Machining method of aluminum profile hot extrusion mold

A technology of hot extrusion die and processing method, which is applied in the direction of metal extrusion forming tools, metal extrusion, electric processing equipment, etc., can solve problems such as poor cooling effect, shorten processing cycle, increase supply, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

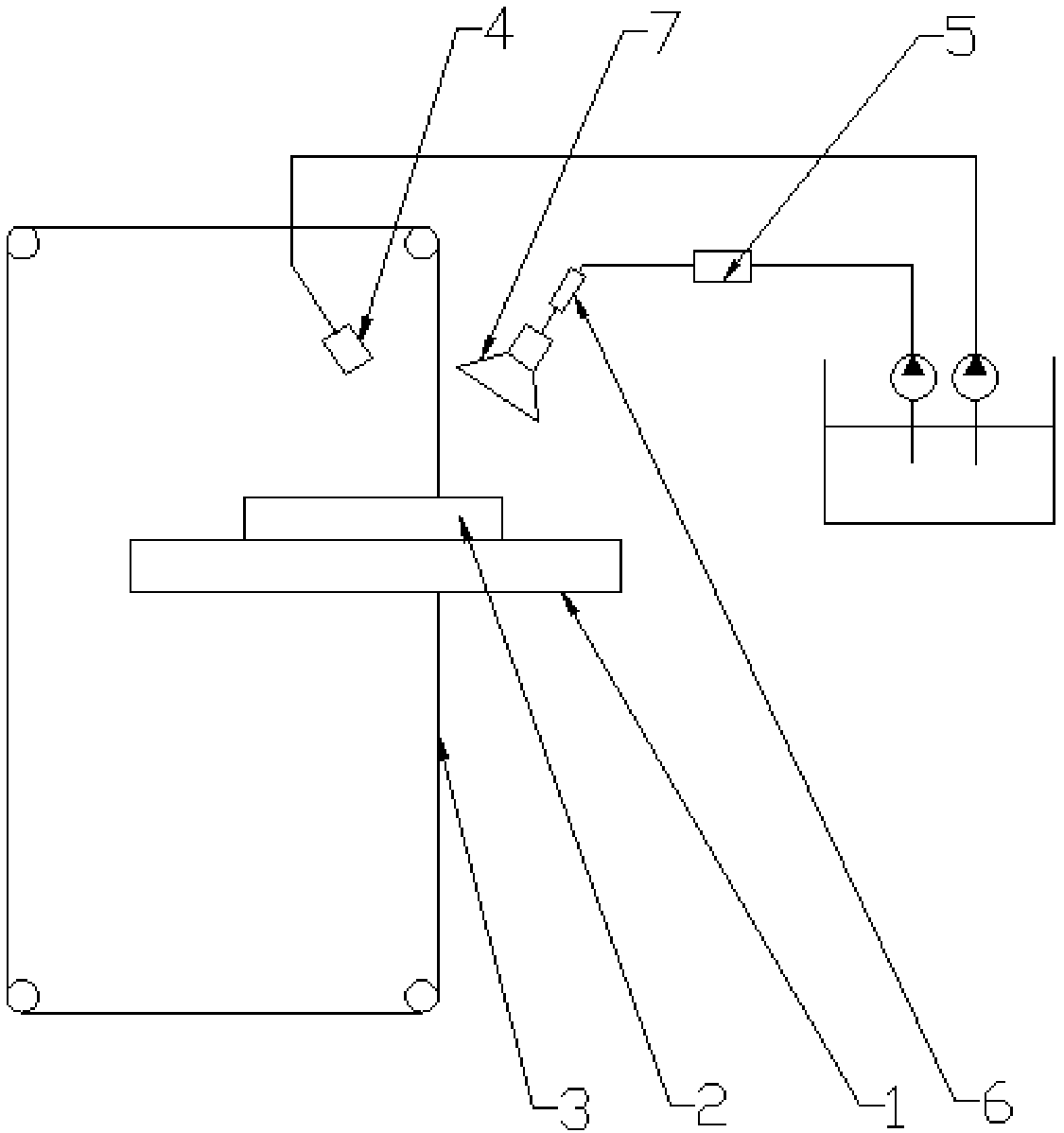

[0041] Embodiment 2, on the basis of Embodiment 1, an atomizing spraying device is also provided on the supply circuit provided with the solenoid valve 5, and the atomizing spraying device includes a pressure valve set on the supply circuit. Regulating valve 6, the pressure regulating valve 6 is used to increase the pressure of the coolant in the supply circuit, the pressure can be properly adjusted through the pressure regulating valve 6, so that it can be adjusted through the pressure regulating valve set on the supply circuit The atomized cooling liquid is formed when the nozzle 4 sprays out. Atomizing the cooling liquid can not only achieve the effect of rapid cooling, but also avoid different degrees of impact on the electrode wire 3 when the cooling liquid is directly sprayed on the electrode wire 3, so that the electrode The wire 3 vibrates, which affects the accuracy of wire cutting. In order to spray the atomized cooling liquid on the wire electrode 3 and the mold bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com