Double-shield TBM getting stuck prevention method

A technology of double shield and anti-jamming machine, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of double-shield TBM easy-jam machine, etc., so as to improve the passing ability, improve the passing ability, and avoid the cutter head being damaged. card effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

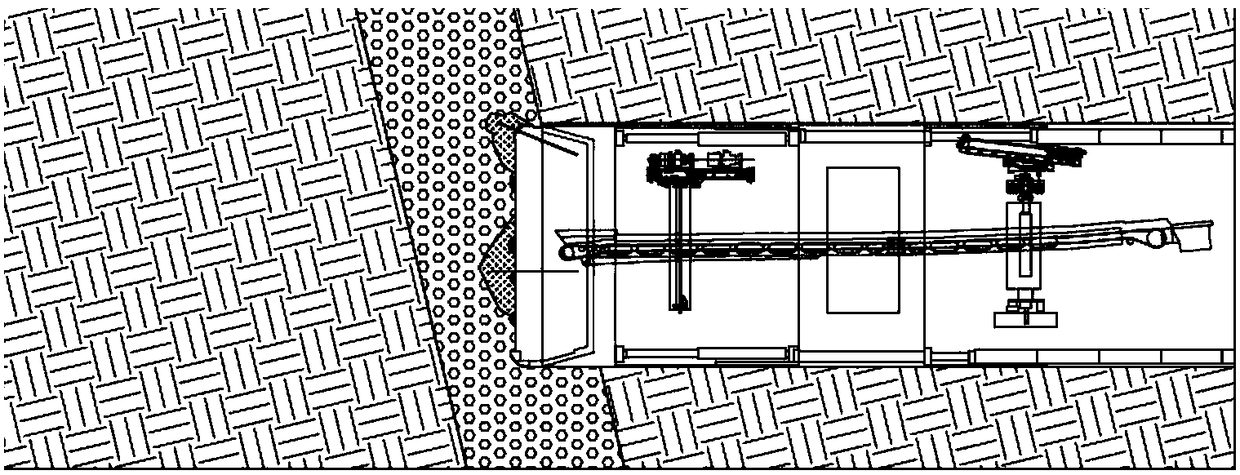

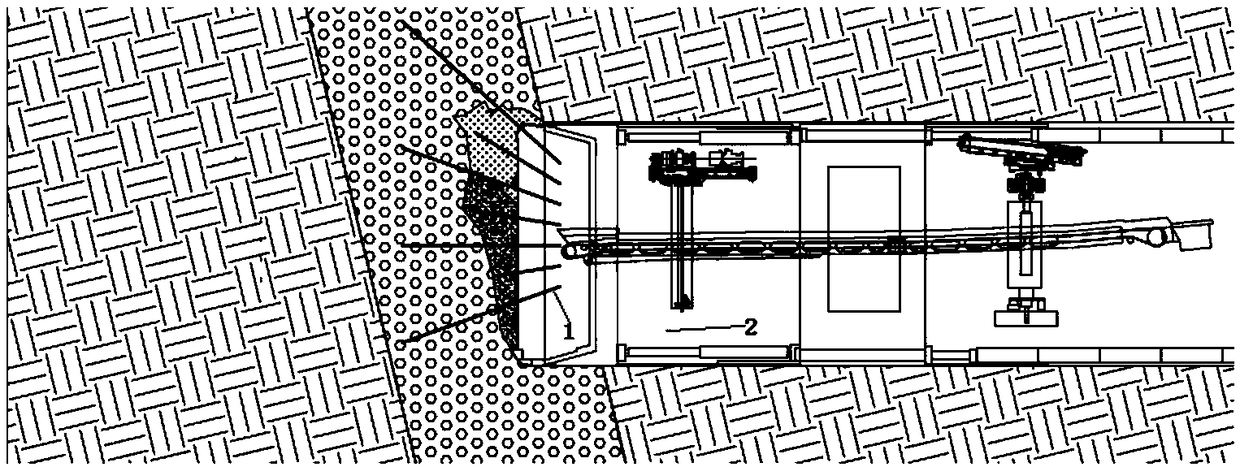

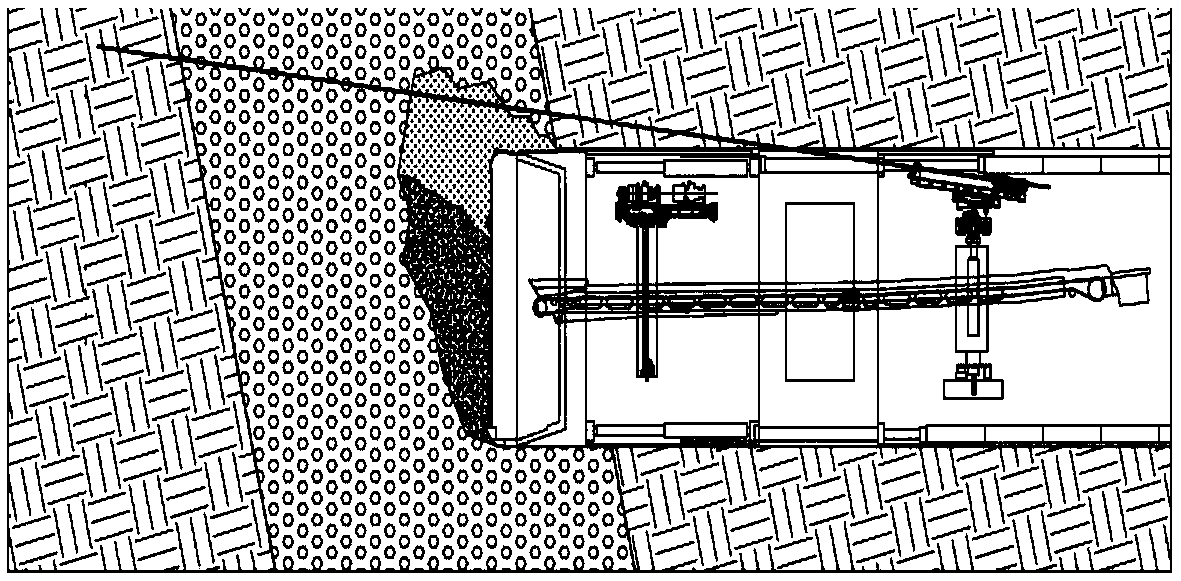

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] 1.1 Double shield TBM risk prevention and control technology

[0040] TBM construction risks are mainly controlled from three aspects: start with geological exploration to avoid geological risks; tap potentials from TBM selection and design to avoid TBM equipment risks; and focus on scientific management to avoid man-made risks.

[0041] 1.1.1 Accurately grasp the geological conditions

[0042] Geological conditions are the most important factor controlling whether the double-shield TBM can be successfully excavated. Detailed and reliable geological and hydrological data are the basic conditions for the success of a TBM project and directly determine the success or failure of the project.

[0043] 1) Fully evaluate the designed geological survey depth before construction. If the preliminary geological survey depth is considered insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com