One-way chain transmission multi-stage sleeve type folding and unfolding mechanism

A sleeve-type and chain-driven technology, which is used in motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of limited use of process space, large space occupied, complex structure, etc., so as to achieve full utilization of process space, The effect of small space occupation and large exhibition-to-retract ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

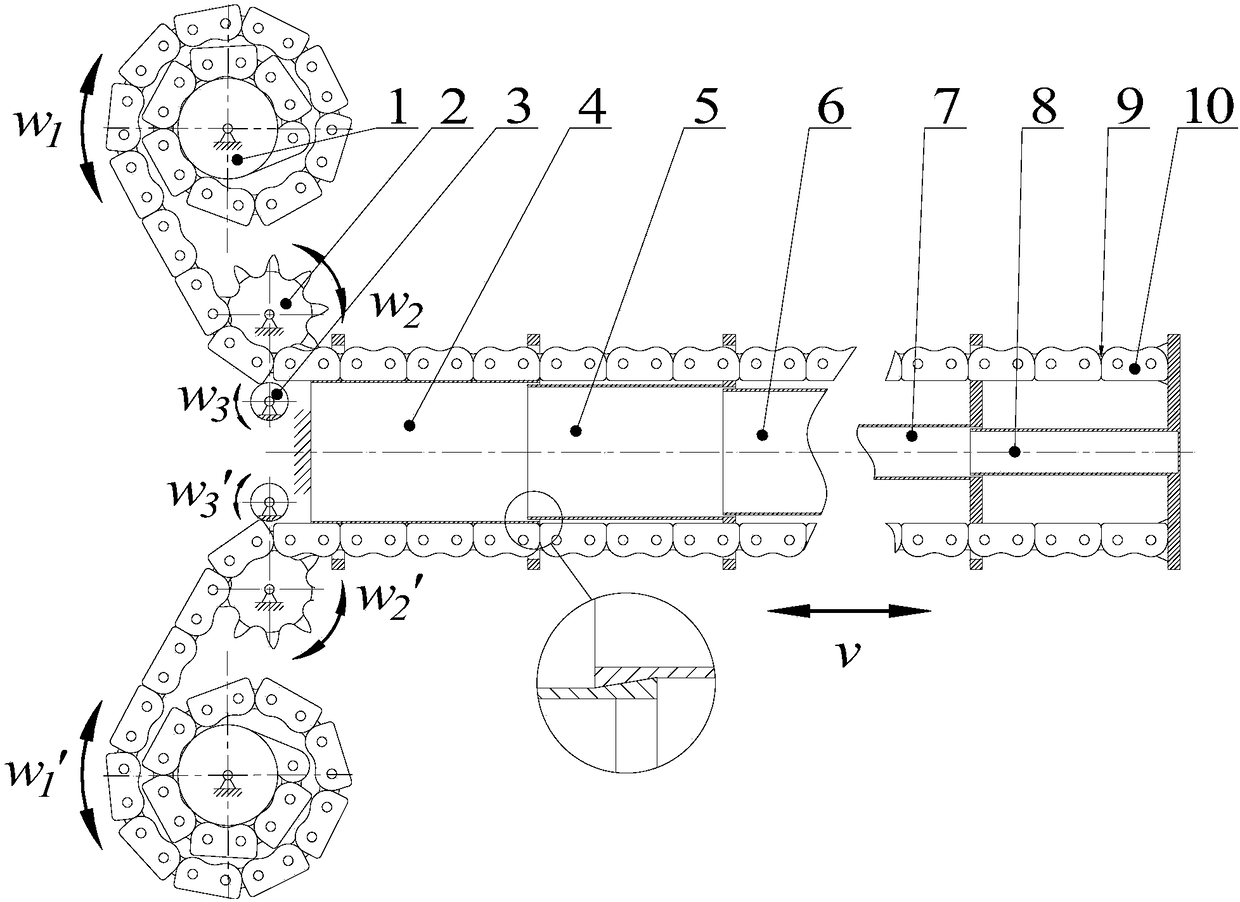

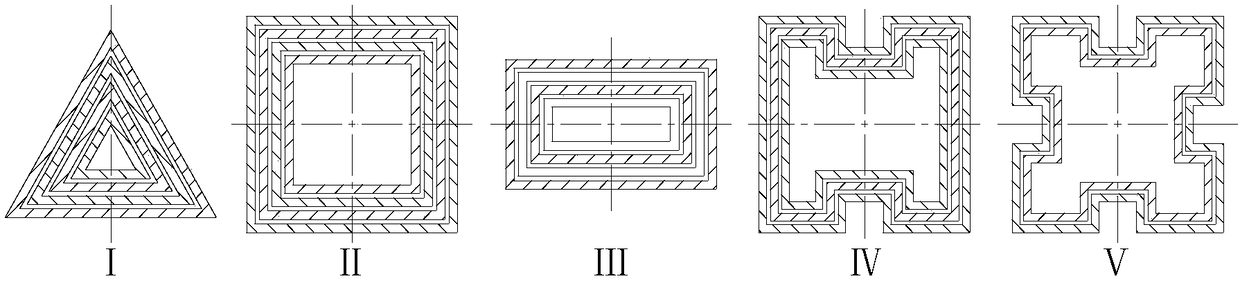

[0021] Specific implementation mode one, see figure 1 with image 3 Describe this embodiment, where, ω 1 , ω 2 and ω 3 Indicates the angular velocity, and v indicates the linear velocity. A one-way chain drive multi-stage sleeve-type outer drive retracting mechanism described in this embodiment includes two winding sprockets 1, two sprockets 2, two sets of support wheels 3, two sets of one-way chains and a multi-stage In the sleeve module, the two sprocket 1, sprocket 2, support wheel 3, and one-way chains are arranged oppositely and driven synchronously, and the sprocket 1, sprocket 2, and multi-stage sleeve modules are synchronously driven through the one-way chain , the support wheel 3 is under the sprocket 2, and is used to support the one-way chain; the multi-stage sleeve module is formed by nesting n hollow sleeves, wherein n≥2, the multi-stage sleeve module The slopes of the inner wall and the outer wall at the junction of the end faces of adjacent sleeves are diff...

specific Embodiment approach 2

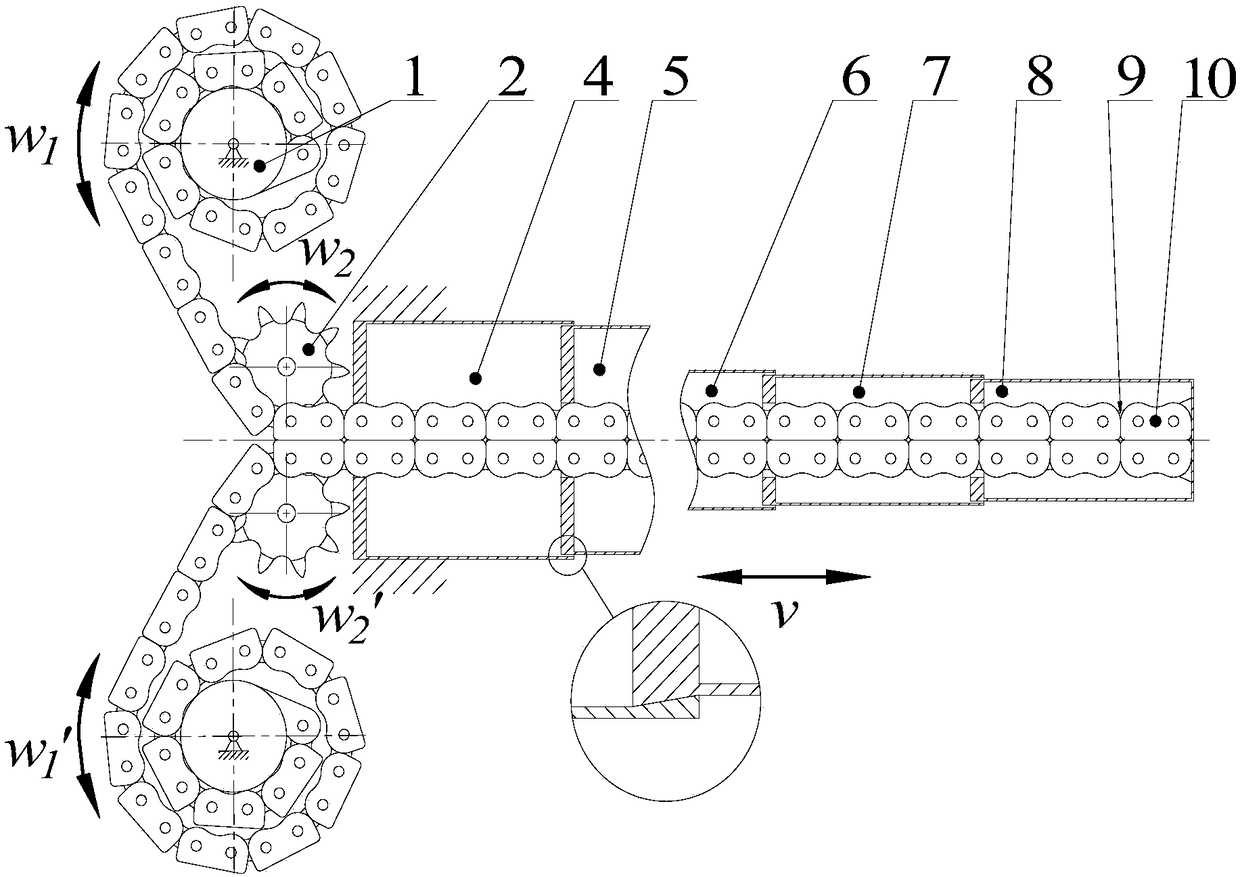

[0035] Specific implementation mode two, see figure 2 with image 3 Describe this embodiment, where, ω 1 , ω 2 and ω 3 Indicates the angular velocity, and v indicates the linear velocity. A one-way chain drive multi-stage sleeve-type internal drive retracting mechanism described in this embodiment includes two winding sprockets 1, two sprockets 2, two sets of one-way chains and a multi-stage sleeve module, two The sprocket 1, the sprocket 2, and the one-way chain are relatively arranged and driven synchronously. The sprocket 1, the sprocket 2, and the multi-stage sleeve module are synchronously driven by the one-way chain, and the sprockets 2 are opposite to each other. Play a supporting role and clamp the one-way chain; the multi-stage sleeve module is formed by nesting n hollow sleeves, where n≥2, the inner wall of the joint of the end faces of the adjacent sleeves of the multi-stage sleeve module Unlike the slope of the outer wall, the one-way chain is located inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com