A kind of preparation method of graphene oxide reinforced cement-based mortar material

A technology for mortar materials and reinforced cement, which is applied in the field of preparation of graphene oxide reinforced cement-based mortar materials, and can solve problems such as agglomeration and flocculation, limiting the function of graphene oxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

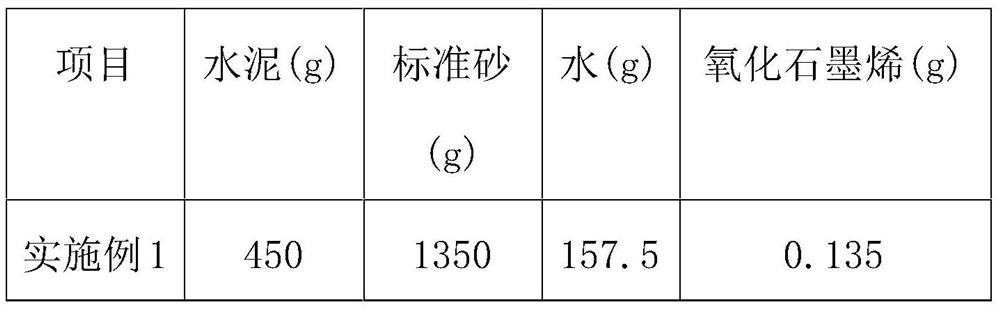

[0020] Weigh each component by weight as shown in the table below:

[0021]

[0022] The cement used in Example 1 is 42.5 grade ordinary Portland cement, the standard sand is produced by Xiamen Aisou Standard Sand Co., Ltd., the particle size is 1-5 μm, and the water is deionized water. The selected graphene oxide sheet diameter is 2 μm, the oxygen content rate is 30%, and the number of layers is 2 layers; the graphene oxide is added to deionized water and ultrasonically dispersed, the ultrasonic condition is 200W, the frequency is 40KHz, and the ultrasonic dispersion time The time is 30min; soak the obtained dispersion in liquid nitrogen for 30s to obtain ice cubes of the graphene oxide dispersion; add the ice cubes to the stirring pot under the operating condition of 3°C and stir the ice cubes at a low speed first. Broken, then continue to stir at low speed and add the weighed standard sand within 8s. After stirring for 3 minutes, add the weighed cement, and the cement is...

Embodiment 2

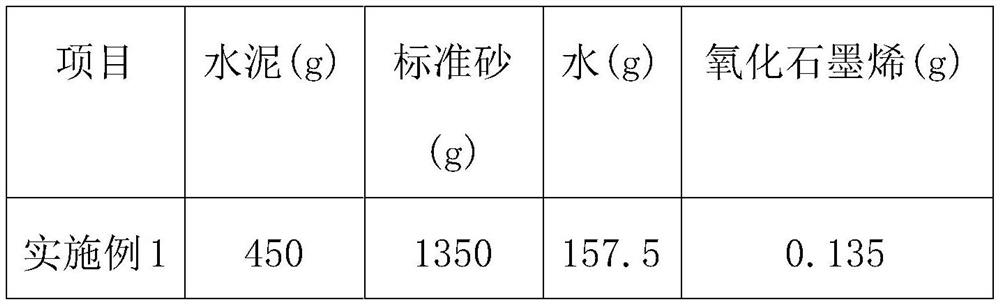

[0029] Weigh each component by weight as shown in the table below:

[0030]

[0031] The cement used in Example 2 is 42.5 grade ordinary Portland cement, the standard sand is produced by Xiamen Aisou Standard Sand Co., Ltd., the particle size is 1-5 μm, and the water is deionized water. The selected graphene oxide sheet diameter is 5 μm, the oxygen content rate is 50%, and the number of layers is 5 layers; the graphene oxide is added to deionized water and ultrasonically dispersed, the ultrasonic condition is 280W, the frequency is 60KHz, and the ultrasonic dispersion time The time is 30min; soak the obtained dispersion in liquid nitrogen for 90s to obtain ice cubes of the graphene oxide dispersion; add the ice cubes to the stirring pot under the operating condition of 1°C and stir the ice cubes at a low speed first. Broken, then continue to stir at low speed and add the weighed standard sand within 10s. After stirring for 4min, add the weighed cement, and the cement is add...

Embodiment 3

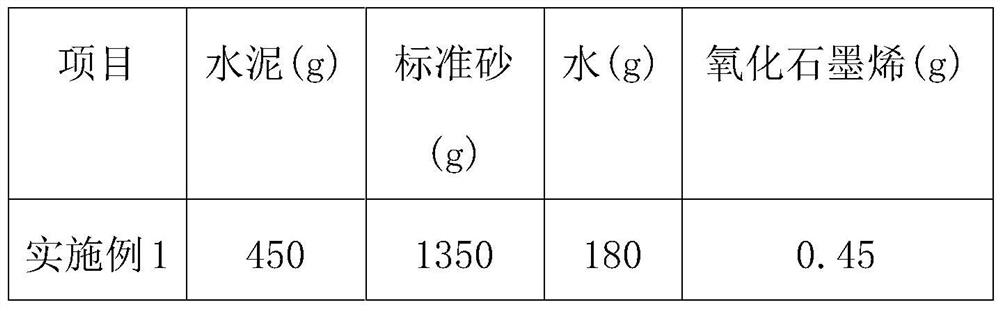

[0038] Weigh each component by weight as shown in the table below:

[0039]

[0040] The cement used in Example 3 is 42.5 grade ordinary Portland cement, the standard sand is produced by Xiamen Aisou Standard Sand Co., Ltd., the particle size is 1-5 μm, and the water is deionized water. The selected graphene oxide sheet diameter is 10 μm, the oxygen content rate is 60%, and the number of layers is 10 layers; the graphene oxide is added to deionized water and ultrasonically dispersed, the ultrasonic condition is 280W, the frequency is 80KHz, and the ultrasonic dispersion time The time is 60min; soak the obtained dispersion in liquid nitrogen for 180s to obtain ice cubes of the graphene oxide dispersion; add the ice cubes to the stirring pot under the operating condition of 0°C and stir the ice cubes at a low speed first. Crushing, then continue to stir at low speed and add the weighed standard sand within 10s, after stirring for 5 minutes, then add the weighed cement, the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com