Hole drilling machine for indoor decoration of building

A technology for interior decoration and drilling machines, which is applied to portable drilling machines, drilling/drilling equipment, electromechanical devices, etc., and can solve the problems of reducing decoration work efficiency, long cooling time, and wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

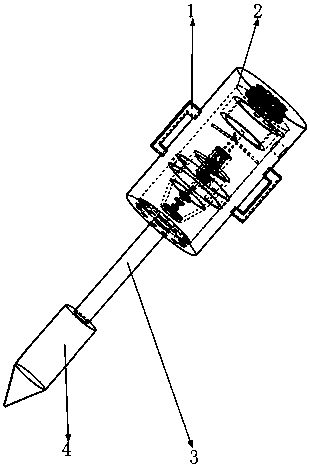

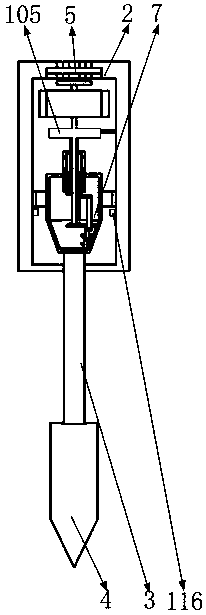

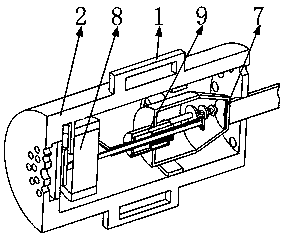

[0059] Such as figure 1 , 2 , shown in 3, it comprises variable speed cone mechanism 7, compressor 9, condenser 5, evaporator 24, fixture 103, wherein variable speed cone mechanism 7, compressor 9, condenser 5, evaporator 24 are all installed in fixture 103 inside.

[0060] Such as Figure 4 , 5 As shown, the above-mentioned fixing device 103 includes a handle 1, a casing 2, a heat dissipation hole 10, an air intake hole 13, and a through hole 14, wherein there are many heat dissipation holes 10 on the inner wall of the rear end of the casing 2; Figure 4 As shown, there are many air intake holes 13 on the front end face of the shell 2; Figure 4 As shown, there is a through hole 14 on the end face of the air inlet 13 on the casing 2, and the axis of the through hole 14 coincides with the axis of the casing 2; Figure 4 As shown, the two handles 1 are symmetrically installed on the outer surface of the housing 2 and are close to the cooling holes 10 .

[0061] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com