A monitoring system and method for micro-displacement deformation based on tension sensor

A tension sensor and deformation monitoring technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of inability to meet practical applications, satellite signal occlusion, and high monitoring costs, and achieve the effects of high reuse rate, simple maintenance, and low burying costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

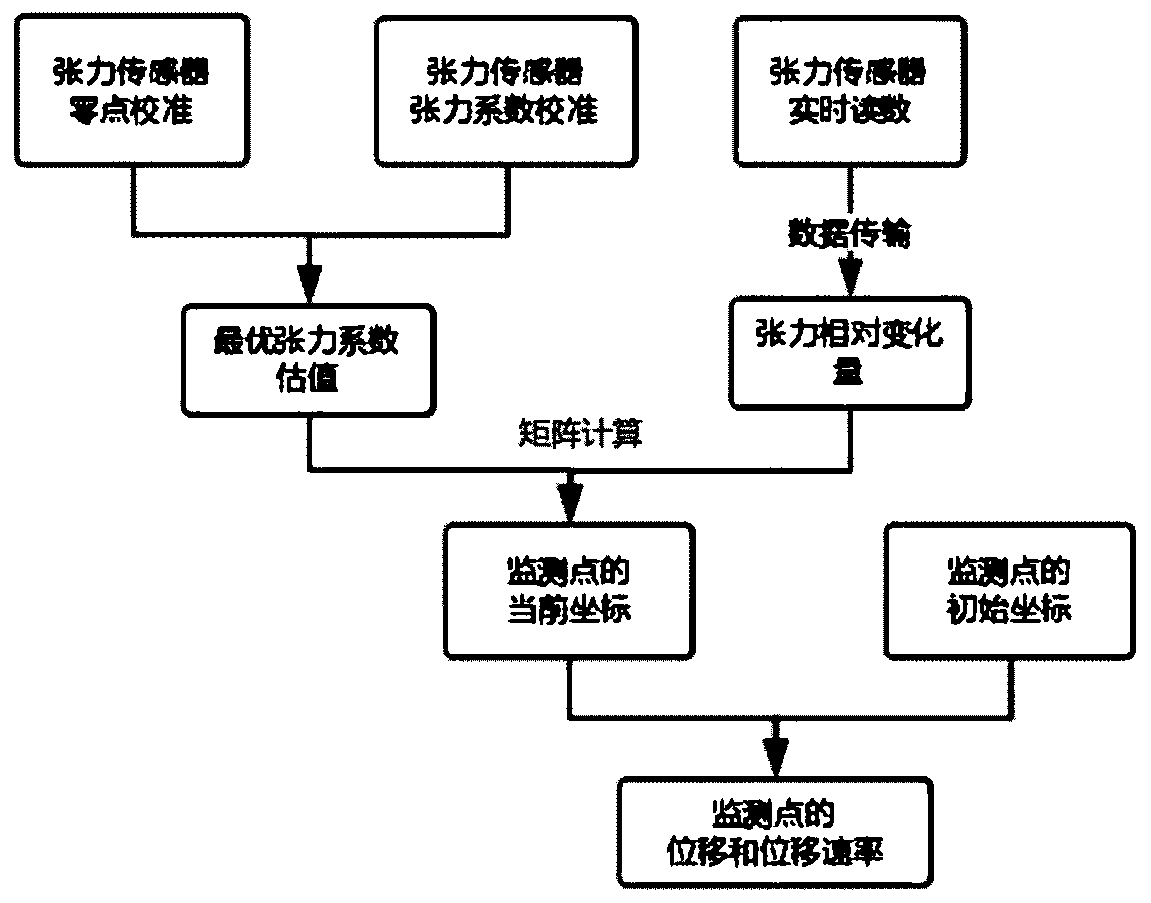

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

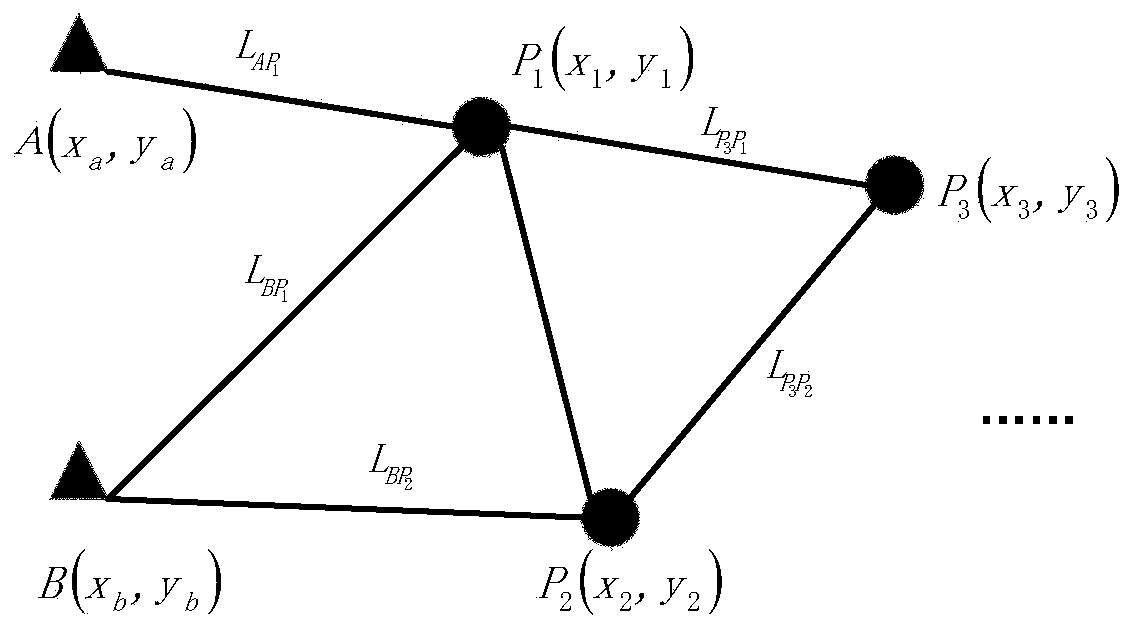

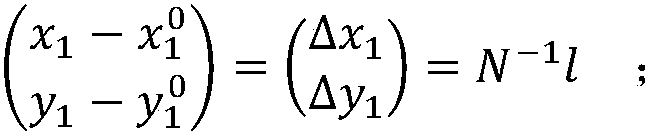

[0030] A tension sensor-based micro-displacement deformation monitoring system provided by the present invention includes a tension sensor, a spring, a steel wire, a communication device, and a power supply device; taking two monitoring points as an example, one of the monitoring points is directly connected to the spring, and the other A tension sensor is installed at the monitoring point. The spring and the tension sensor are connected by a steel wire and the steel wire is tightened within the range of the sensor. After the power supply device supplies power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com