Single-end-face built-in-type mechanical seal for centrifugal pump

A technology of mechanical seals and centrifugal pumps, which is applied to mechanical equipment, components of pumping devices for elastic fluids, pumps, etc., and can solve problems such as rubber rings are easy to wear and leak, life does not match, and cooling water consumes a large amount of water. , to achieve the effect of improving anti-leakage performance, increasing service life and saving cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

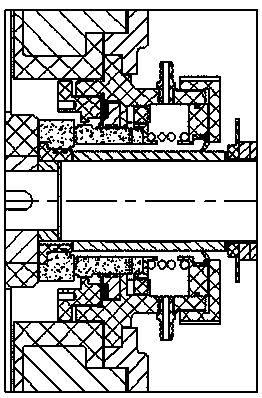

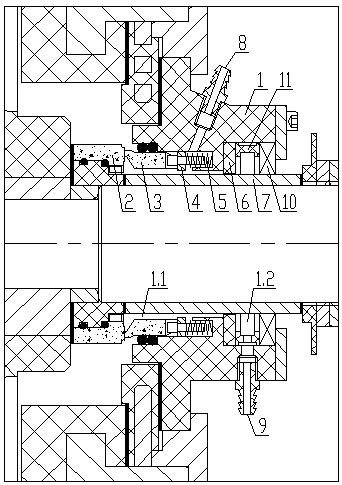

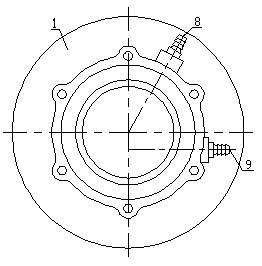

[0023] Such as figure 1 As shown, a single-end built-in mechanical seal for a centrifugal pump includes a seal box 1, a moving ring 2, a static ring 3, a static ring seat 4, a spring 5, a shaft sleeve 7, a cooling water inlet 8, and a cooling water outlet 9. The cooling water sealing ring 10, the mechanical seal is installed on the shaft sleeve 7, and the shaft sleeve 7 is sleeved on the main shaft. The inner wall of the moving ring 2 is provided with a concave step to cooperate with the convex step on the shaft sleeve 7 to limit the position , the static ring 3 is in contact with the end face of the dynamic ring 2 for sealing, the sealing box 1 is fixedly connected to the pump casing of the centrifugal pump for sealing, the spring 5 is installed in the sealing box 1 and connected with the static ring 3, the static ring 3 is set at the front end of the sealing box 1, and the static ring 3 is in contact with the sealing box 1 for sealing, the top contact surface of the static r...

Embodiment 2

[0025] Embodiment 2, with reference to Embodiment 1, another cooling water outlet 9.1 is provided at the high pressure zone 1.1.

Embodiment 3

[0026] Embodiment 3, referring to Embodiment 1, the sealing box 1 and the retaining ring 6 are integrally formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com