Electric gate valve

An electric gate valve and valve body technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of inconvenient installation, poor sealing, complex structure, etc., and achieve the effect of convenient installation, good sealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

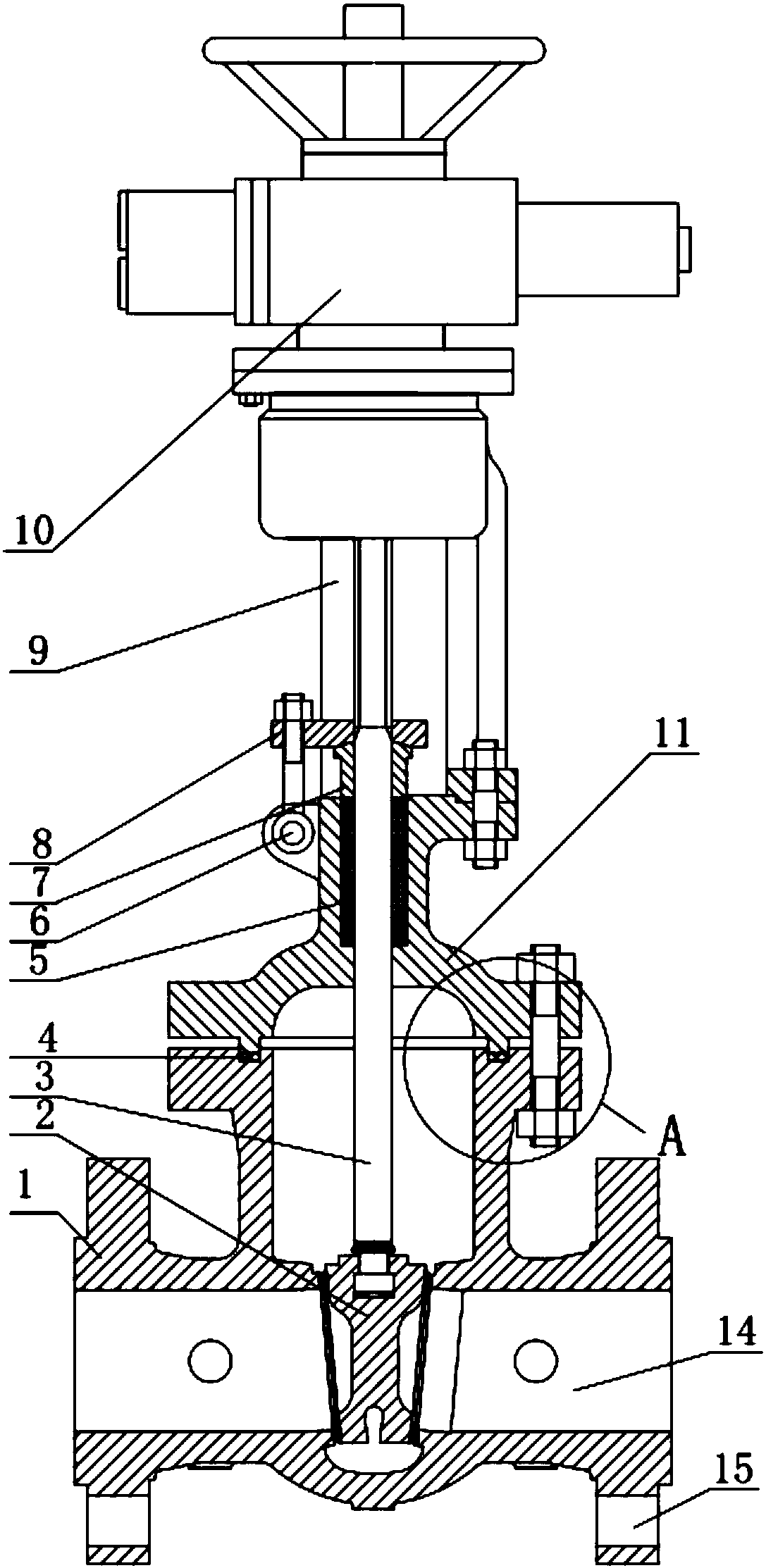

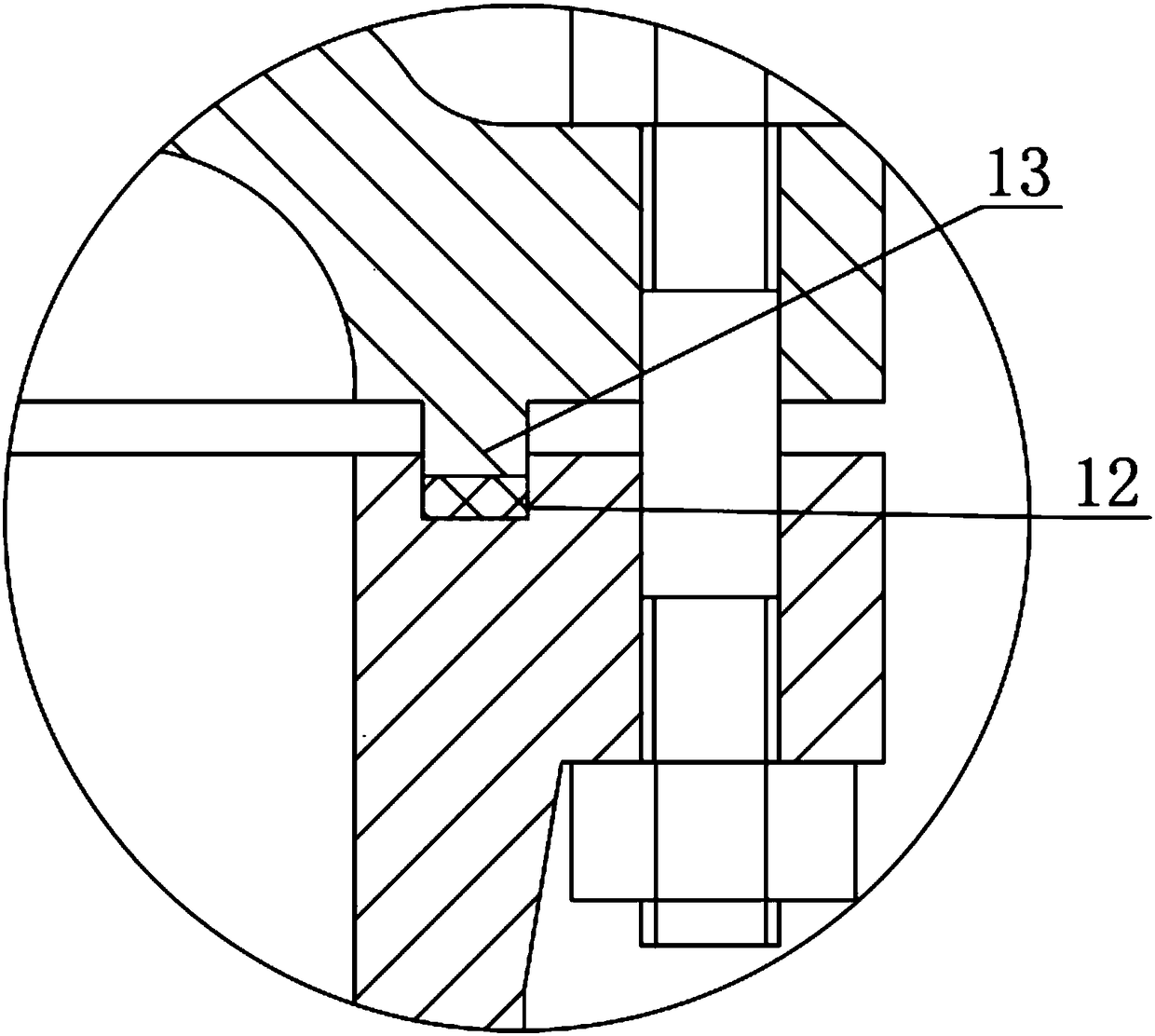

[0015] Such as figure 1 As shown, an electric gate valve of the present invention includes a valve body 1, a gate plate 2, a valve stem 3, a gasket 4, a packing 5, a positioning pin 6, a pressure sleeve 7, a pressure plate 8, a bracket 9, a driving motor 10 and a valve Cover 11; the gate plate 2 is installed at the middle position inside the valve body 1; the lower end of the valve stem 3 cooperates with the gate plate 2, and the upper end is coaxially connected with the driving motor 10 through the valve cover 11; The gasket 4 is clamped and fixed in the groove on the upper end of the valve body 1; the valve cover 11 is fixedly installed on the upper end of the valve bod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap