Fixing piece and fixing method for large-size annular bonded NdFeB magnet cutting and shaping

A large-size, NdFeB technology, which is applied in the field of large-size annular bonded NdFeB magnet cutting and repairing fixtures and fixings, can solve problems such as poor clamping accuracy, low clamping efficiency, and easy powder jamming. Achieve the effect of long service life, reasonable structure design and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

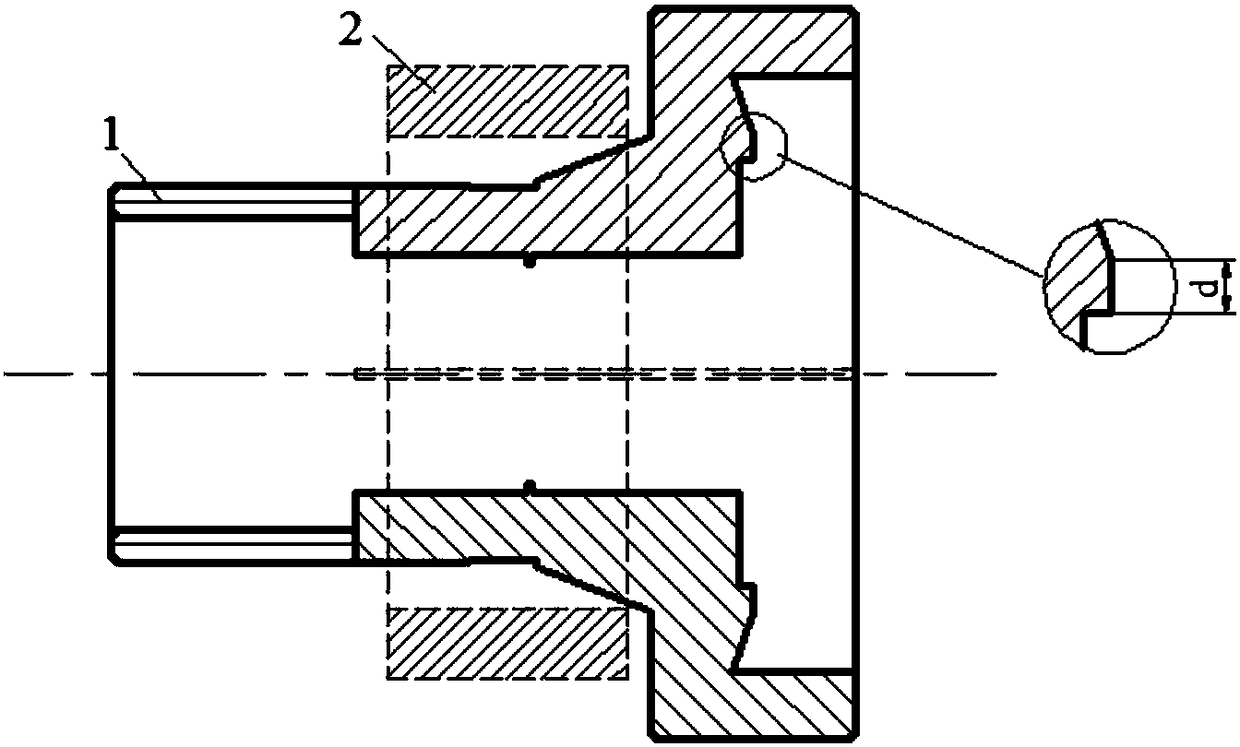

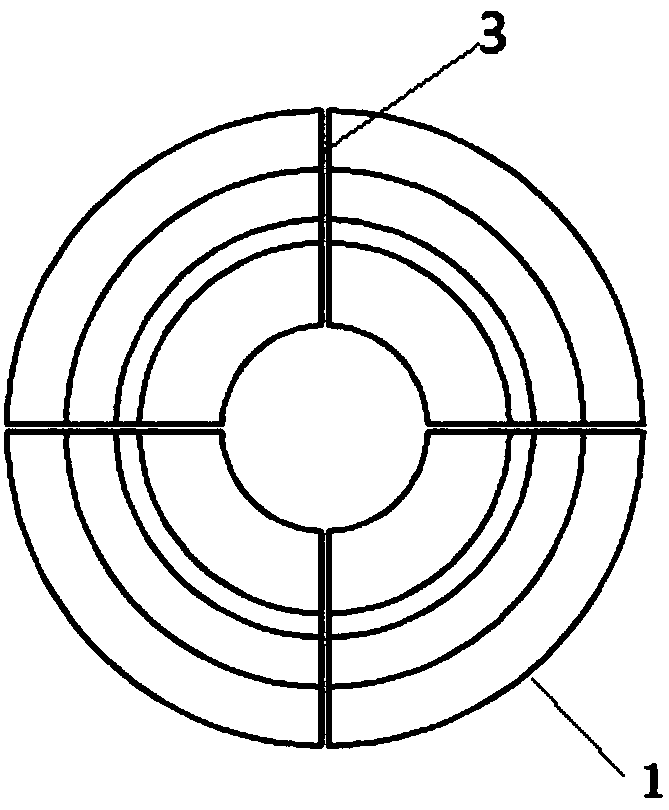

[0042] like Figure 1-2 As shown, a kind of large-size annular bonded NdFeB magnet cutting and repairing fixture of the present invention includes a chuck 1 and a clamp 2 for constraining the chuck 1 to realize its expansion and clamping, wherein:

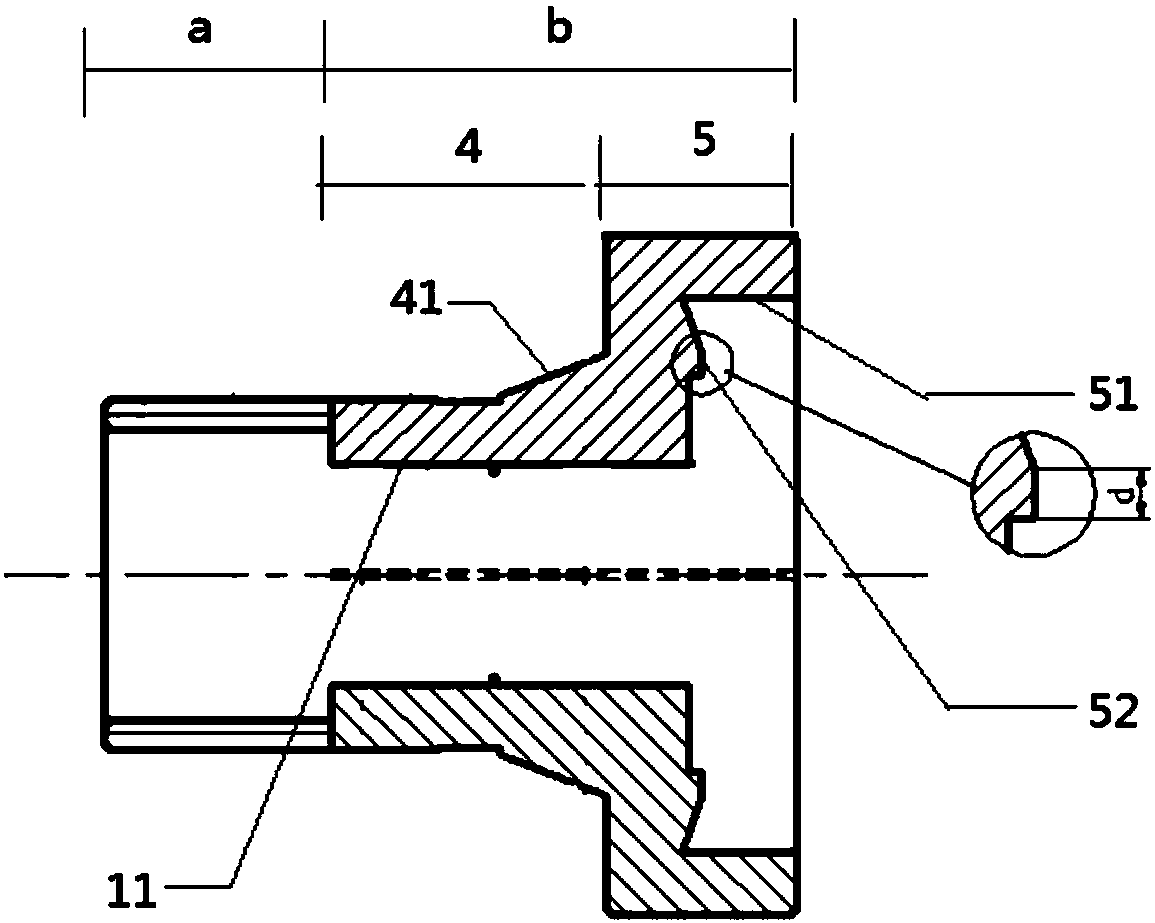

[0043] like Figure 2-3 As shown, the axial center of the chuck 1 is provided with a cavity 11, including a connecting portion a and a positioning portion b, and the side wall of the positioning portion is provided with at least one clamp for realizing expansion and contraction of the positioning portion. The groove 3, the positioning part b includes an enabling section 4 and a snap ring section 5, the outer wall of the enabling section 4 is provided with a tapered surface 41, and the front part of the snap ring section 5 is formed with a The fixed cavity 51, the bottom end of the fixed cavity 51 is provided with a protruding fixed surface 52;

[0044] The clamp 2 is sleeved on the outside of the chuck 1, and relatively moves alo...

Embodiment 2

[0056] In order to increase the contact area between the clamp 2 and the chuck 1 and reduce the contact stress, this embodiment is improved on the basis of embodiment 1, as Figure 4 As shown, the clamp 2 includes a ring structure, and the inner wall of the ring structure is provided with a driving tapered surface 21 .

Embodiment 3

[0058] This embodiment is improved on the basis of embodiment 1 or 2, as Figure 5 As shown, the inside of the fixing surface 54 is provided with a right-angle groove 53 , and the outside of the fixing surface 54 is provided with a V-shaped groove 54 .

[0059] The arrangement of the right-angle groove 53 and the V-shaped groove 54 can effectively reduce the width of the positioning surface, and the setting of the V-shaped groove 54 can make the debris generated by the mode cutting remain on the positioning surface 52, and the debris can be removed under the influence of its own gravity. Slide down along the slope of the V-shaped groove 54 under the action.

[0060] As a preferred manner, the included angle of the V-shaped surface of the V-shaped groove 54 is an acute angle, and the angle is 30°-60°.

[0061] As a preferred mode, the material of the chuck 1 is 65Mn steel, which is quenched at 800°C and then tempered at a medium temperature of 320°C to ensure that the chuck has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com