Pre-locating shake-off layering harvester

A technology of pre-positioning and picking machines, which is applied in the fields of picking machines, harvesters, agricultural machinery and implements, can solve the problems of difficulty and low efficiency in picking winter jujubes, and achieves the goal of improving the shake-off rate, ensuring high efficiency and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

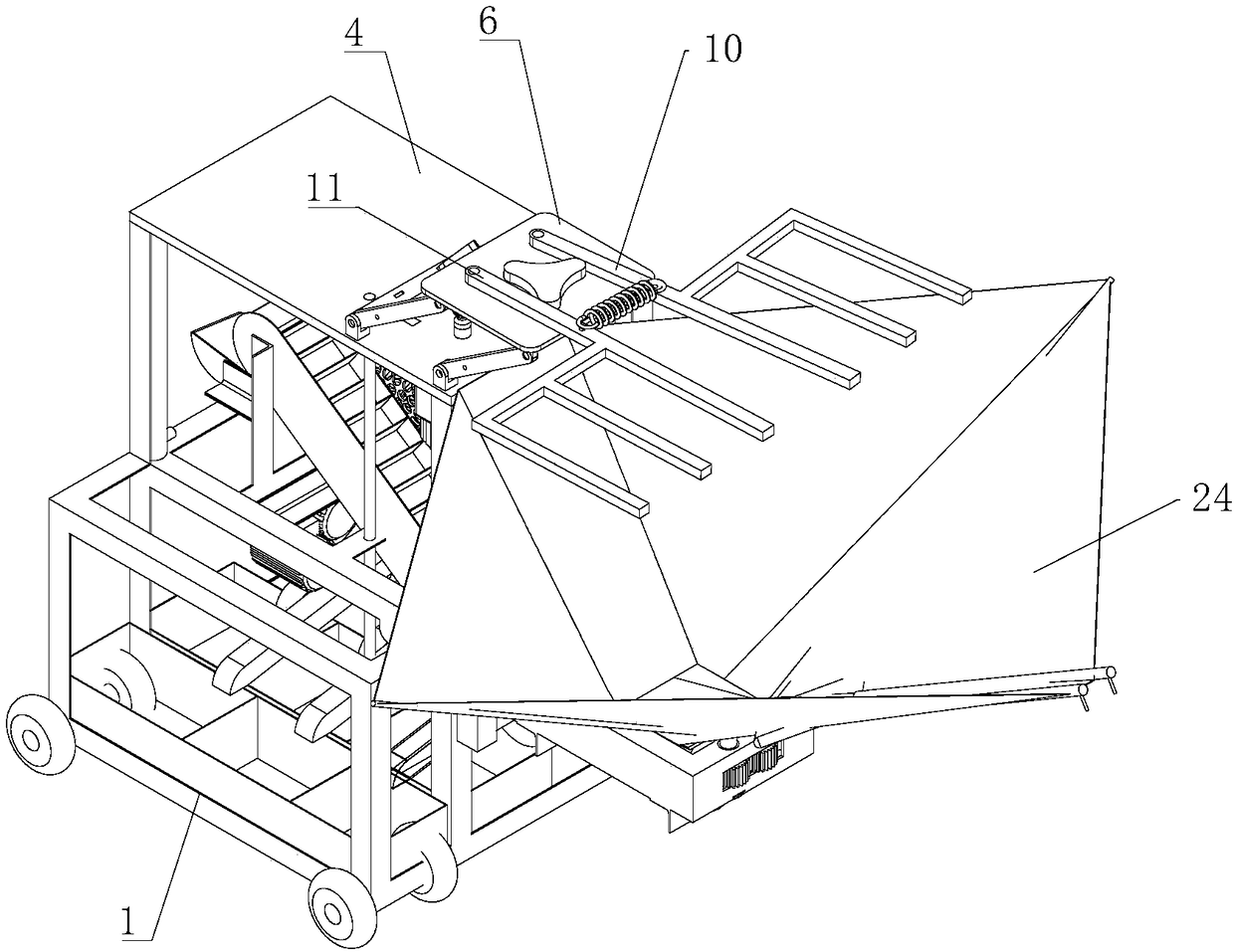

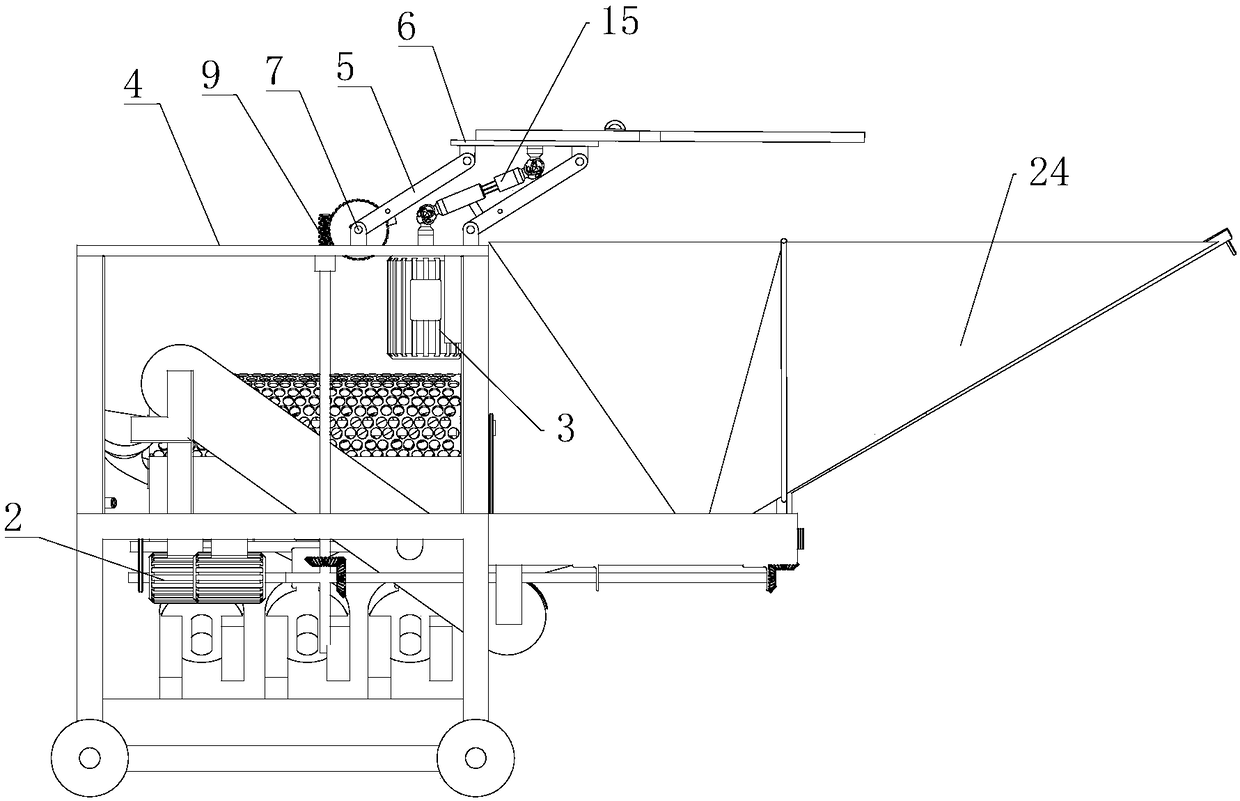

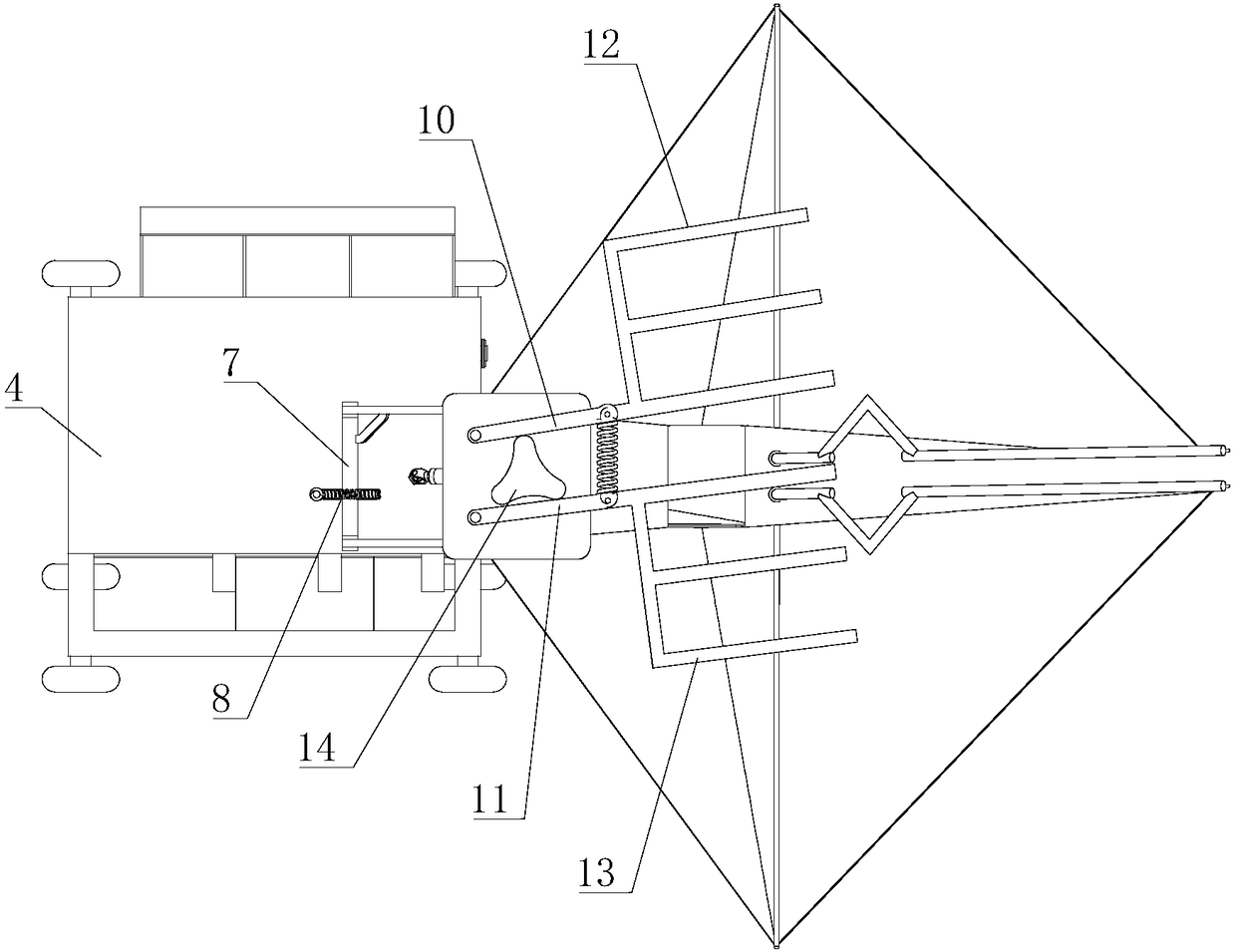

[0051] Such as figure 1 , figure 2 with image 3 As shown, it is an embodiment of the pre-positioning vibrating and layered picking machine of the present invention, which is mainly used for picking fruits on fruit trees, and can ensure that the fruits are not damaged under the premise of improving the picking rate.

[0052] This embodiment firstly includes a frame on which a plurality of mechanisms are arranged, mainly including a parallel four-bar forward extension mechanism, a wide-tooth vibrating mechanism, a layered pre-positioning mechanism, a distance measuring mechanism, a fan-surface unfolding and collecting mechanism, and a roller shaft. The baffle conveying mechanism, the threaded roller grading mechanism, and a plurality of motors for power supply mainly include the first motor 2 and the second motor 3, and the structure of each mechanism will be described in detail below.

[0053] Such as Figure 5 As shown, the parallel four-bar forward extension mechanism in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com