Device capable of fully realizing solid-liquid separation of medical waste

A technology of solid-liquid separation and medical waste, applied in the direction of solid waste removal, waste disinfection or sterilization methods, chemistry, etc., can solve the problems affecting the health and mood of staff, the harm of patients and medical staff, and the residual waste liquid of medical waste To achieve the effect of convenient classification and processing, improving filtration efficiency and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

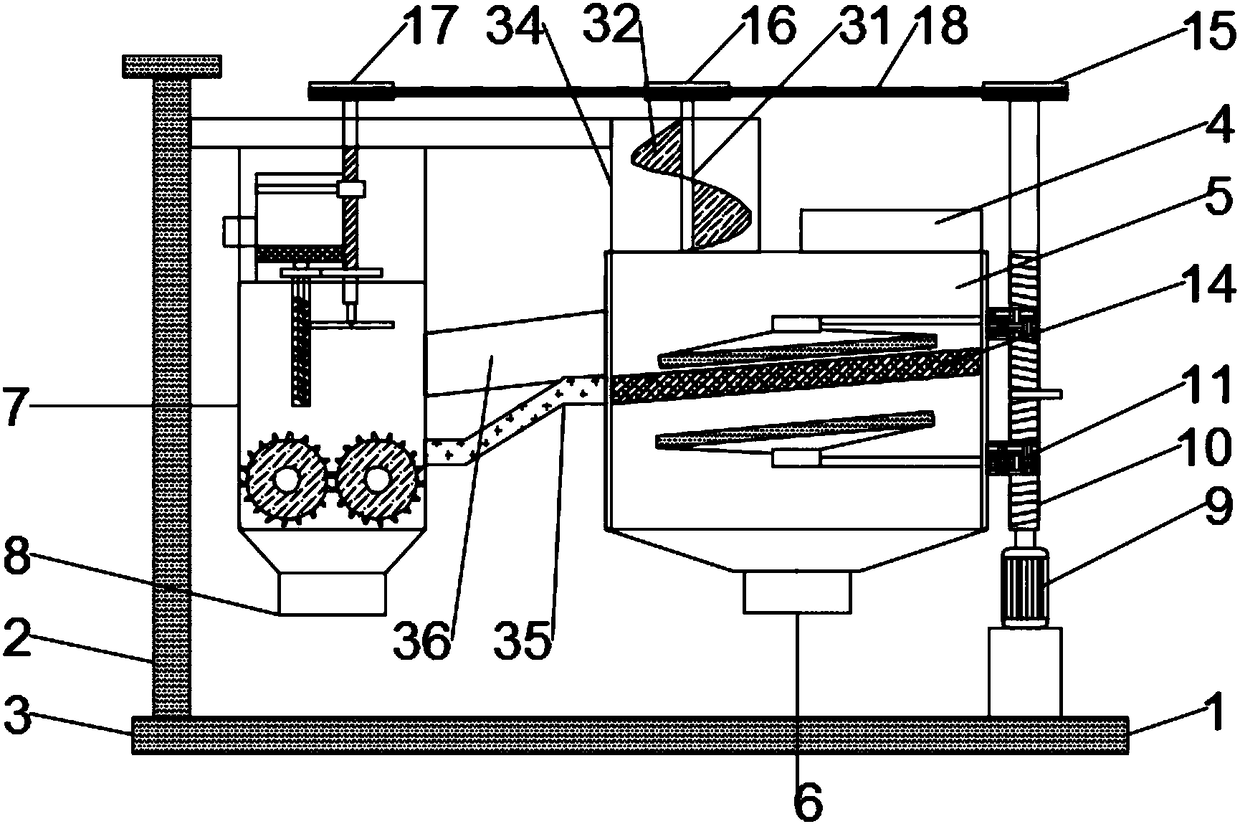

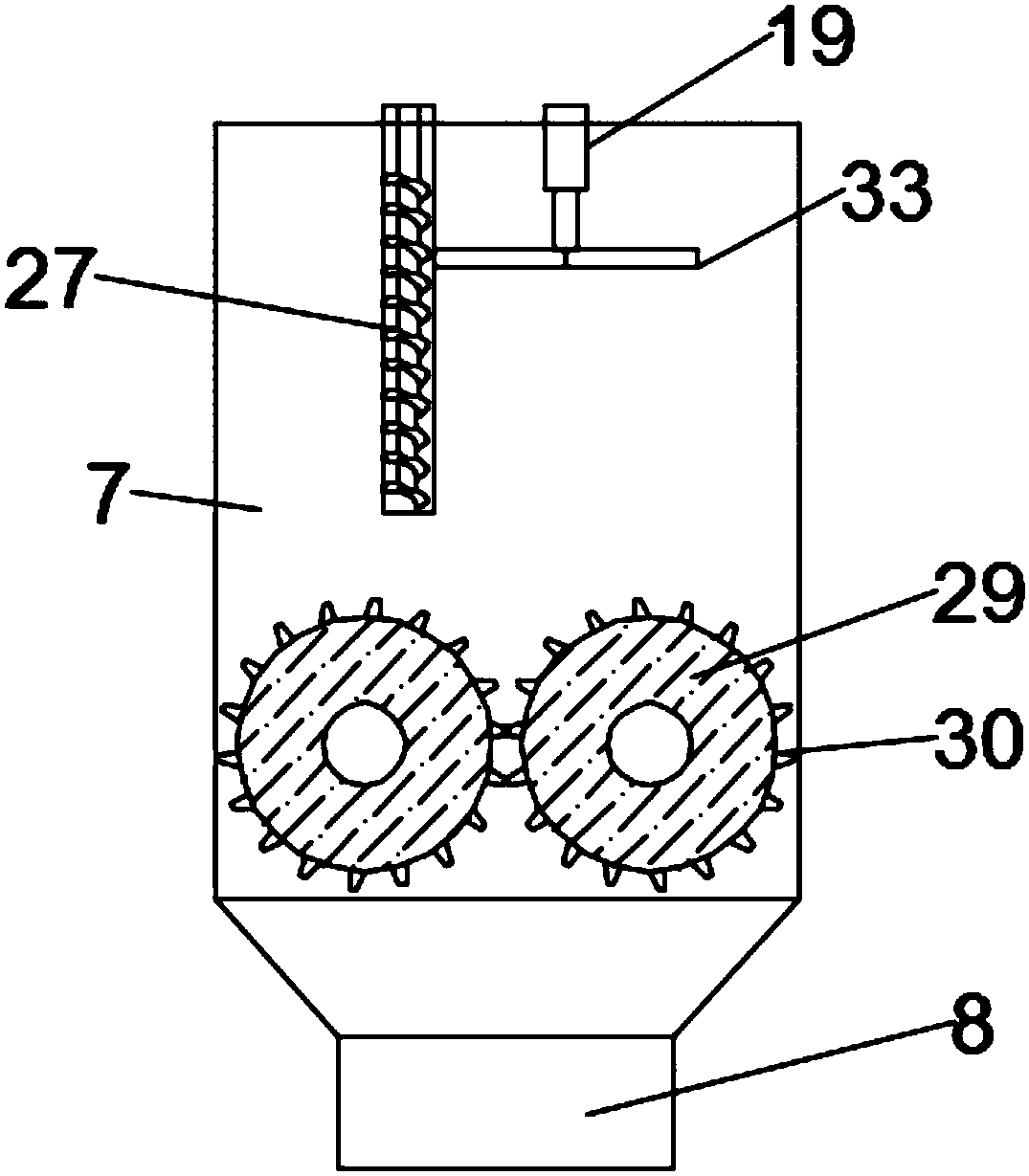

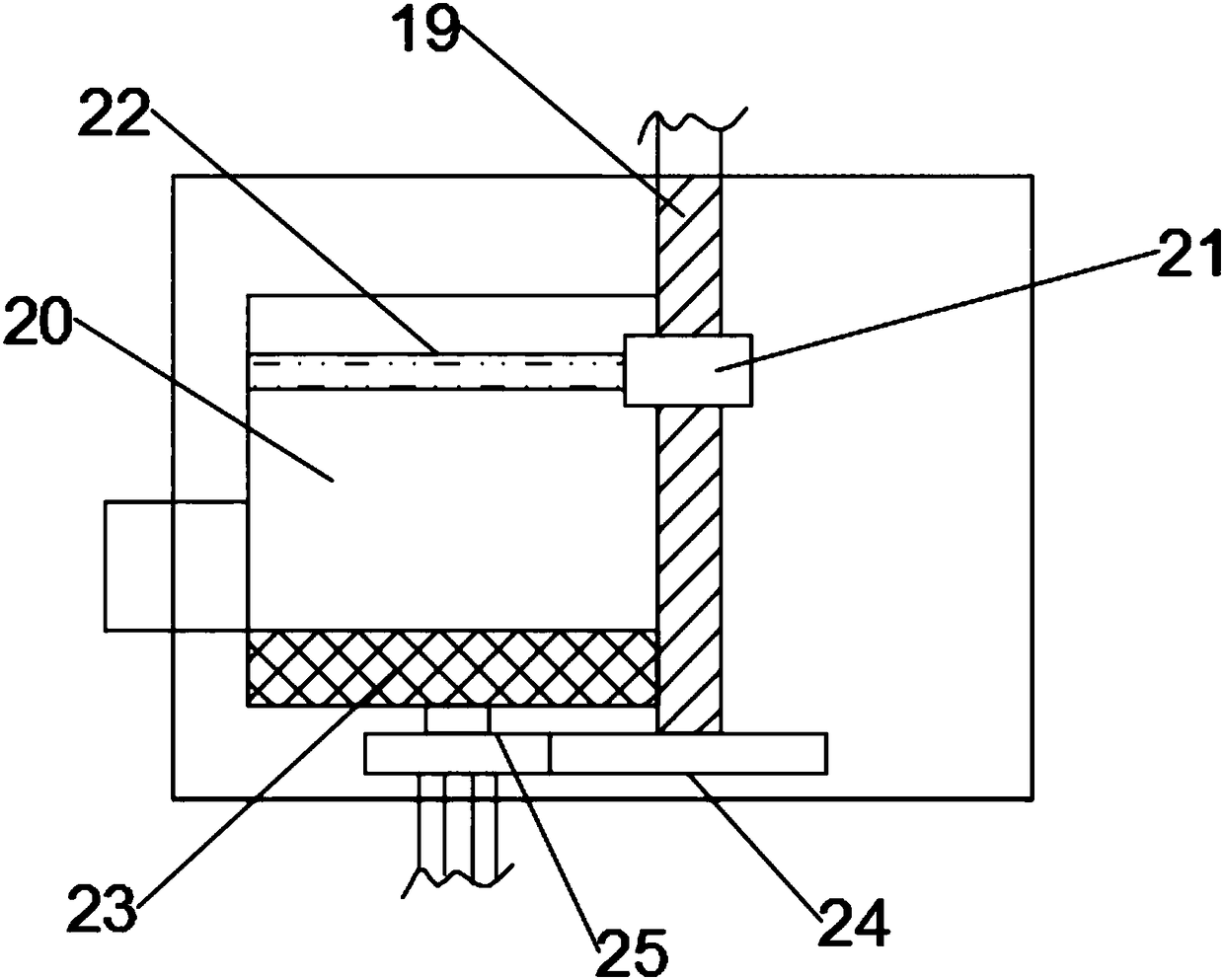

[0022] see Figure 1-5, a device that fully realizes solid-liquid separation of medical waste, including a body 1, a support arm 2, a base 3, a material inlet 4, a separation chamber 5, a sewage outlet 6, and a motor 9, the base 3 is installed on the lower part of the body 1, and the The support arm 2 is installed on the upper left side of the base 3, and the crushing chamber 7 is arranged on the right side of the support arm 2, and the discharge port 8 is installed on the bottom of the crushing chamber 7, and the right side of the crushing chamber 7 is connected to the separation chamber 5 through a connecting pipe 36. , the upper part of the separation chamber 5 is provided with a material inlet 4, the lower part of the separation chamber 5 is provided with a sewage outlet 6, and the left side of the separation chamber 5 is provided wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap