Method for large-proportion utilization of lump ores for blast furnace

A blast furnace, high-temperature technology, applied in the field of large-scale use of lump ore in blast furnaces, can solve problems such as the deterioration of economic and technical indicators of blast furnaces, hinder the development of edge airflow, and the bonding of blast furnace body, achieve good air permeability index, reduce furnace charge The cost of raw materials and the effect of reducing the energy consumption of the blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

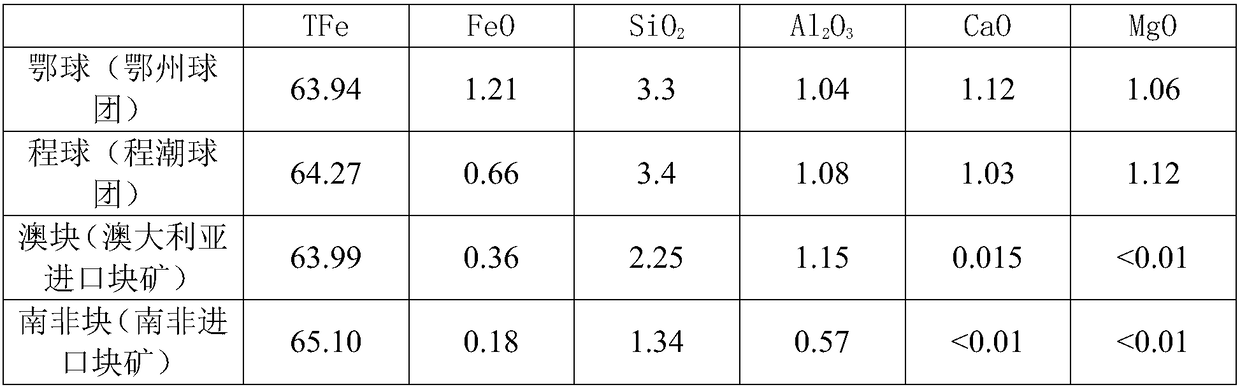

[0039] The softening temperature of No. 4 blast furnace sinter in a domestic ironworks is 1226℃, the softening end temperature is 1351℃, and the softening temperature range is 125℃;

[0040] The No. 4 blast furnace has 9 tons of Australian blocks and 1 ton of coke diced, and the two are fully mixed.

[0041] The conventionally adopted batch weight for No. 4 blast furnace is 60t;

[0042] The No. 4 blast furnace adopts the method of feeding lump ore into the furnace in batches, and the order of distribution is: coke, sintering + jaw balls, Australian lumps + coke;

[0043] The No. 4 blast furnace adopts the distribution matrix from the outer ring to the inner ring, and the charging matrix is: Among them, C is coke, O here represents sintering + jaw ball, K is Australian block + coke, the number on the upper right is the corner position of the cloth, and the number on the lower right is the number of cloth rings corresponding to the number on the upper right. When coke is pl...

Embodiment 2

[0046] The softening temperature of No. 4 blast furnace sinter in a domestic ironworks is 1227°C, the softening end temperature is 1345°C, and the softening temperature range is 118°C; the softening temperature of Australian block is 1053°C, the softening end temperature is 1239°C, and the softening temperature range is 186°C;

[0047] The No. 4 blast furnace has a charge of 12 tons of Australian lumps and 0.8 tons of coke dices, and the two are fully mixed.

[0048] The conventionally adopted batch weight for No. 4 blast furnace is 60t;

[0049] The No. 4 blast furnace adopts the method of feeding lump ore into the furnace in batches, and the order of distribution is: coke, sintering, Australian lump + coke;

[0050] The No. 4 blast furnace adopts the distribution matrix from the outer ring to the inner ring, and the charging matrix is: Among them, C is coke, O here stands for sintering, K is Australian block + coke, the upper right number is the cloth corner position, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com