Nickel foam surface defect image segmentation method

An image segmentation, surface image technology, applied in the field of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

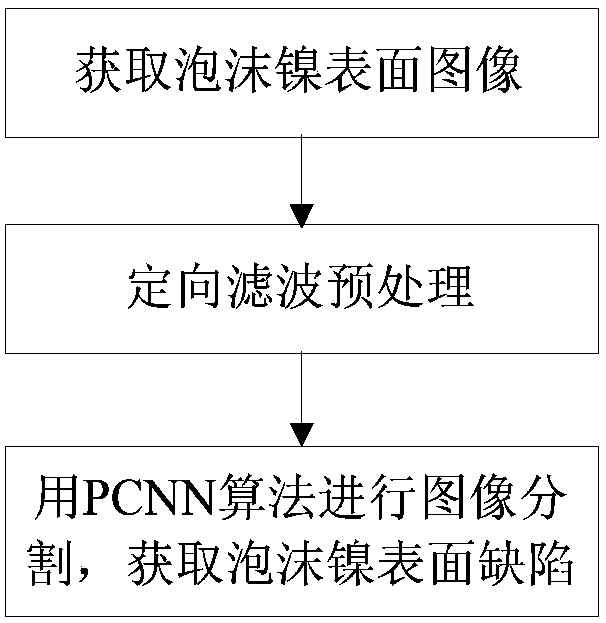

[0011] Taking nickel foam with nickel skin defects on the surface as the detection object, the surface image of nickel foam is obtained. The image resolution is 1080×720, which can meet the detection requirements. Combined with figure 1 The specific steps of the method are as follows:

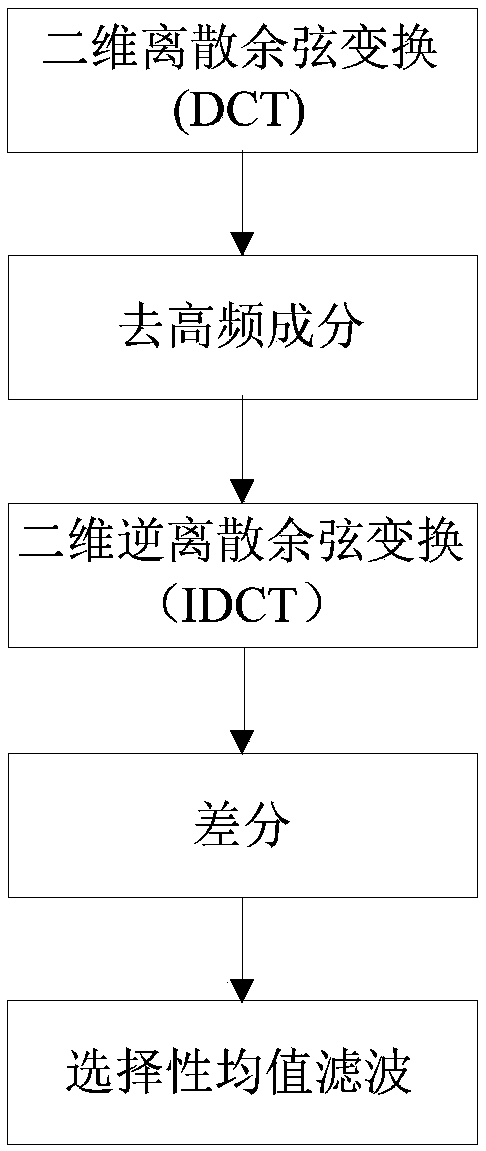

[0012] Step 1: Acquire the surface image of nickel foam, and preprocess the surface image with directional filtering, combined with figure 2 , the preprocessing process is as follows:

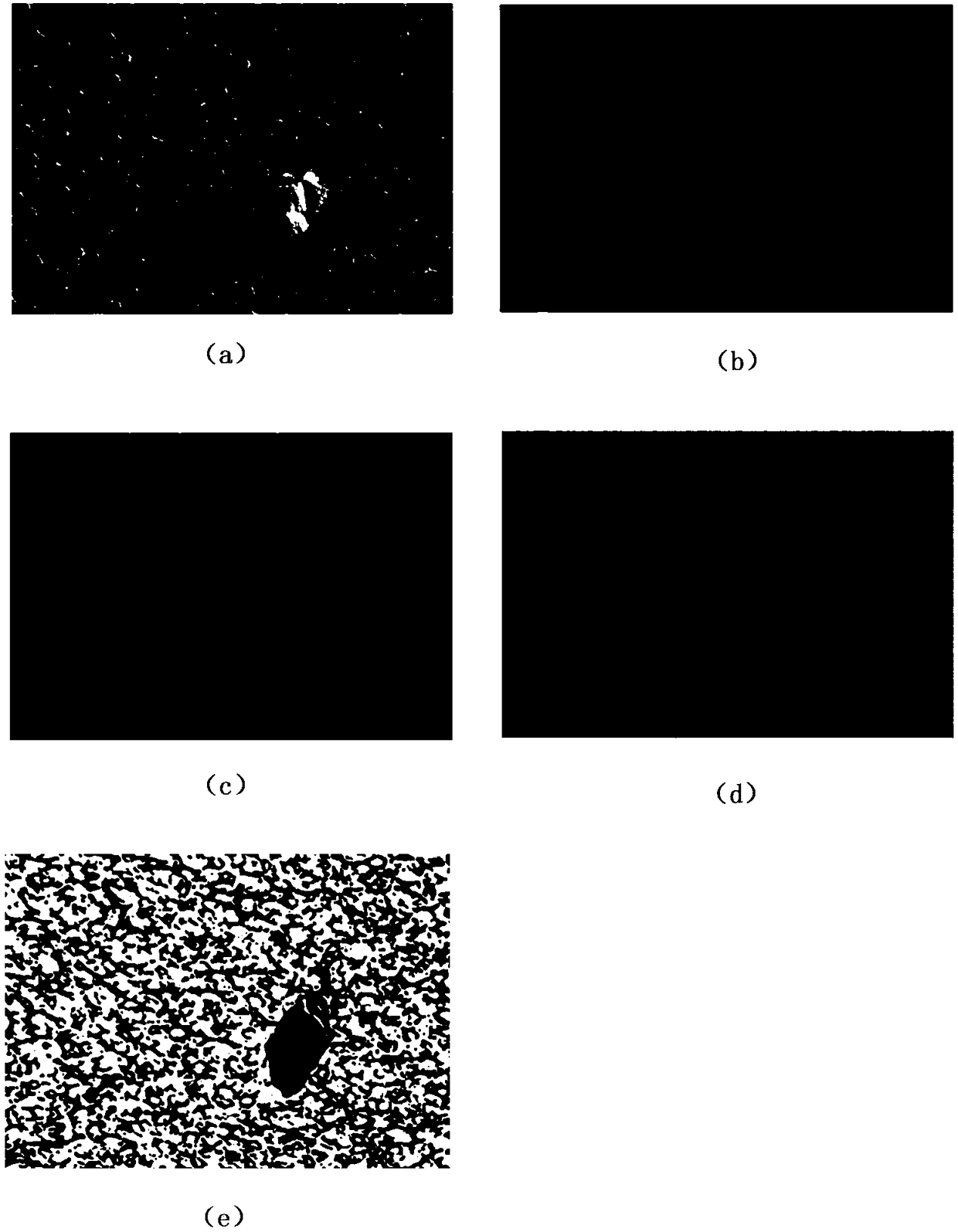

[0013] 1) The surface image I(i,j) of the obtained nickel foam, such as image 3 As shown in (a), the surface defect of the visible image is fused with the background, and it is difficult to directly extract the defect. Two-dimensional discrete cosine transform (DCT) is performed on the image:

[0014]

[0015] In the formula,

[0016]

[0017] Convert the image from the spatial domain to the frequency domain, and the image is divided into low-frequency regions and high-frequency regions;

[0018] 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com