A self-locking nut closing device

A technology of self-locking nut and closing device, which is applied to nuts, threaded fasteners, connecting components, etc., to achieve the effect of convenient operation, simple structure design and solving the problem of closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

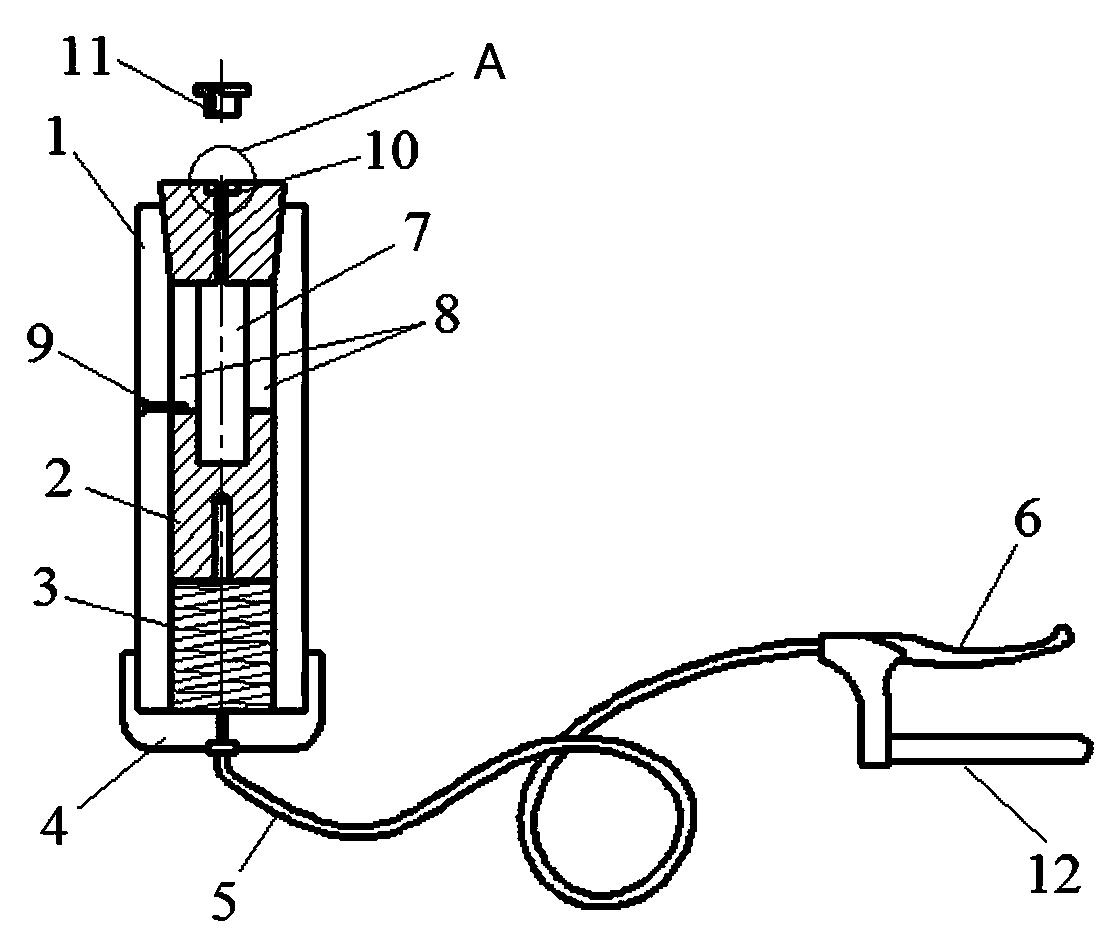

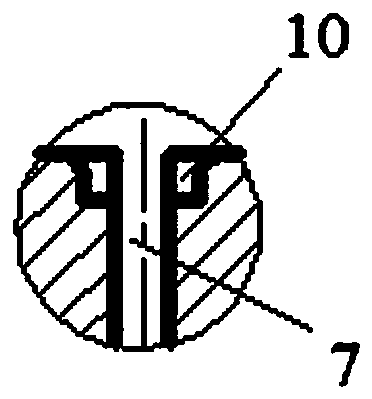

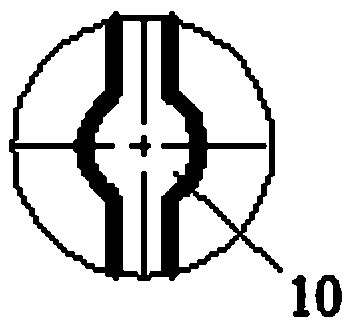

[0027] Such as Figure 1~3 As shown, the self-locking nut closing device is mainly composed of a mold base 1, a closing mold assembly 2, a spring 3, a blocking cover 4, a flexible shaft 5 and a handle. The mold base 1 is a hollow cylinder, and the closing mold assembly 2 and the spring 3 are arranged in the inner cavity of the mold base 1 . The closing die assembly 2 includes a clamping die, a connecting arm and a mounting seat. In this embodiment, there are two clamping dies, and the clamping die, connecting arm and mounting seat are integrated to form the closing die assembly 2 . The closing mold assembly 2 is arranged with a convex-shaped through-groove 7, the groove walls on both sides of the convex-shaped through-groove 7 are closer to form clamping molds, and the groove walls on both sides of the convex-shaped through-groove 7 are farther away. Connecting arm, the groove bottom position of convex-shaped through groove 7 forms mounting seat, and the clamping mold of clos...

Embodiment 2

[0030] Embodiment 2 of the present invention differs from Embodiment 1 in that: the stop structure adopts the internal structure of the telescopic rod, and by setting a convex portion on the outer peripheral surface of the clamping mold, the convex portion can be ring-shaped or a single convex portion Block, the inner side wall of the mold base is provided with an annular stepped convex part matching with the convex part on the clamping mold, and the convex part on the clamping mold and the convex part on the mold base block each other, thereby limiting the displacement of the clamping mold.

Embodiment 3

[0031] Embodiment 3 of the present invention differs from Embodiment 1 in that: the flexible shaft of the closing drive part is in the form of a telescopic rod, the inner rod of the telescopic rod is connected with the clamping mold, and the sleeve of the telescopic rod is fixed on the blocking cover. The sleeve is fixed to the fixed handle, and the inner rod is fixed to the moving handle. The retraction of the telescopic rod is realized by squeezing the moving handle, thereby realizing the axial displacement of the clamping mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com