Door plate hot-pressing device

A hot pressing device and door panel technology, which can be applied to veneer presses, plywood presses, wood processing equipment, etc., and can solve the problems of poor aesthetics and other issues

Active Publication Date: 2018-08-17

CHONGQING SHUANGCHI DOORS & WINDOWS

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Because the wooden board needs to be polished and cut, there is a lot of dust floating in the air in the workshop where the composite door is produced, and the dust is easy to fall on the placement board. Under the action of pressure, it is embedded in the surface of the board. After the dust falls off, grooves will be formed on the surface of the board. When painting or pasting, the grooves will form depressions, which will deteriorate the aesthetics of the final door.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

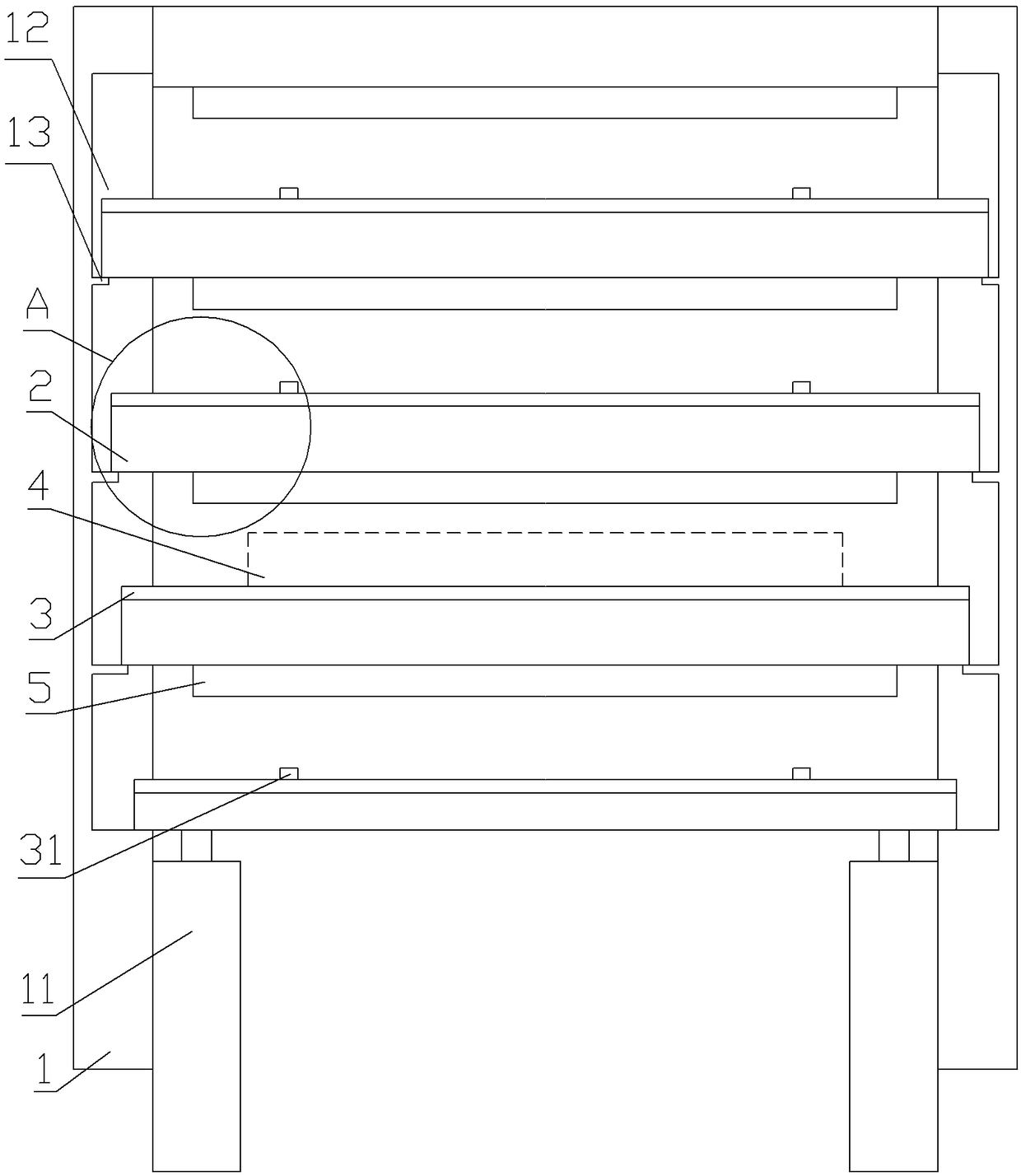

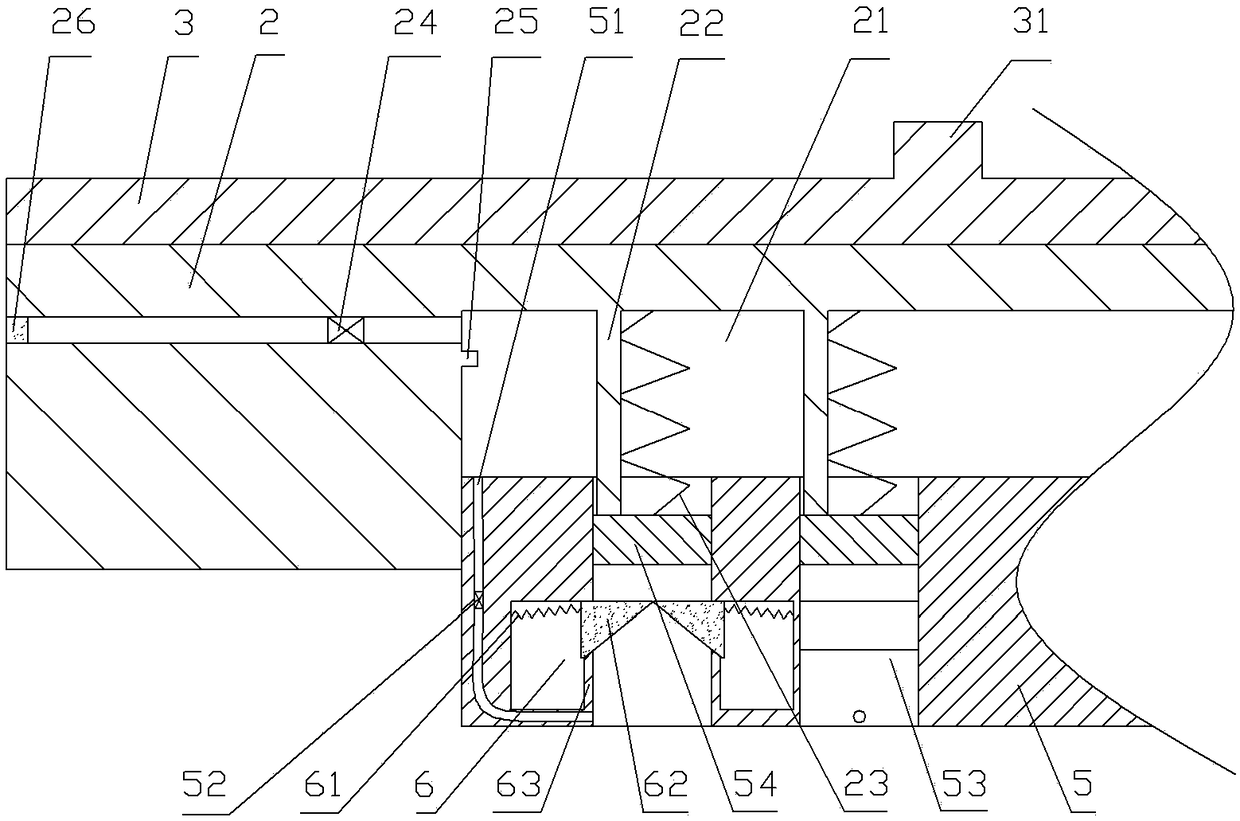

The invention relates to the field of furniture manufacturing, in particular to a door plate hot-pressing device which comprises a rack, a lifting mechanism and a placing mechanism. The lifting mechanism comprises a lifting hydraulic jack; the placing mechanism comprises slide rails and support plates; check blocks are distributed on the slide rails; a top plate is fixed to the top part of the rack; air storage cavities are arranged on the bottom parts of the top plate and the support plates; air inlet check valves are fixed to side walls of the air storage cavities; filter screens are fixed outside the air inlet check valves; dedusting plates are arranged under the bottom arts of the top plate and the support plates; dedusting mechanisms are arranged on the dedusting plates, and comprisetop rods, dedusting channels, pistons and grooves; tension springs are arranged in the dedusting channels; air outlet channels are arranged on the dedusting plates and communicate with the dedusting channels; air outlet check valves are fixed into the air outlet channels; cleaning blocks and compression springs are arranged in the grooves; cleaning layers are fixed to the top parts of the grooves;and abutting blocks are fixed to the port parts of the grooves. According to the scheme, dust on the hot-pressing device can be automatically cleaned.

Description

technical field [0001] The invention relates to the field of furniture manufacturing, in particular to the field of composite door manufacturing. Background technique [0002] Composite doors are widely used in civil and commercial buildings and residences. There are materials that can increase the strength of the doors inside the composite doors, and patterns can be engraved on the wooden boards on the surface. Finally, the surface of the wooden doors can be painted with different colors of paint to make the wooden doors have different characteristics. Different colors and textures are used to meet the aesthetics of different consumers, so the composite door is strong, practical and beautiful at the same time. [0003] When producing composite doors, it is necessary to overlap plates of different materials, then apply glue between adjacent plates, and then send them to a heat press for heat pressing. A heat press generally includes a frame and a plurality of placement plat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27M3/18B27D3/00

CPCB27D3/00B27M3/18

Inventor 文泉

Owner CHONGQING SHUANGCHI DOORS & WINDOWS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com