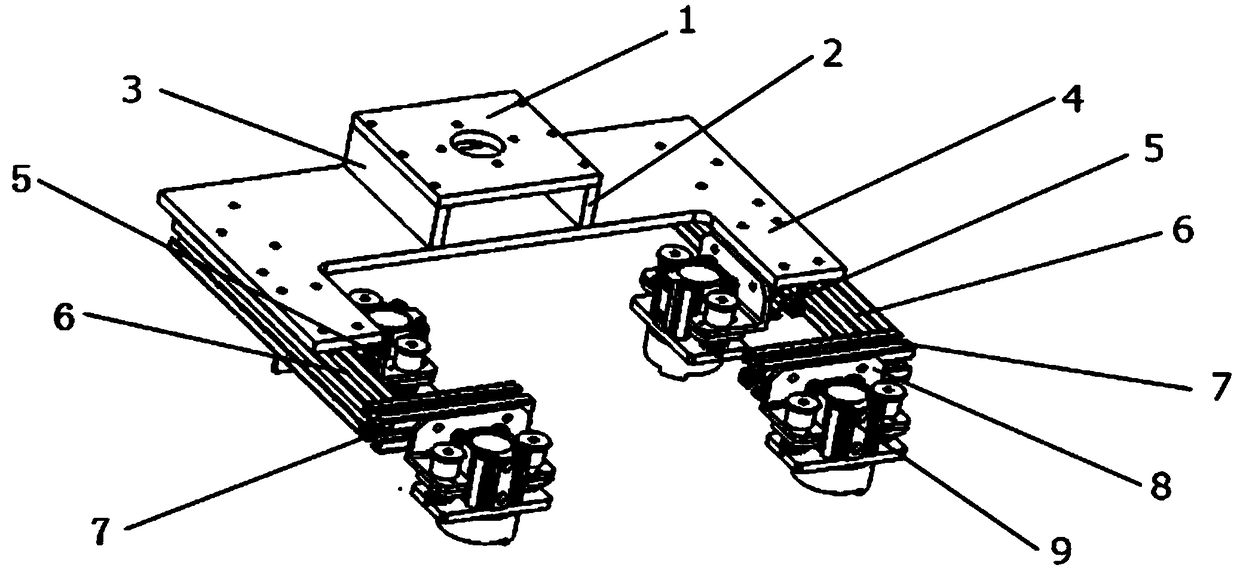

Flexible novel magnetic sucking disc gripper

A magnetic sucker and magnetic adsorption technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as complex structure, low efficiency, assembly errors, etc., to reduce personnel management pressure, reduce labor costs, and improve manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

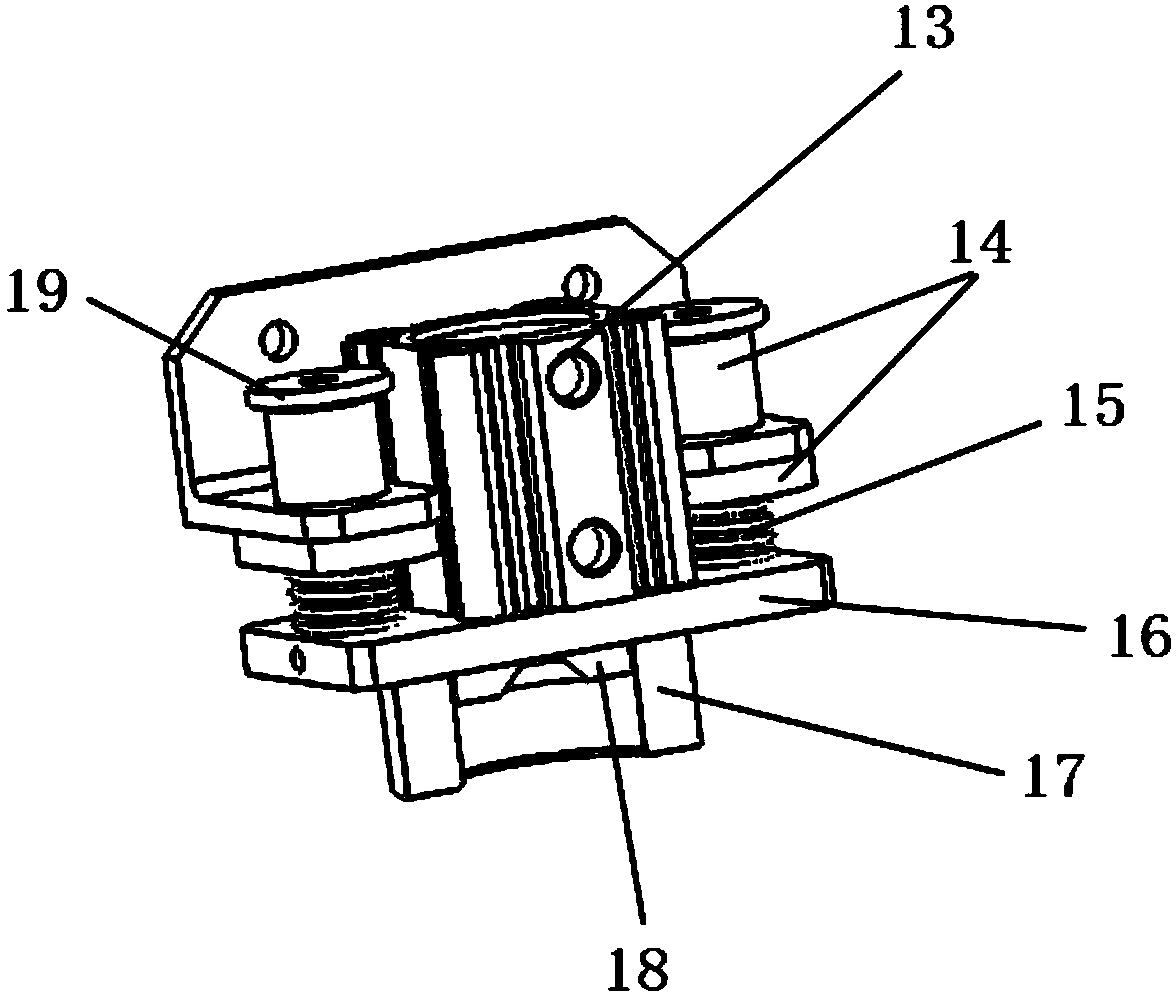

Method used

Image

Examples

Embodiment

[0028] When the flexible novel magnetic chuck gripper of the present invention is combined with a robot in the production field, the specific workflow is as follows: Figure 5 . When the intelligent robot and the flexible new magnetic chuck gripper of the present invention are powered on, when teaching the robot's motion trajectory, problems such as rapid movement and convenient operation during automatic production of the machine should be considered. When the intelligent robot and the flexible new magnetic chuck gripper of the present invention are running, the corresponding module system is selected by the control and operation integrated processing cabinet to work. The structural flow of the module system is as follows:

[0029] S1. Execute the automatic operation work program.

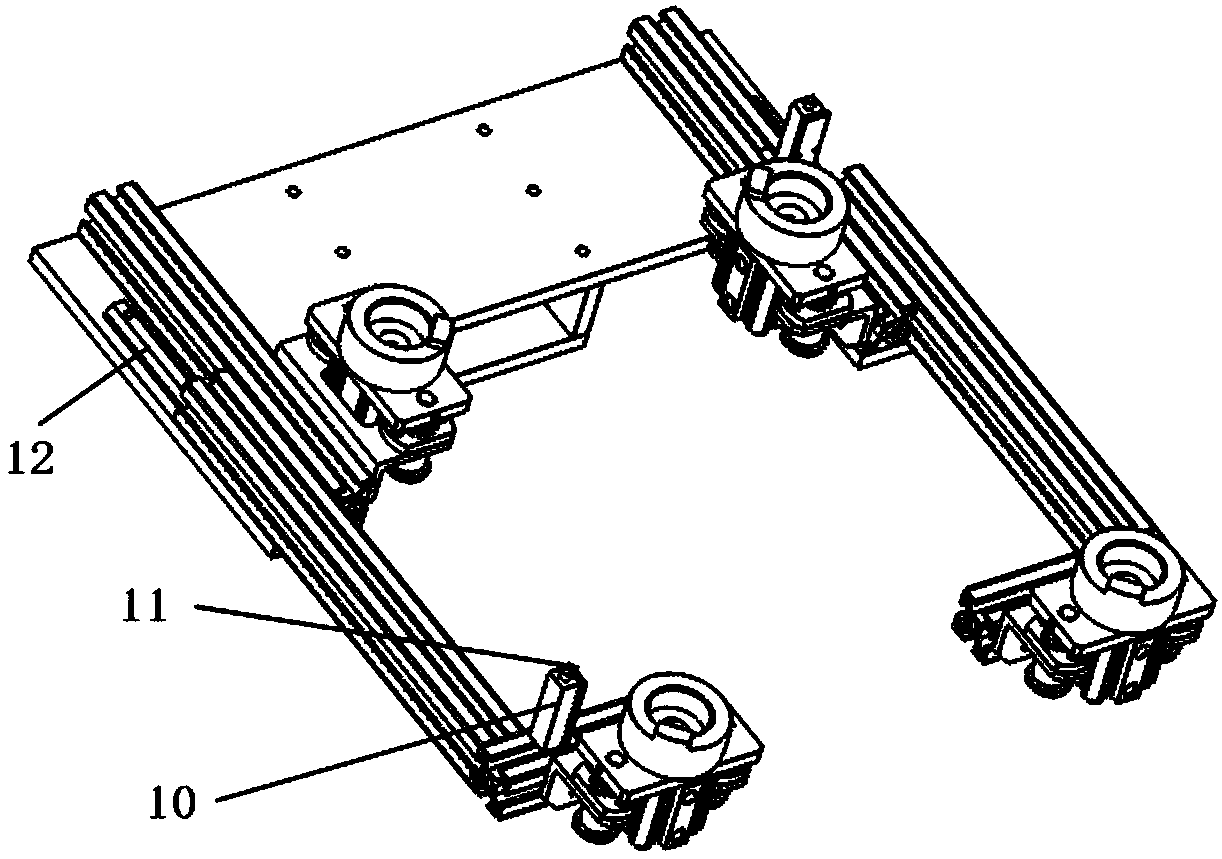

[0030] S2. Judging the positions of the shrinkable adsorption fixture bracket (6) and the second adsorption fixture bracket (7) and automatically shrinking to meet the size of the product.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com