Continuous tank-type wood carbonization device

A carbonization device and carbonization technology, applied in the direction of burning charcoal/combustion, can solve the problems of deformation and cracking, inability to carbonize wood, poor carbonization effect, etc., to reduce heat loss, improve transfer efficiency, and improve the effect of carbonization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

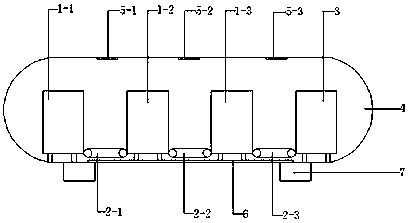

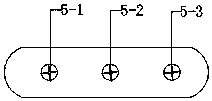

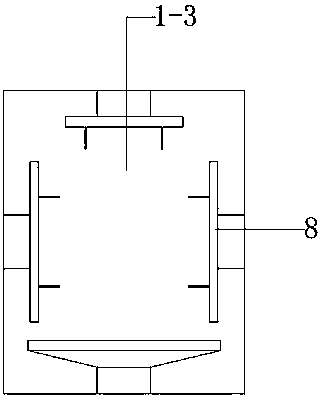

[0022] A continuous tank-type wood carbonization device, mainly including a carbonization device 1, a conveying device 2, a spray cooling chamber 3, a water tank 6 and a tank body 4, characterized in that: the carbonization device 1 contains three carbonization boxes, which are respectively No. 1 carbonization box 1-1, No. 2 carbonization box 1-2 and No. 3 carbonization box 1-3, the upper end of the tank body contains a cooling fan 5; the front end of the device is No. 1 carbonization box 1-1, and the rear of No. 1 carbonization box 1-1 is connected with No. 1 conveying device 2-1, No. 1 conveying device 2-1 is connected with No. 2 carbonization box 1-2, No. 2 carbonization box 1-2 is connected with No. 2 conveying device 2-2, No. 2 conveying device 2- After 2, No. 3 carbonization box 1-3 is connected, and No. 3 carbonization box 1-3 is connected with spray cooling chamber 3 through No. 3 conveying device 2-3, of which No. 2 carbonization box 1-2 and No. 3 carbonization box 1- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com