Improved streetlamp device

An improved street lamp technology, applied to lighting devices, lighting auxiliary devices, lighting device components, etc., can solve the problems of increased mains power consumption, inability to adjust, damage, etc., and achieve increased service life, convenient operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

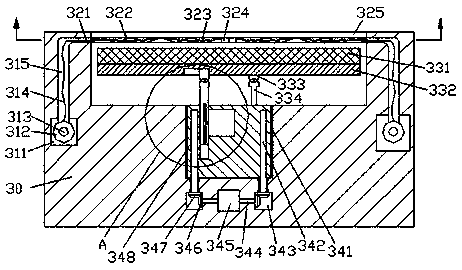

[0015] Combine below Figure 1-4 The present invention will be described in detail.

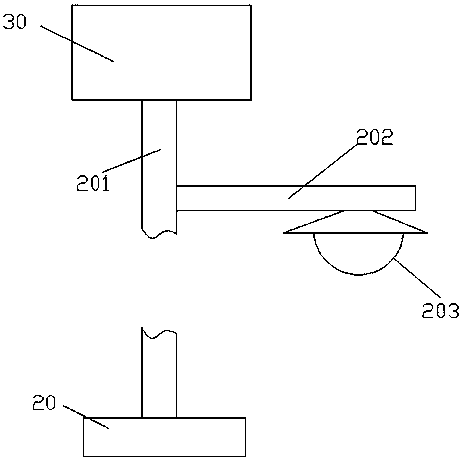

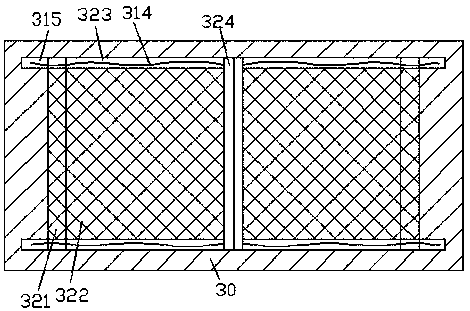

[0016] refer to Figure 1-4 , an improved street light device according to an embodiment of the present invention, comprising a fixing base 20 and a frame 30 fixed above the fixing base 20 through a lamp post 201, and the right side end of the lamp post 201 is extended to the right There is a lamp arm 202, the bottom end of the lamp arm 202 is provided with an LED bulb 203, the top end of the frame 30 is provided with a placement cavity 325, and the upper side of the inner wall of the front and rear sides of the placement cavity 325 is correspondingly provided with a second A chute 323, the inner walls of the left and right sides of the placement cavity 325 are correspondingly provided with telescopic grooves 321 intercommunicating with the first chute 323, and the outer sides of the telescopic groove 321 are correspondingly provided with through grooves 315 front and rear, and the telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com