A printing and dyeing wastewater treatment method for cationic dyes

A cationic dye, printing and dyeing wastewater technology, applied in water/sewage treatment, water/sewage multi-stage treatment, special compound water treatment, etc. Achieve good regeneration efficiency, ensure decolorization effect, and effect of good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

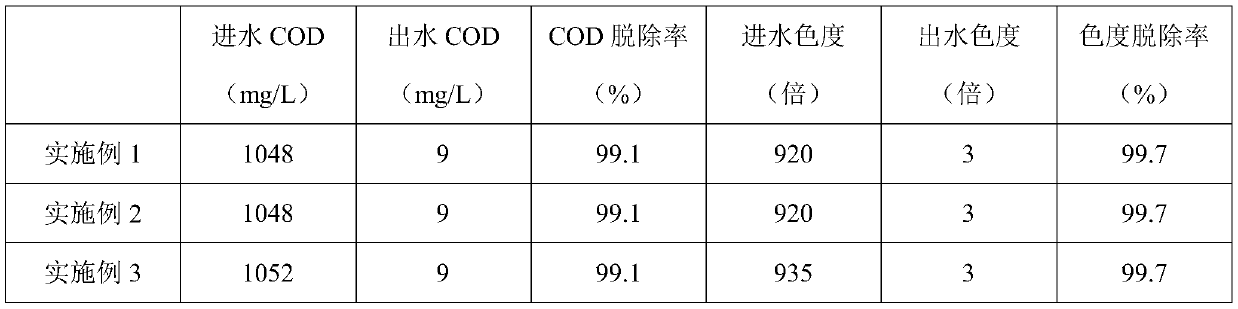

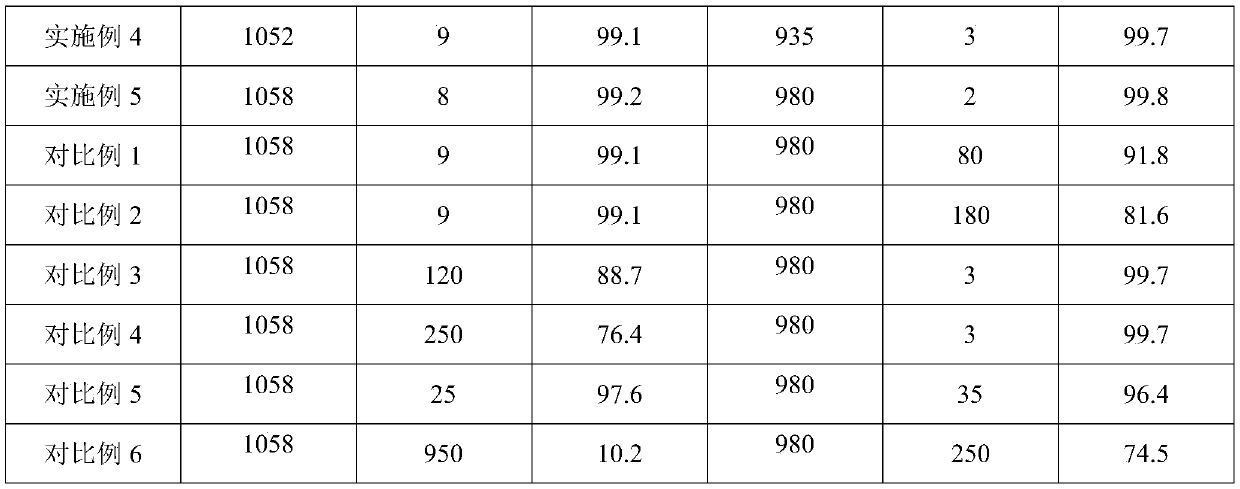

Examples

Embodiment 1

[0034] A printing and dyeing wastewater treatment method for cationic dyes, the specific steps are as follows:

[0035] (1) Pre-test: detect the pigment component (basic violet 5BN) and its molar concentration of the cationic dye contained in the printing and dyeing wastewater;

[0036] (2) Static adsorption: Add an adsorbent to the printing and dyeing wastewater at a dosage of 0.8g / L, perform static adsorption for 30 minutes, filter to obtain the first treatment solution, and regenerate the adsorbent;

[0037] (3) Foam separation and decolorization: adjust the pH of the first treatment solution to 8, add an anionic surfactant, and use a bubble tower with a tower diameter of 32 mm to carry out decolorization treatment, the temperature is 16 ° C, and the gas volume flow rate is 0.005 m 3 / h, the height of the foam layer is 0.6m, and the decolorization treatment time is 20 minutes. After the foam layer is broken, the foam solution is obtained, and the cationic dye crude product ...

Embodiment 2

[0044] A printing and dyeing wastewater treatment method for cationic dyes, the specific steps are as follows:

[0045] (1) Pre-test: detect the pigment component (basic violet 5BN) and its molar concentration of the cationic dye contained in the printing and dyeing wastewater;

[0046] (2) Static adsorption: Add an adsorbent to the printing and dyeing wastewater at a dosage of 1 g / L, perform static adsorption for 40 minutes, filter to obtain the first treatment solution, and regenerate the adsorbent;

[0047] (3) Foam separation and decolorization: adjust the pH of the first treatment solution to 9, add an anionic surfactant, and use a bubble column with a tower diameter of 32mm to perform decolorization treatment at a temperature of 20°C and a gas volume flow rate of 0.007m 3 / h, the height of the foam layer is 0.8m, and the decolorization treatment time is 30 minutes. After the foam layer is broken, the foam solution is obtained, and the cationic dye crude product and the f...

Embodiment 3

[0054] A printing and dyeing wastewater treatment method for cationic dyes, the specific steps are as follows:

[0055] (1) Pre-test: detect the pigment component (basic brilliant blue BO) and its molar concentration of the cationic dye contained in the printing and dyeing wastewater;

[0056] (2) Static adsorption: Add an adsorbent to the printing and dyeing wastewater at a dosage of 0.8g / L, statically adsorb for 40 minutes, filter to obtain the first treatment solution, and regenerate the adsorbent;

[0057] (3) Foam separation and decolorization: adjust the pH of the first treatment solution to 8, add an anionic surfactant, and use a bubble tower with a tower diameter of 32mm to carry out decolorization treatment at a temperature of 20°C and a gas volume flow rate of 0.005m 3 / h, the height of the foam layer is 0.8m, and the decolorization treatment time is 20 minutes. After the foam layer is broken, the foam solution is obtained, and the cationic dye crude product and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com