Ground fracture area tunnel lining structure based on shield tunnel and construction method of ground fracture area tunnel lining structure

A technology of shield tunneling and ground fissures, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve problems such as poor geological conditions, unfavorable engineering quality control, unfavorable engineering investment control, etc., and achieve the goal of ensuring effective contact and realizing joint bearing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in combination with specific embodiments.

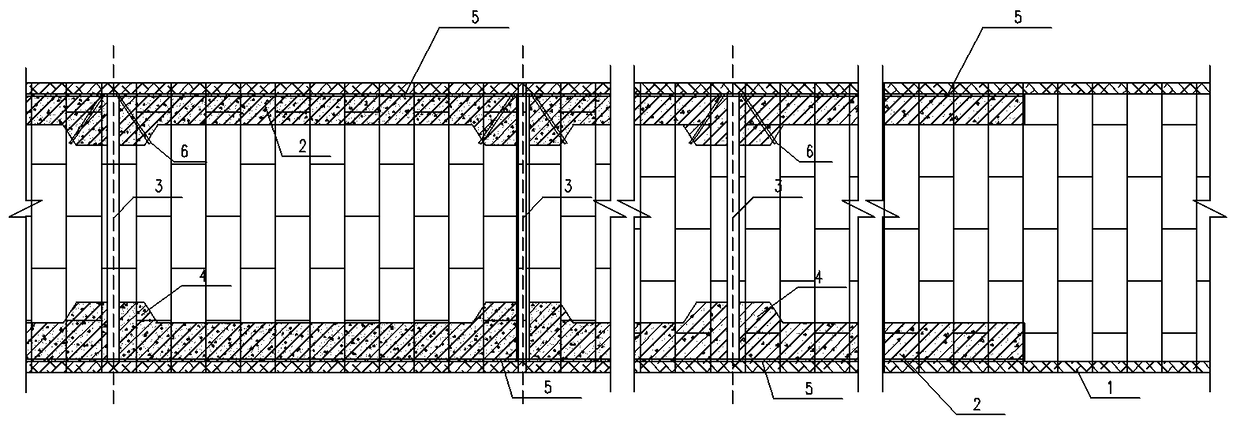

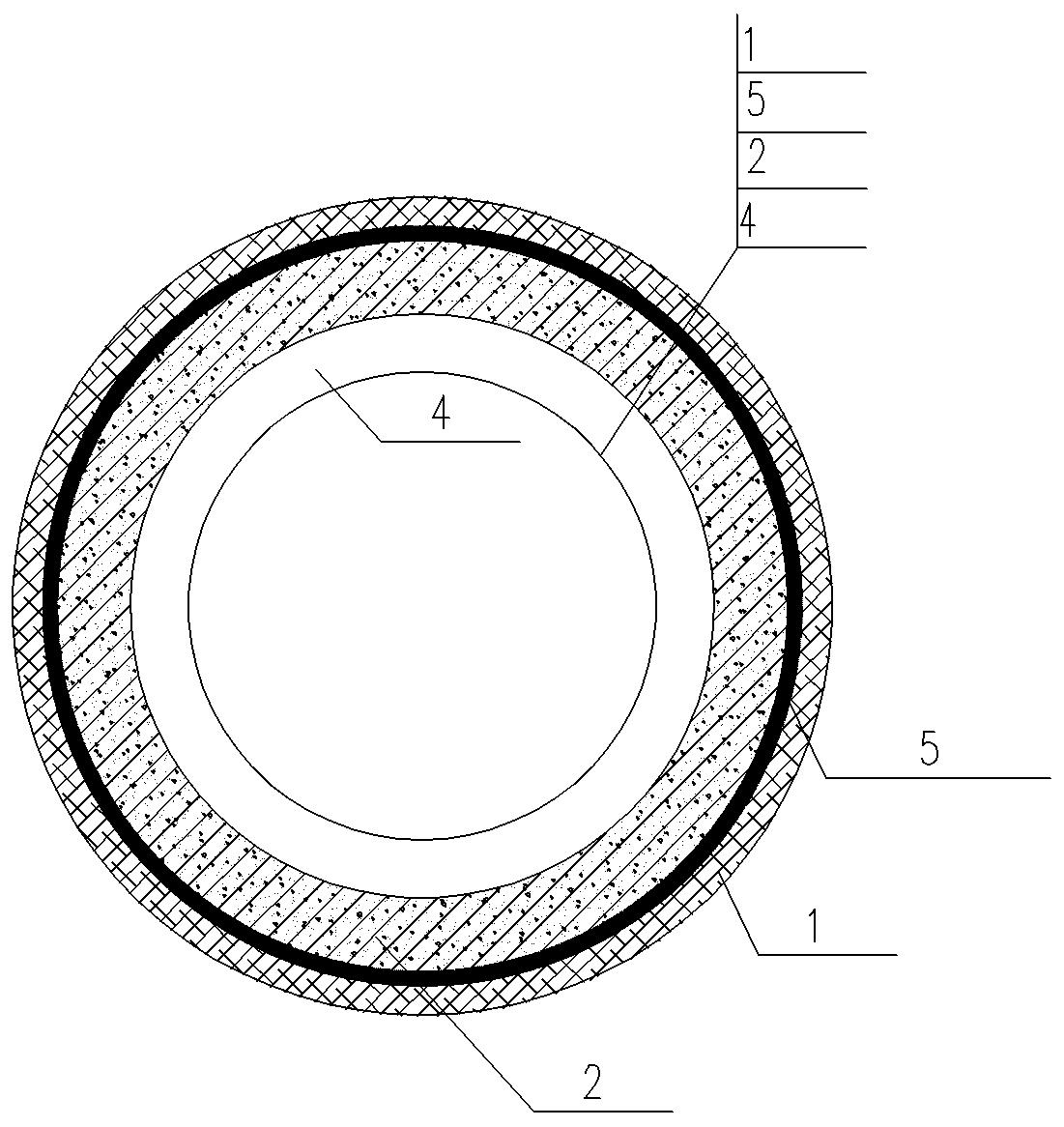

[0026] The present invention relates to the tunnel lining structure in the ground fissure area based on the shield tunneling method. On the secondary lining 2 inside the shield tunneling tunnel 1, a circular special deformation joint 3 is reserved, and the secondary lining 2 at the special deformation joint 3 is The inner circumference protrudes to form an inner convex enlarged head structure 4, and the inner convex enlarged head structure 4 is provided with a pre-embedded grouting pipe 6 at the enlarged head. The secondary lining 2 includes special deformation joints 3 and an inwardly convex enlarged head structure 4, and the secondary lining 2 is poured and constructed after the excavation of the shield tunnel 1 is completed. During the pouring of the secondary lining 2, the internal convex enlarged head structure 4 needs to consider reserving a post-casting belt, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com