Engine reversing transmission box for agricultural equipment peanut harvester

A peanut harvester, reversing transmission technology, applied in transmission parts, mechanical equipment, belts/chains/gears, etc., can solve the problems of difficulty in the arrangement of the whole machine, improve the heat dissipation effect, and prolong the continuous use time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

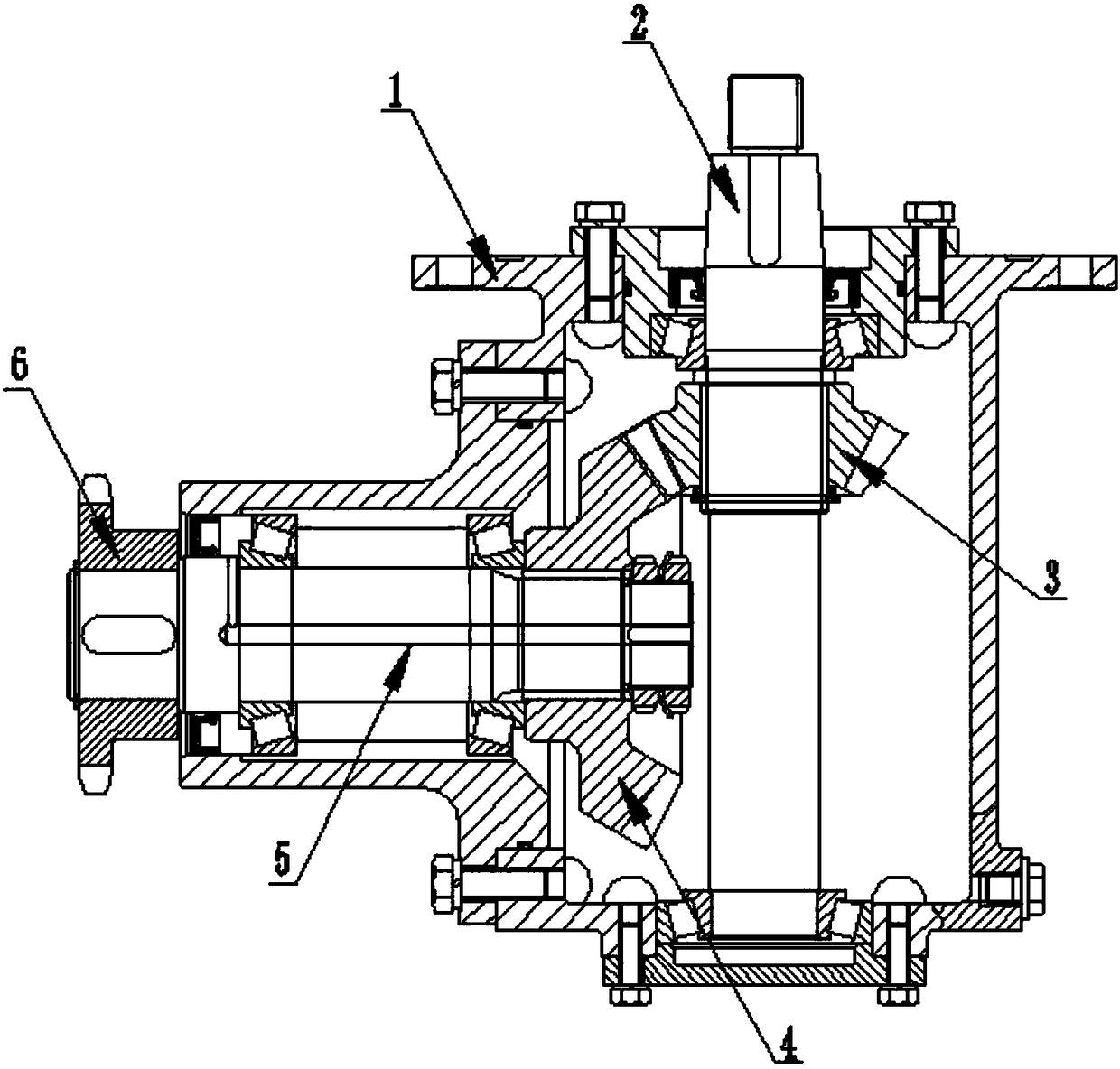

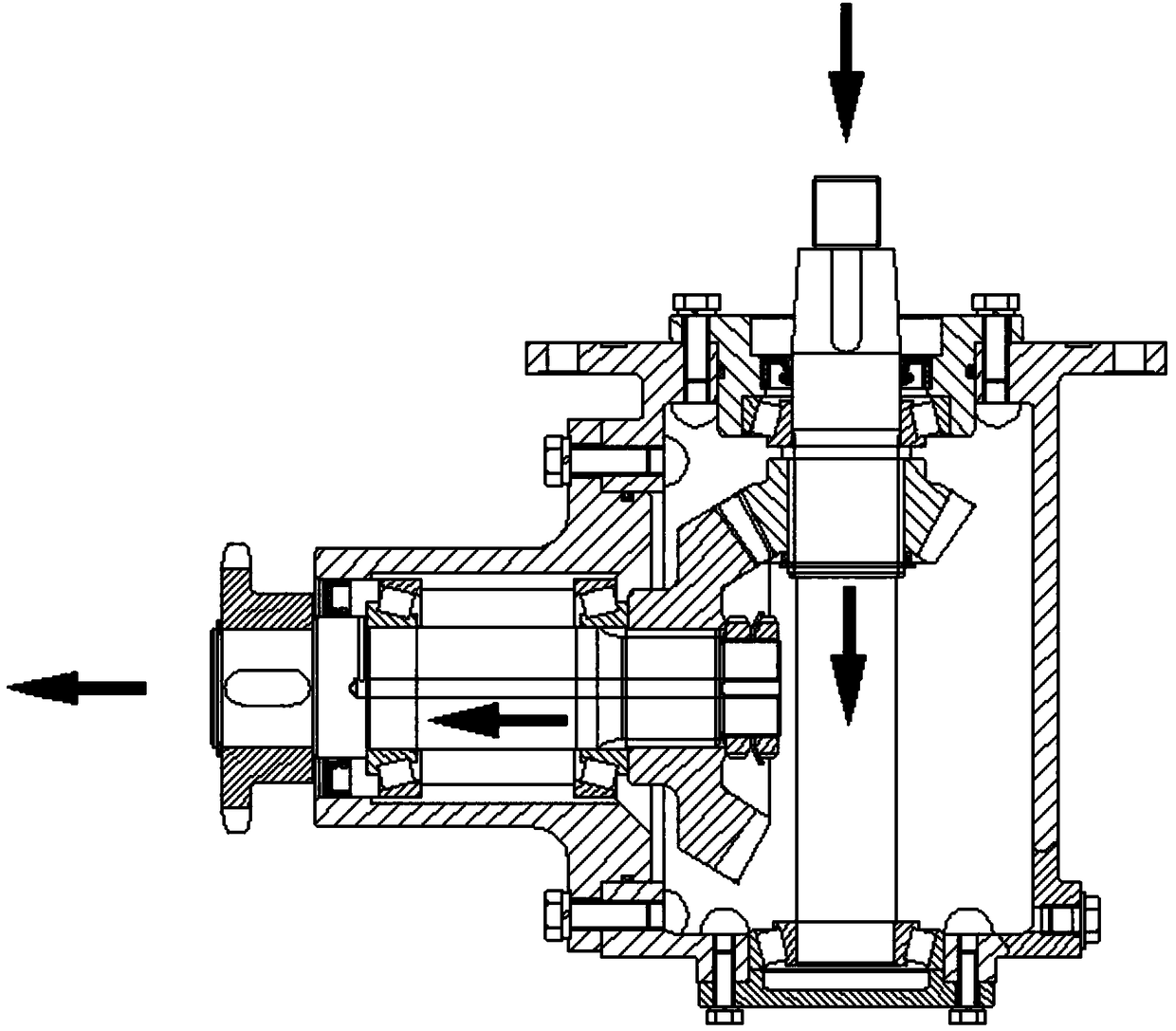

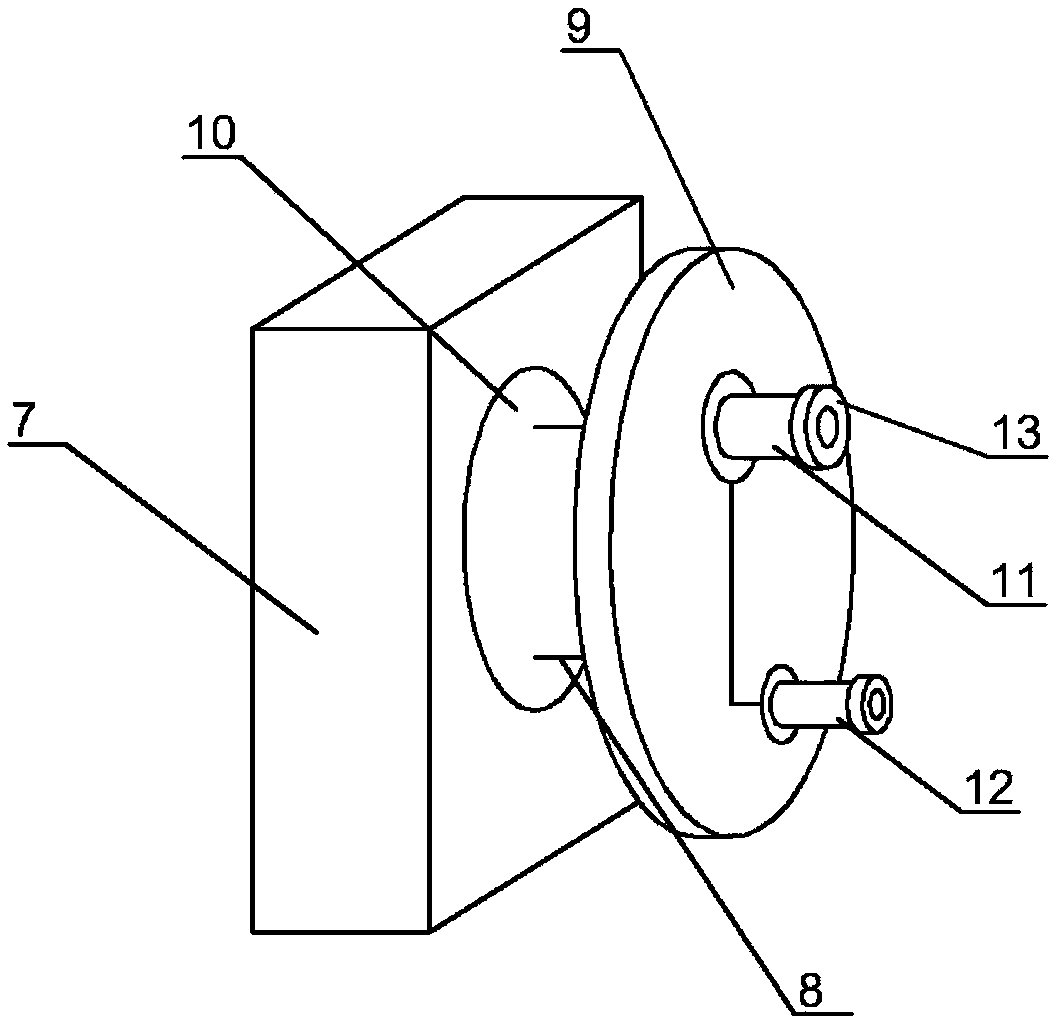

[0016] The engine reversing transmission box for agricultural equipment peanut harvester includes a transmission box main body 1, the main input shaft 2 is placed in the transmission box 1 longitudinally, and the upper and lower ends of the main input shaft 2 are rotatably fixed. The middle part of the shaft 2 is provided with an active arc gear 3. When the main input shaft 3 drives the active arc gear 4 to rotate, the active arc gear 4 engages the passive arc gear 5 to drive the rotation, and the passive arc gear 5 finally drives the output sprocket 6 to rotate after driving the output shaft.

[0017] Heat dissipation ribs are added on the exterior of the transmission box main body 1 to increase the heat dissipation area for auxiliary heat dissipation.

[0018] The upper cover of the transmission box main body 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com