Tunnel external convex expanded head structure of mining method in stratum fracture region and construction method thereof

A technology of stratum fracture and construction method, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as unfavorable engineering risks and cost control, enlarging tunnel sections, and unfavorable overall quality control, so as to improve the safety of the surrounding environment and ensure The effect of effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in combination with specific embodiments.

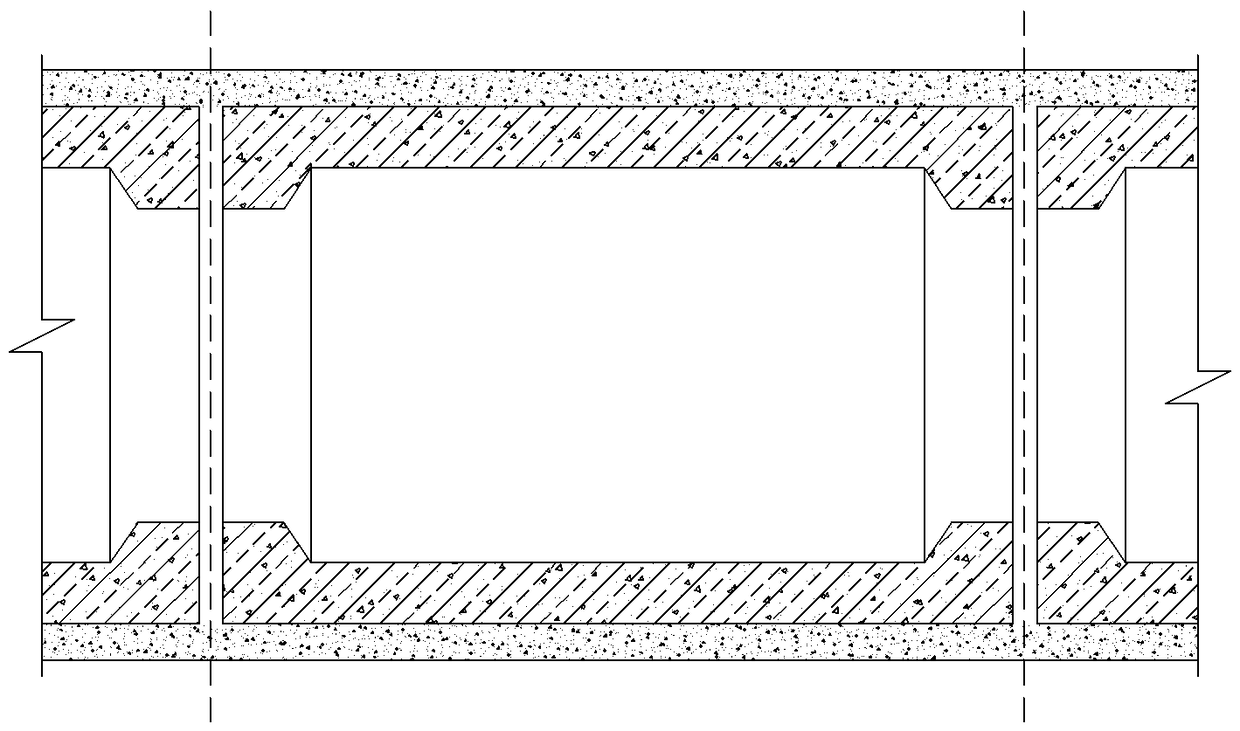

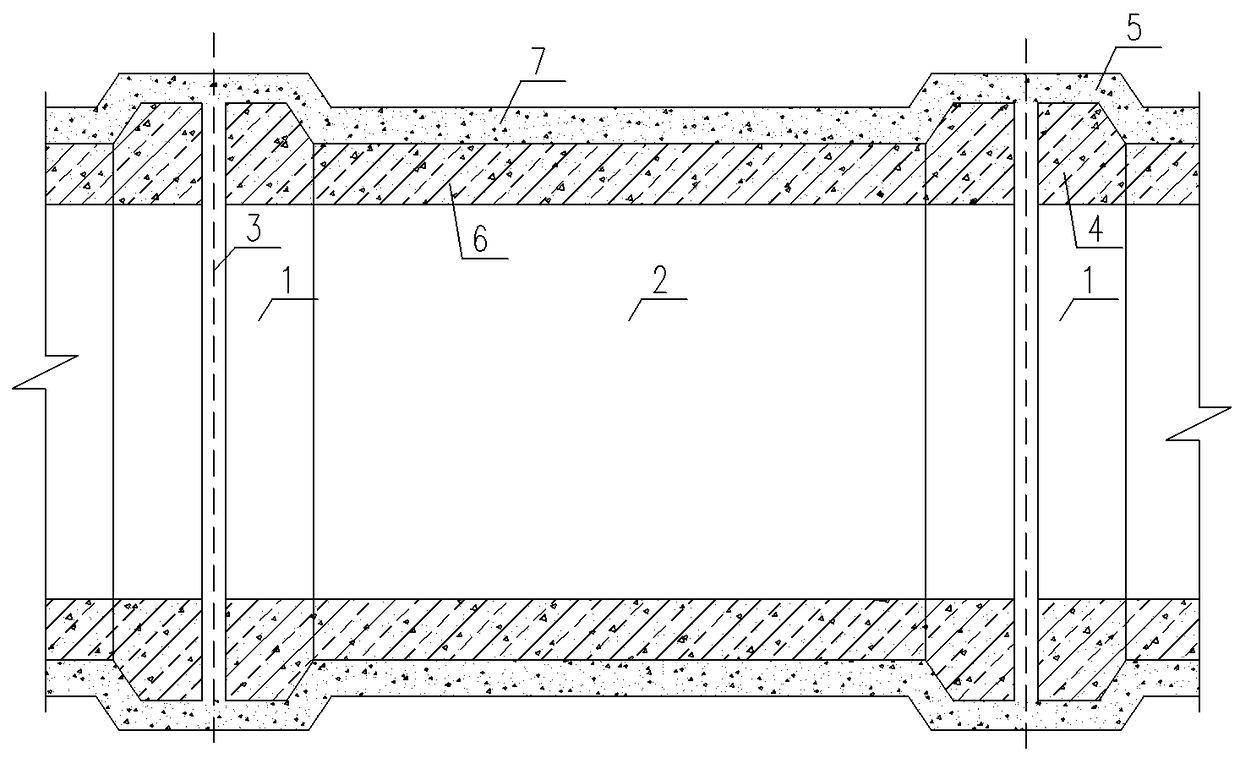

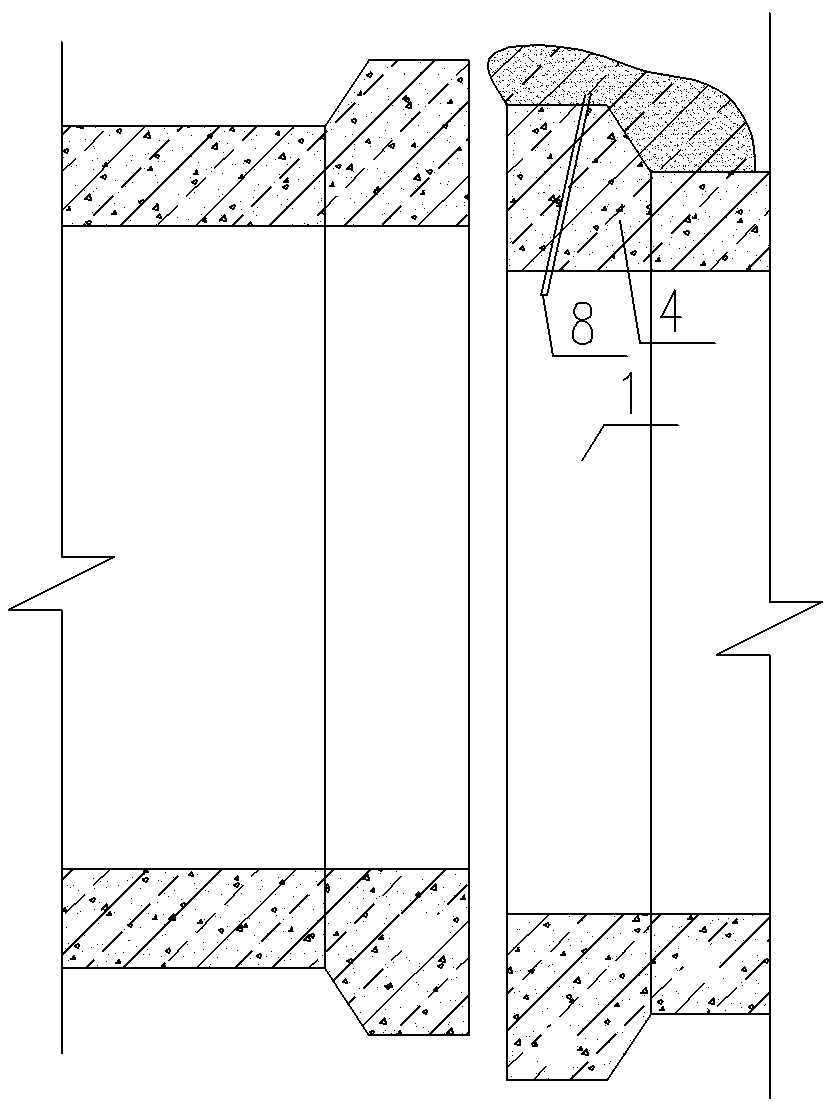

[0034] The present invention relates to an outwardly convex enlarged head structure of a mining method tunnel in a stratum fracture area, which ensures tunnel construction through measures such as large pipe shed or deep hole grouting advance support, CRD method excavation, grid steel frame and internal temporary steel support, etc. Safety, on this basis, the standard mining method tunnel section is expanded and excavated to meet the needs of the enlarged head, and to achieve the maximum deformation or displacement of the stratum, and the effective thickness of the lining structure in the stratum fracture area meets the structural stress requirements.

[0035] The tunnel structure mainly includes the tunnel convex expansion head lining structure composed of two parts: the convex section 1 of the expansion head and the standard section 2; The inner wall of the convex head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com