Automatic deep-groove-ball-bearing wear life testing machine

A technology for deep groove ball bearings and wear life, which is applied in the direction of mechanical bearing testing, wear resistance testing, and testing of mechanical components. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

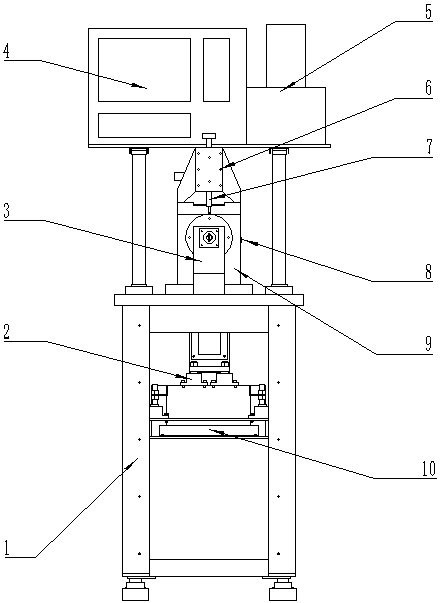

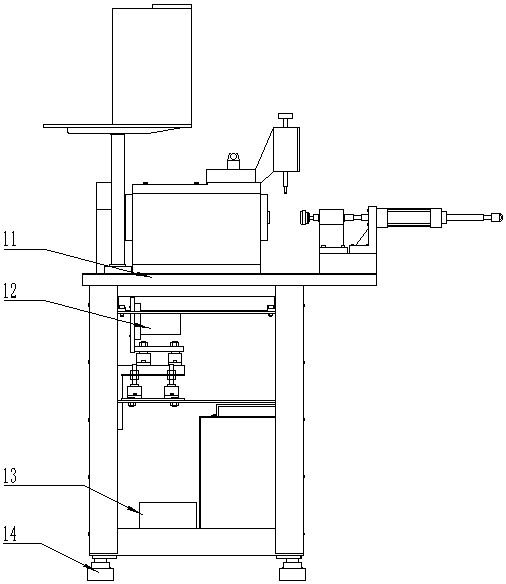

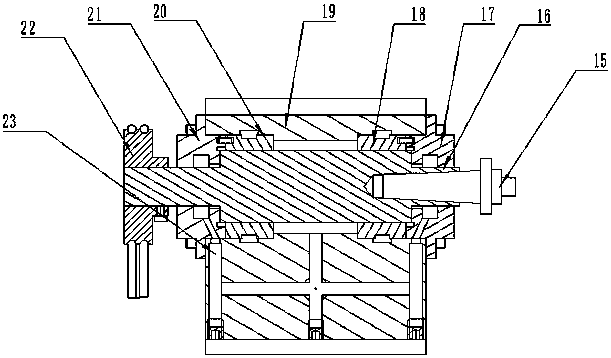

[0018] See attached figure 1 And attached figure 2 , an automatic deep groove ball bearing wear life testing machine of this embodiment, including a frame 1, a motor base 2, an axial loading device 3, an industrial computer 4, a charge amplifier (bottom) and a sound box (top) 5, an acceleration Sensor locking mechanism 6, sleeve and vibration transmission rod 7, oil lubrication inlet 8, drive system 9, electrical installation board 10, workbench 11, motor 12, oil tank 13, support feet 14, wherein the axial load The device 3 is placed on the upper side and the rightmost side of the workbench 11, aligned with the main shaft 16; the motor seat 2 is on the lower side of the workbench 11; the industrial computer 4, the charge amplifier and the sound box 5 are placed on the workbench 11 on the upper supporting plate; the industrial computer 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com