Parallelly-hanging piece, composite wall plate, wall structure and construction method

A wall structure and pendant technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as door and window installation problems, installation problems, etc., and achieve the effect of good construction efficiency and high construction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

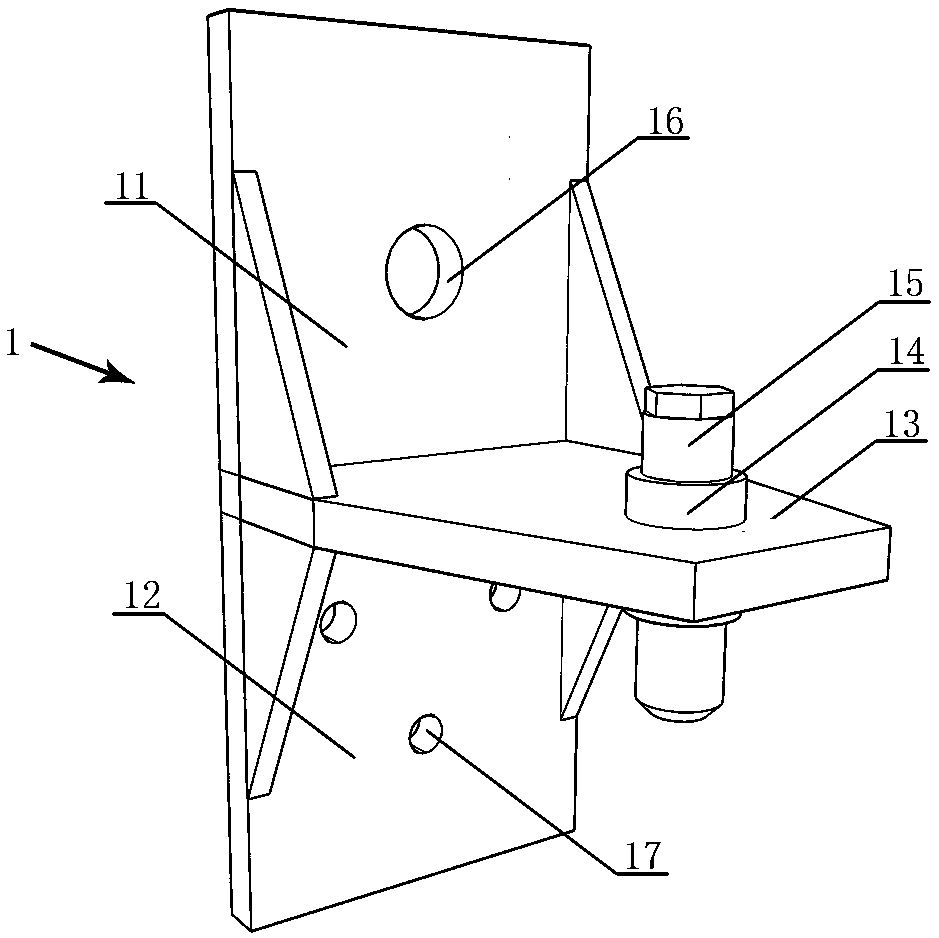

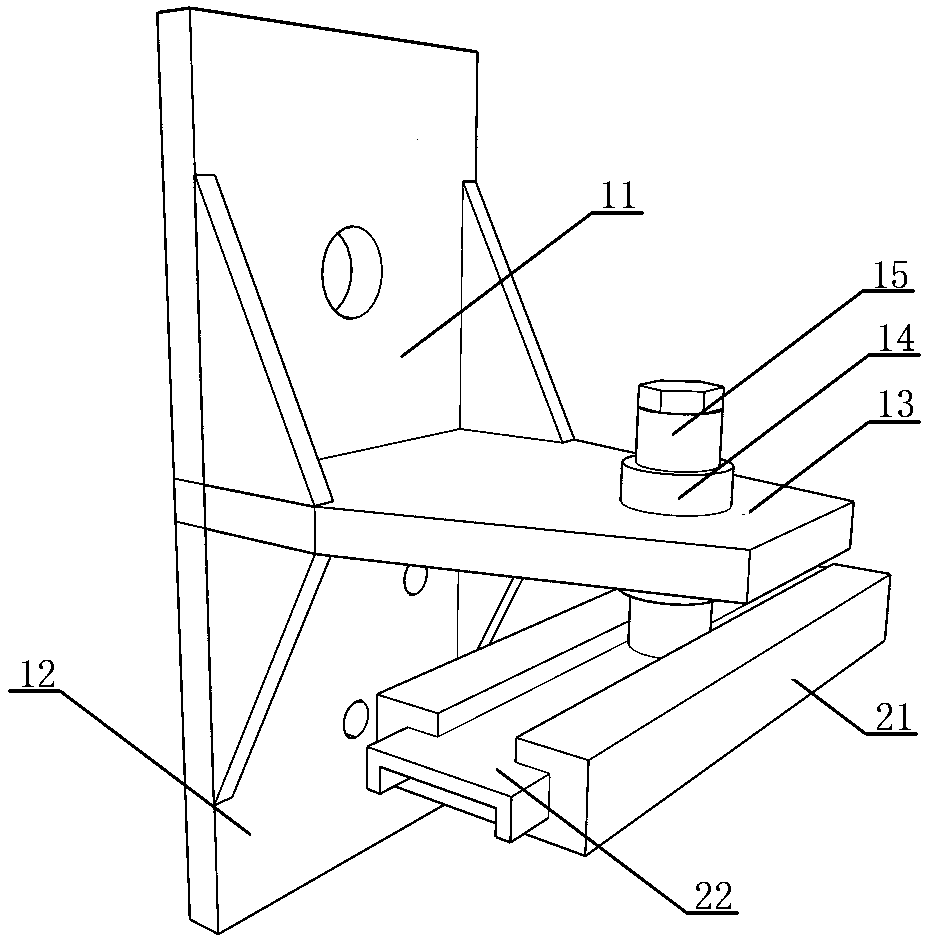

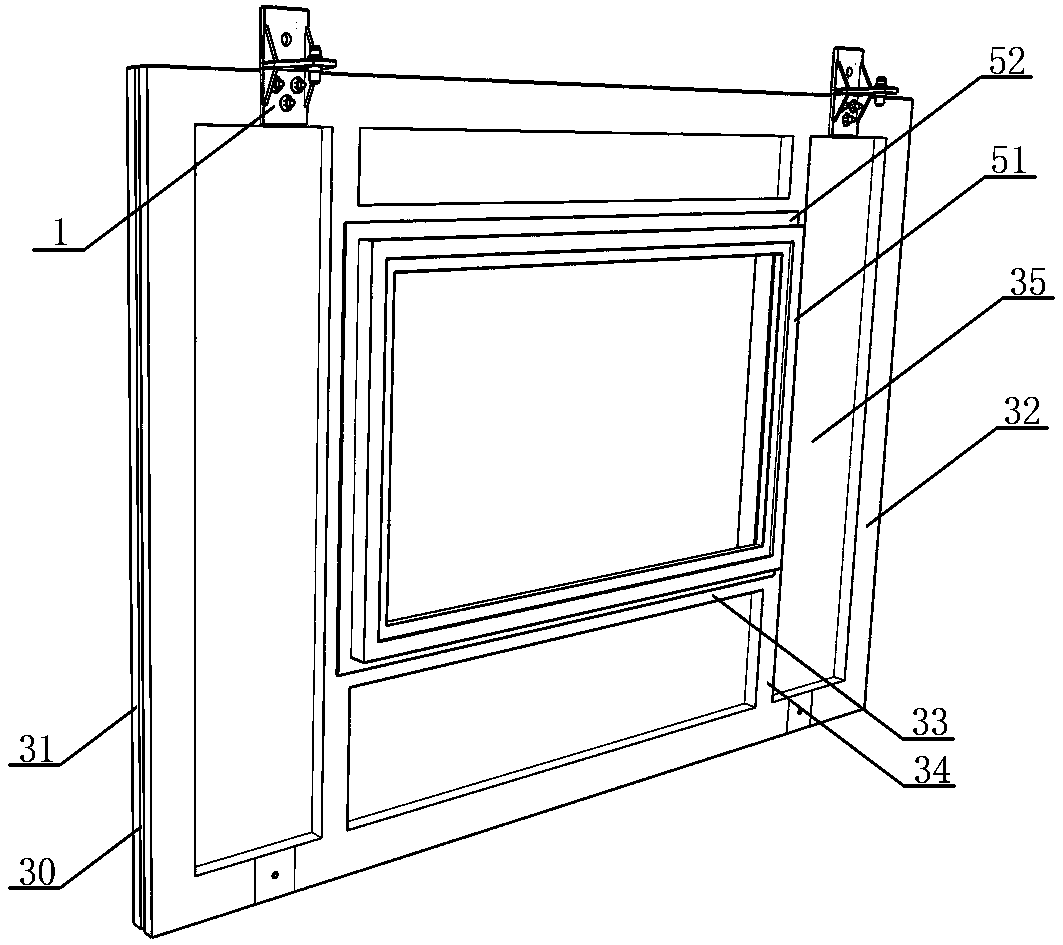

[0066] Examples see figure 1 As shown, this parallel hanging piece, the said parallel hanging piece 1 is a transition piece between the prefabricated wall panel and the building structure; the said parallel hanging piece 1 is a horizontal T-shaped metal processing part, including the vertical upper lug plate 11, the vertical lower lug plate 12, and a horizontal lug plate 13 that is located between the vertical upper lug plate and the vertical lower lug plate and protrudes horizontally from the inside of the two; the vertical upper lug plate 11 is provided with at least one first connecting hole 16, Form the joint of the plate; the vertical lower ear plate 12 is provided with at least two second connecting holes 17 to form the upper plate joint; the horizontal ear plate 13 is vertically and threadedly connected with fastening bolts 15 to form a structural joint ; The parallel hanging piece forms a three-joint integrated hanging piece with the board joint, the upper board joint,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com