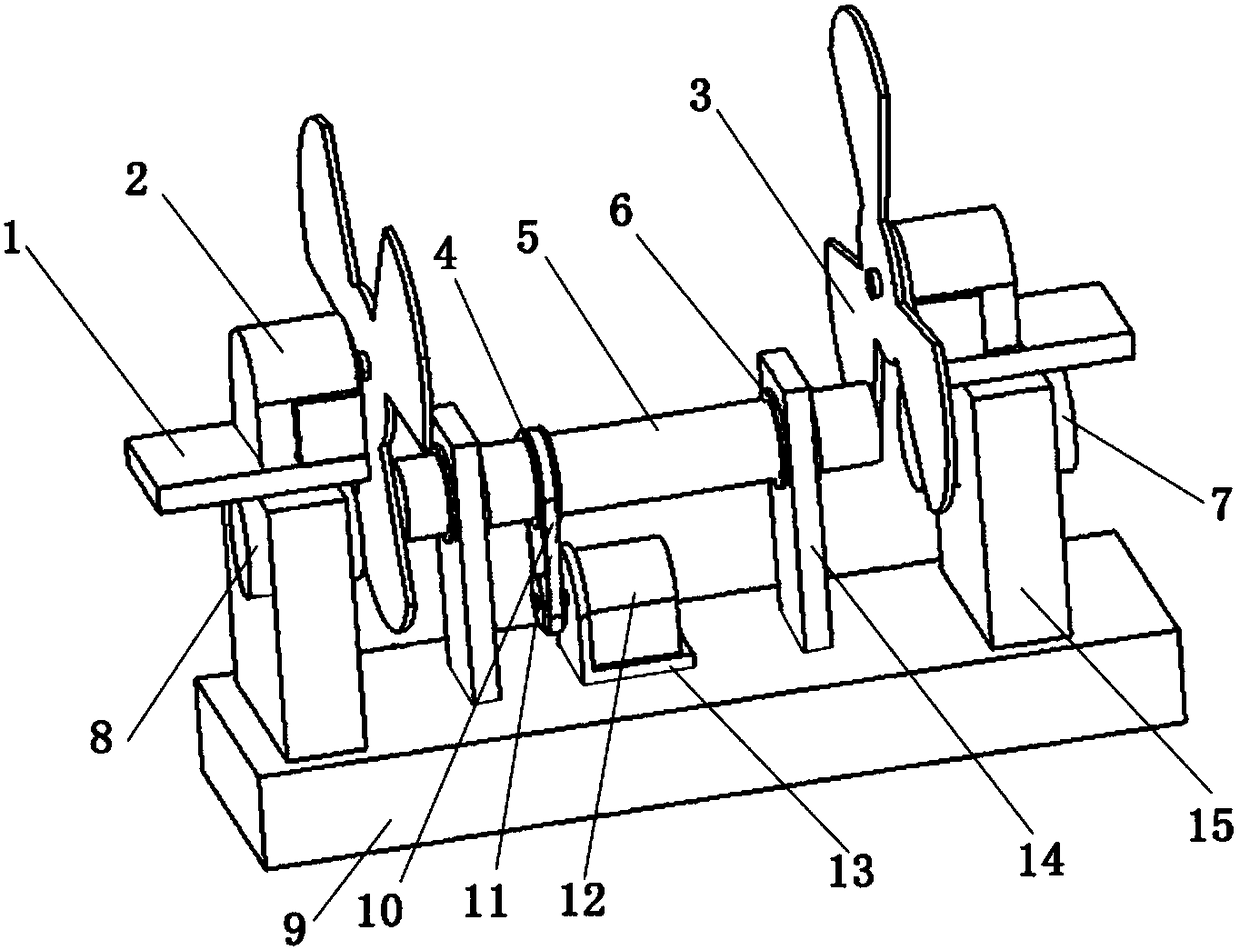

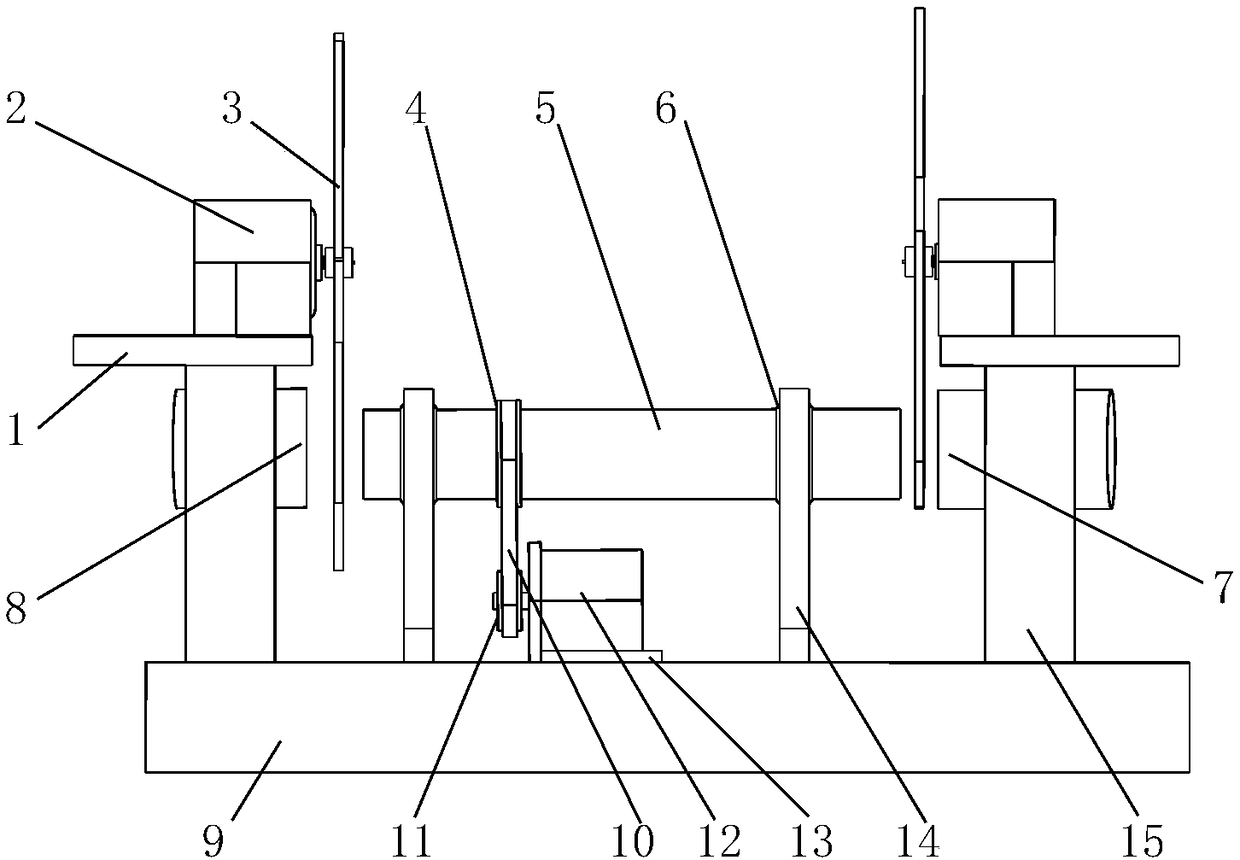

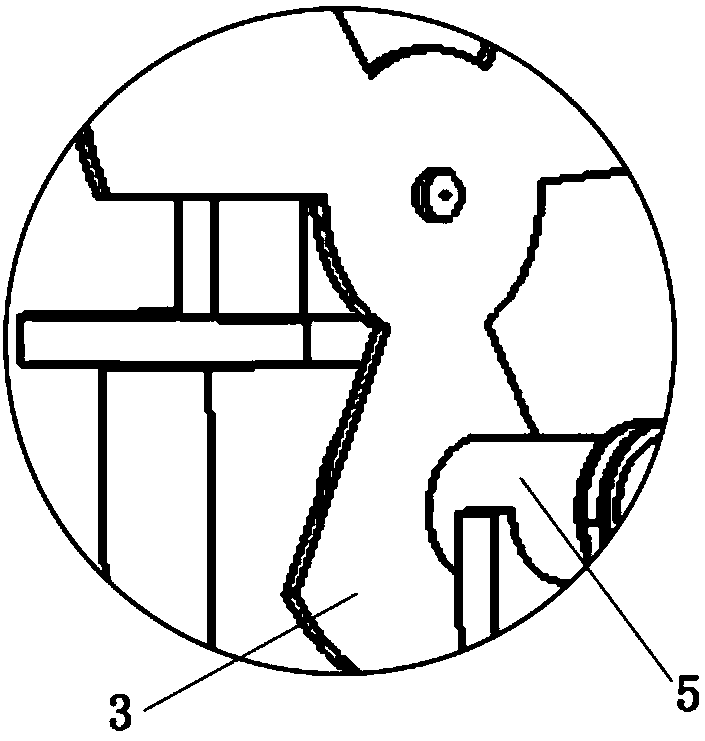

[0024] See figure 1 , figure 2 , double permanent magnetic pole alternating magnetic field magnetic grinding processing device, including support base 15, base 9, magnetic poles, motor with shield 2, shielding disc 3, transmission mechanism, cylindrical mold 5, magnetic abrasive grains, support base 15 installed on the base 9, the magnetic poles are installed on the support base 15, and the motor with shielding cover 2 is fixed above the magnetic poles, and is supported and fixed by the motor base 1. In order to prevent the permanent magnetic pole magnetic field generated by the magnetic poles from interfering with the motor, a magnetic shielding cover is installed outside the motor. Become band shield motor 2. There are two magnetic poles, na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com