Lossless and clean transferring method for high-precision large-caliber ultrathin elements

A large-caliber, high-precision technology, applied in the field of super-strong, super-short and high-power lasers, can solve problems such as fragility, component deformation, waste of packaging fixtures, storage space logistics space costs, etc., to ensure cleanliness and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

[0028] Such as figure 1 , figure 2 and image 3 As shown, a non-destructive and clean transfer method for high-precision, large-diameter ultra-thin components, including the following steps:

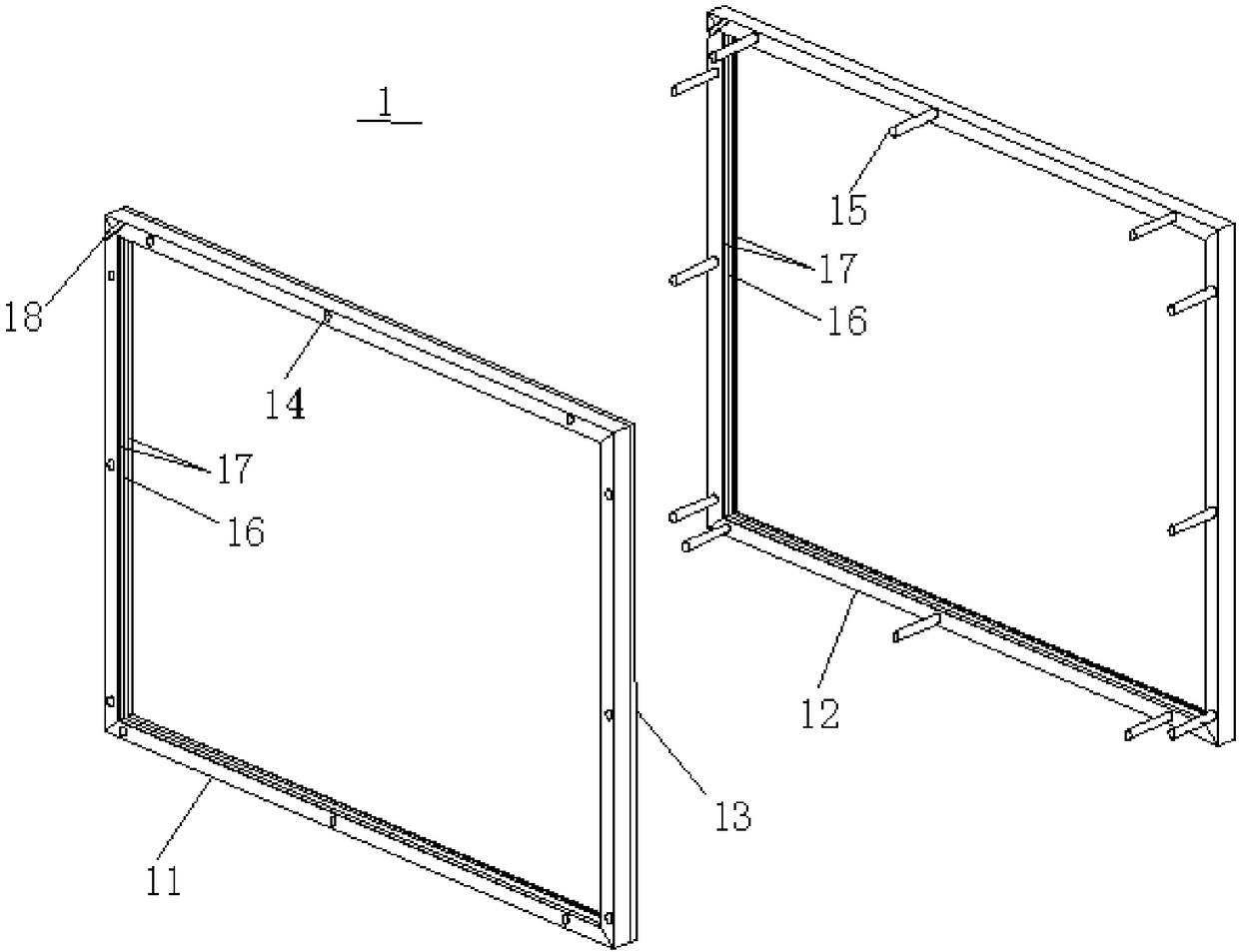

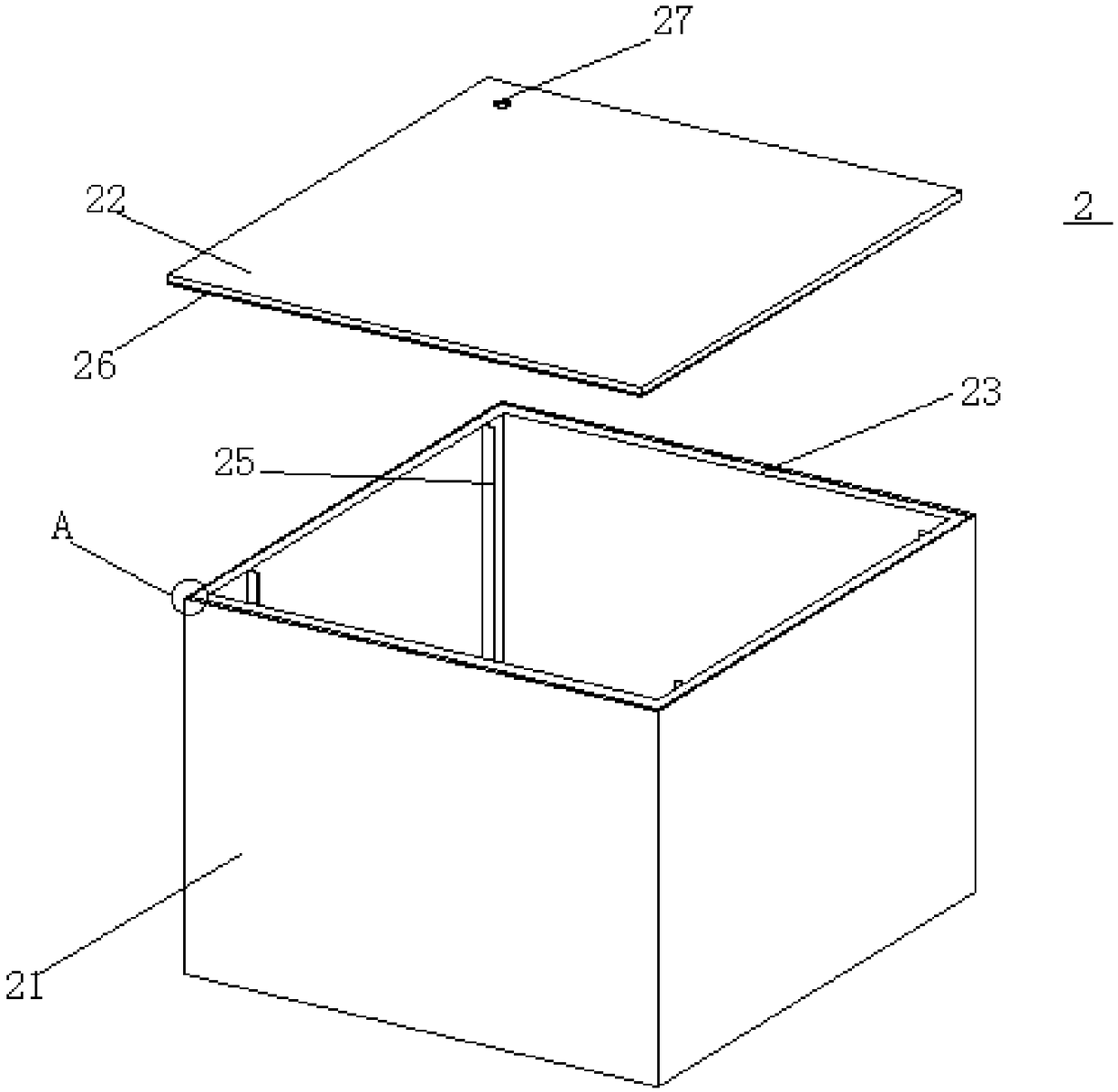

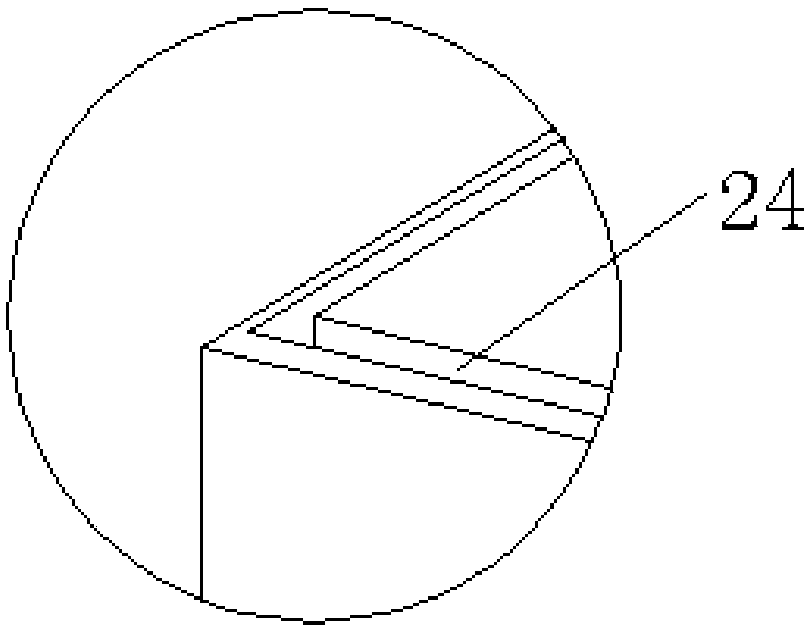

[0029] S1) Fixing of the components; after the components are cleaned, they are loaded into a special support frame 1 in a clean room to fix the components; the support frame 1 includes several female frames 11 and at least one male frame 12, each female frame A side edge of 11 is provided with sealing strip 13, and the side frame of each female frame 11 is provided with several fixing holes 14 at intervals, and the side frame of male frame 12 is provided with several fixing holes for series connection at intervals. The fixed bar 15 of 14, the frame side wall of female frame 11 and male fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com