Hot strip sampling method

A hot continuous rolling and strip steel technology, applied in the field of metallurgy, can solve the problems of slowing down the production rhythm, reducing the yield of products, and increasing the work intensity of on-site sampling workers, so as to speed up the pace of production, increase the yield of products, and reduce the work intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

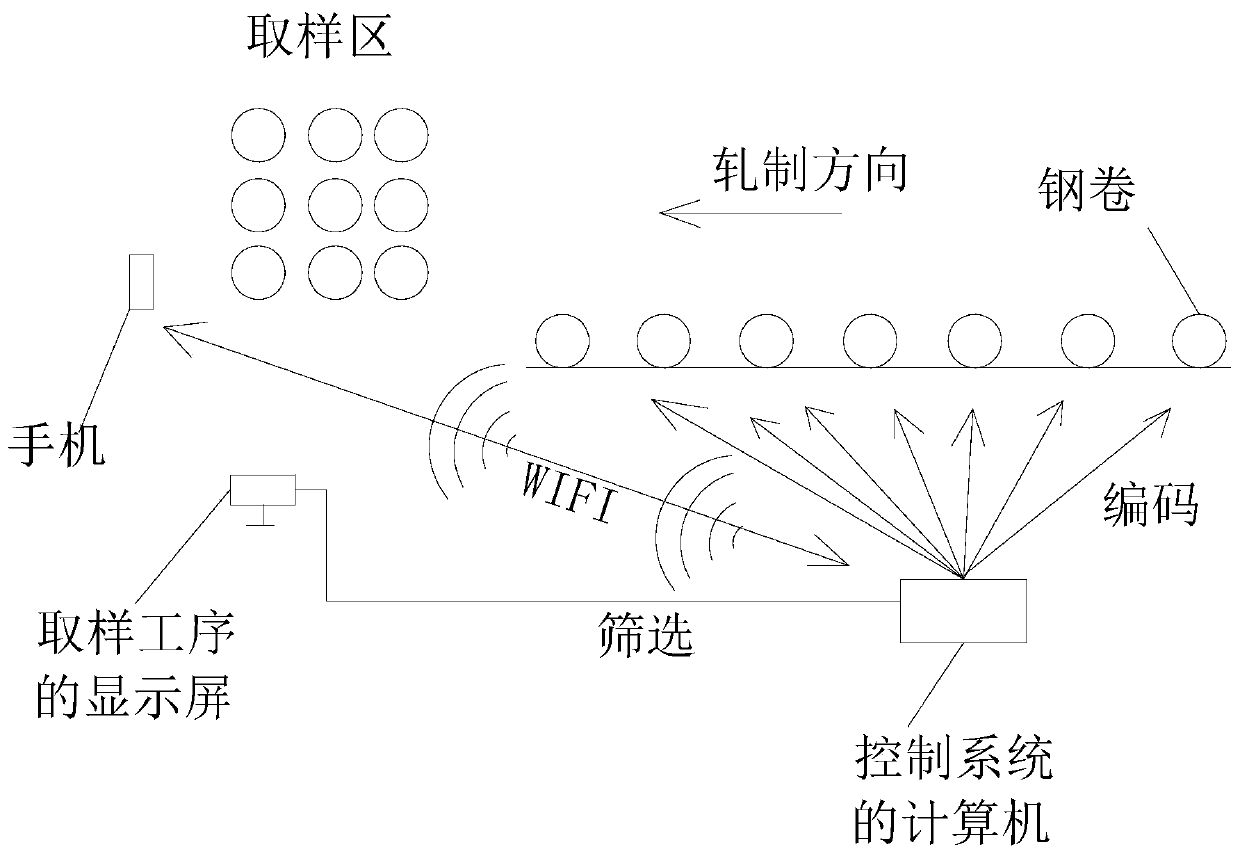

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

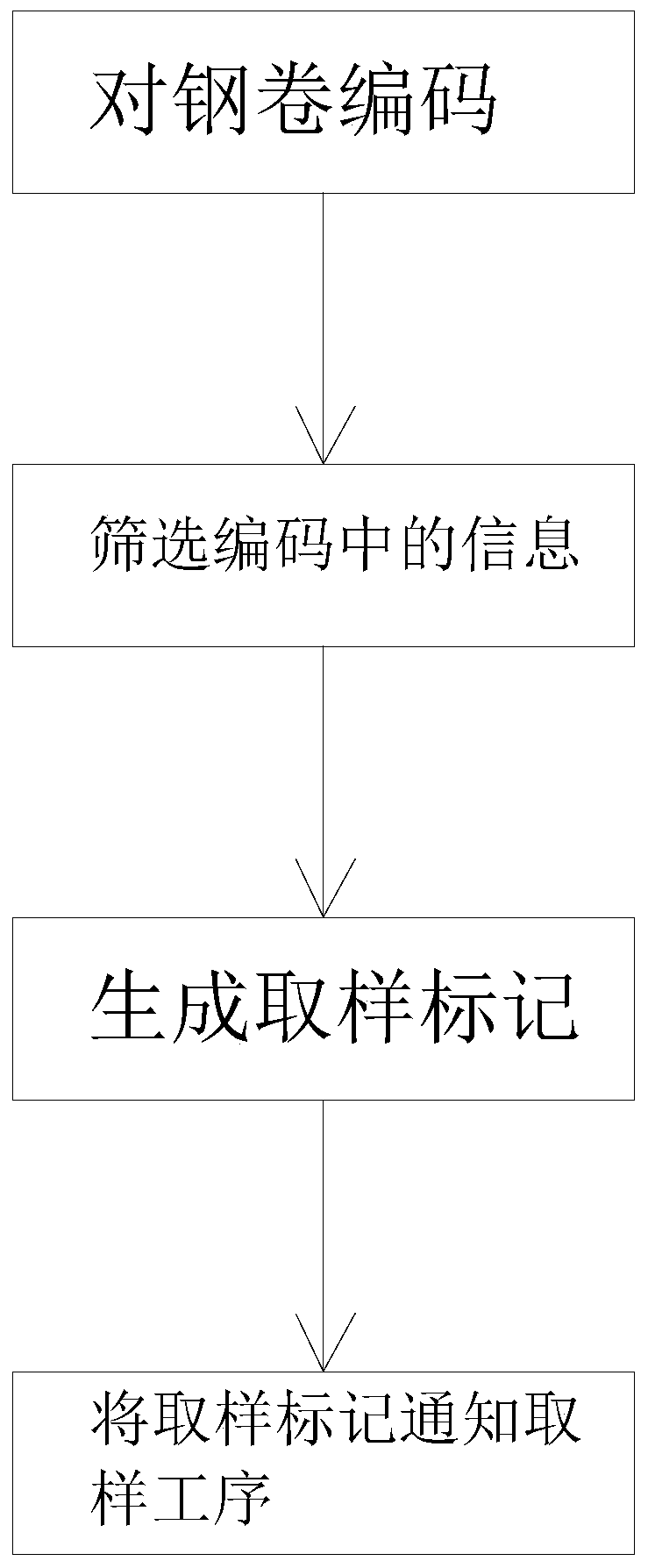

[0030] like figure 1 and figure 2 Shown, the present invention proposes a kind of hot rolling strip sampling method of the present invention, comprises:

[0031] Step A: Generation of steel coil identity information:

[0032] The computer of the production control system makes a rolling plan before rolling, and codes each steel coil to be rolled in advance to form the identity information of the steel coil (that is, the coil number), the code on each steel coil and the rolling code. Manufacturing plan information includes at least: contract number information, applicable metallurgical specification information, furnace number information, and finished product thickness and width specification information; codes are, for example, numbers, letters, or combinations of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com