High-safety air-type busway

A high-safety, busway technology, applied in the direction of fully enclosed busbar devices, can solve the problems of reducing work efficiency, improving scrap rate, time-consuming and laborious, etc., achieving compact structure, beautiful appearance, and increasing the effect of heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

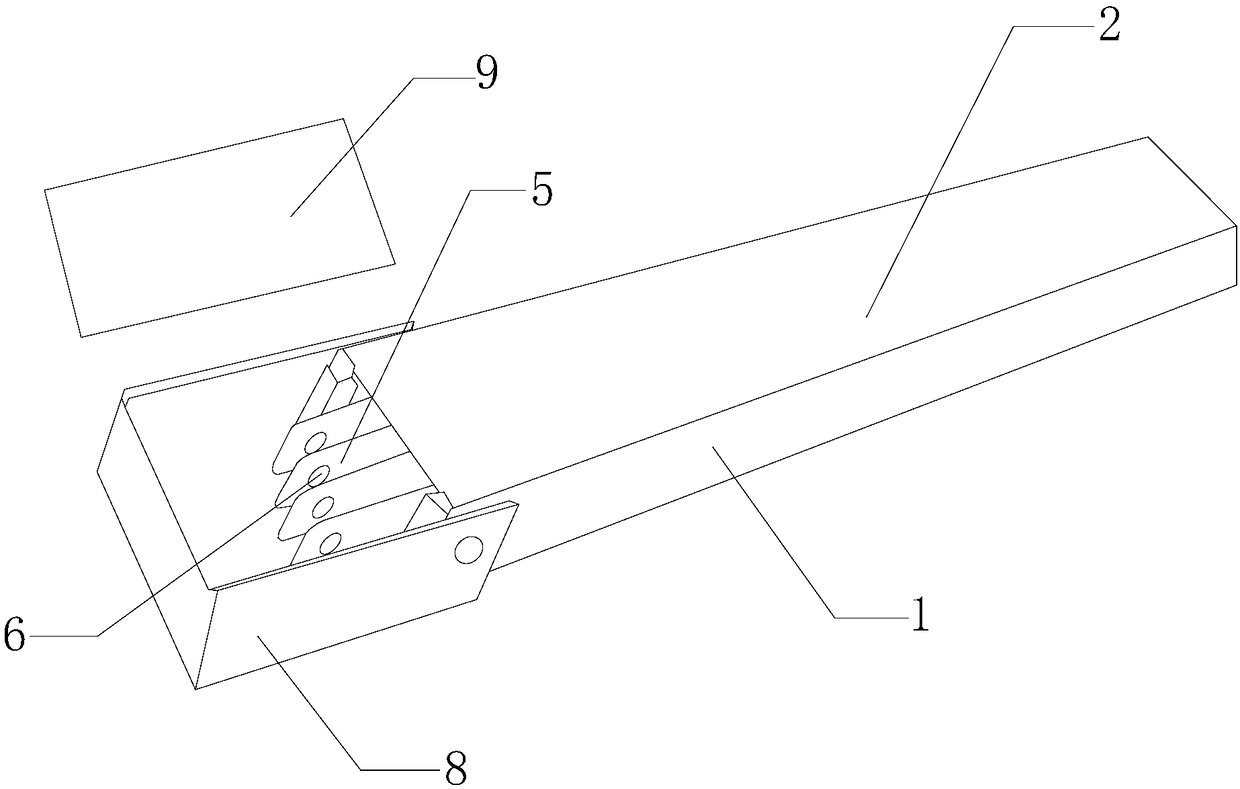

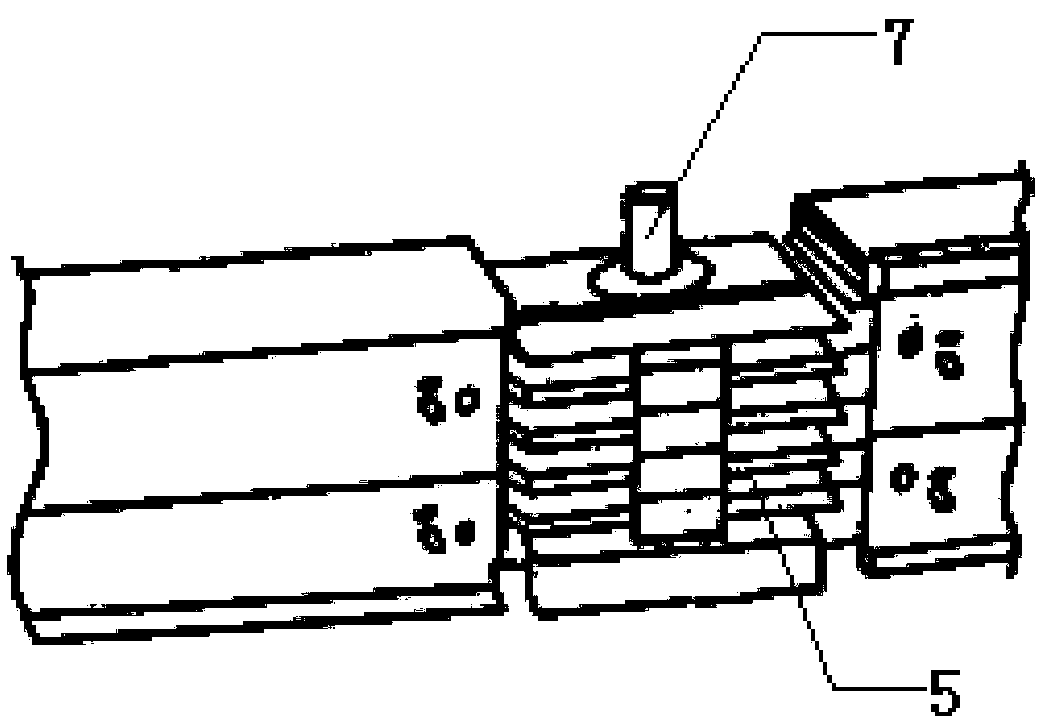

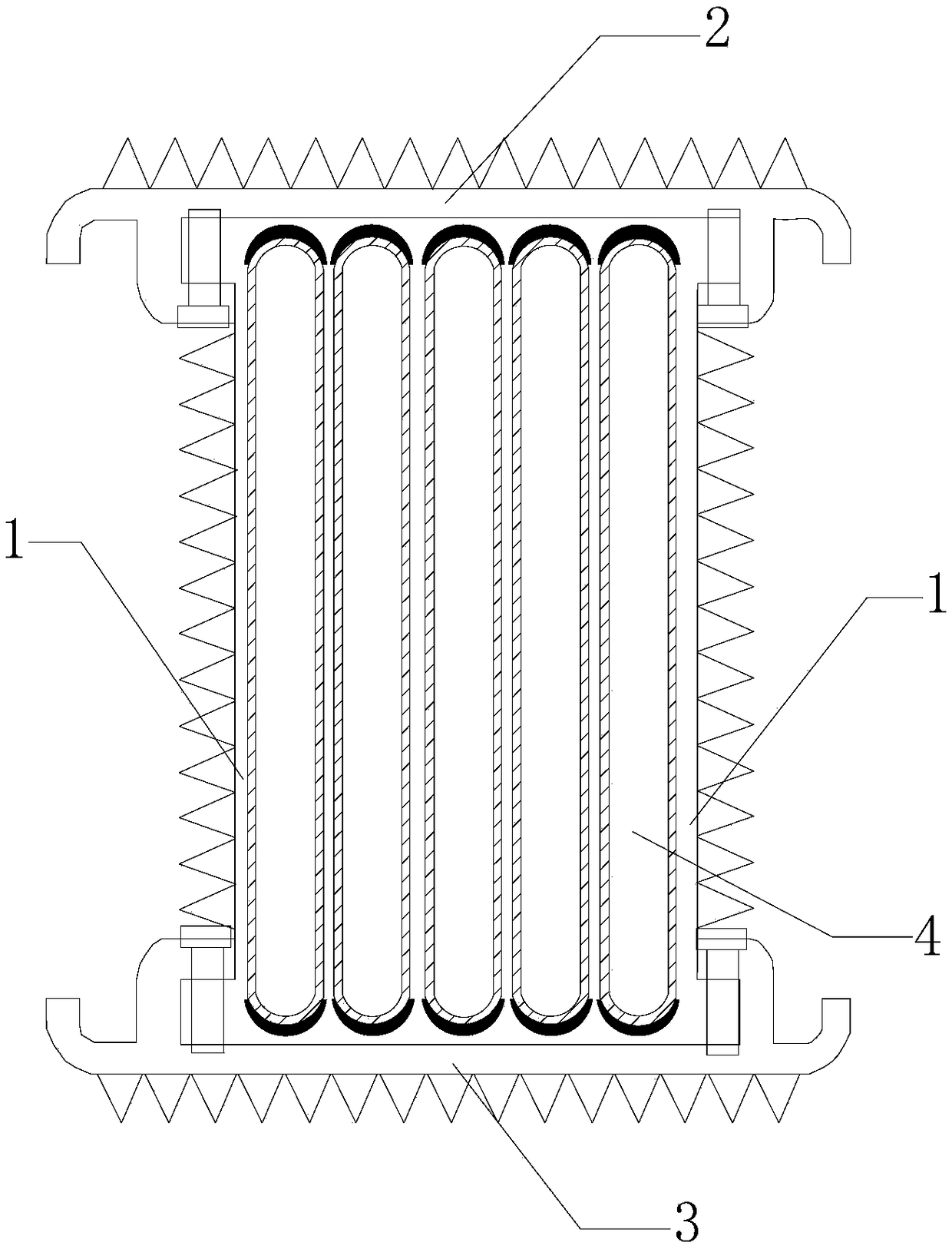

[0025] This embodiment provides a high-safety air-type busway, including the busway shell, which is made of cold-rolled thin steel in one cold rolling, and the busway shell is closed by side plates 1 and cover plates 2 on the left and right sides and a closed bottom plate 3, the inner surfaces of the closed side plates 1, the cover plate 2 and the closed bottom plate 3 on the left and right sides are corrugated corrugated groove structures, and the cover plate 2 is provided with four corrugated grooves or five corrugated grooves, and the left and right sides The closed side plate 1, the cover plate 2 and the closed bottom plate 3 constitute the closed space of the bus duct, and the conductive bus bar 4 is vertically built in the closed space of the bus duct, and the conductive bus bar 4 is wrapped with an insulating medium and then stuck in the closed space of the bus duct In the corresponding corrugated groove structure, one end of the conductive busbar 4 extends out of the bu...

Embodiment 2

[0032] This embodiment provides a high-safety air-type busway, including the busway shell, which is made of cold-rolled thin steel in one cold rolling, and the busway shell is closed by side plates 1 and cover plates 2 on the left and right sides and a closed bottom plate 3, the inner surfaces of the closed side plates 1, the cover plate 2 and the closed bottom plate 3 on the left and right sides are corrugated corrugated groove structures, and the cover plate 2 is provided with four corrugated grooves or five corrugated grooves, and the left and right sides The closed side plate 1, the cover plate 2 and the closed bottom plate 3 constitute the closed space of the bus duct, and the conductive bus bar 4 is vertically built in the closed space of the bus duct, and the conductive bus bar 4 is wrapped with an insulating medium and then stuck in the closed space of the bus duct In the corresponding corrugated groove structure, one end of the conductive busbar 4 extends out of the bu...

Embodiment 3

[0039] This embodiment provides a high-safety air-type busway, including the busway shell, which is made of cold-rolled thin steel in one cold rolling, and the busway shell is closed by side plates 1 and cover plates 2 on the left and right sides and a closed bottom plate 3, the inner surfaces of the closed side plates 1, the cover plate 2 and the closed bottom plate 3 on the left and right sides are corrugated corrugated groove structures, and the cover plate 2 is provided with four corrugated grooves or five corrugated grooves, and the left and right sides The closed side plate 1, the cover plate 2 and the closed bottom plate 3 constitute the closed space of the bus duct, and the conductive bus bar 4 is vertically built in the closed space of the bus duct, and the conductive bus bar 4 is wrapped with an insulating medium and then stuck in the closed space of the bus duct In the corresponding corrugated groove structure, one end of the conductive busbar 4 extends out of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com