Fully-automatic shunt winding process and equipment for gift wrapping paper

A wrapping paper, fully automatic technology, applied in the directions of transportation and packaging, winding strips, sending objects, etc., can solve the problem of the width of the slitting cannot be adjusted, and the dust removal operation cannot be performed, so as to achieve convenient slitting, smooth surface, change The effect of width size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

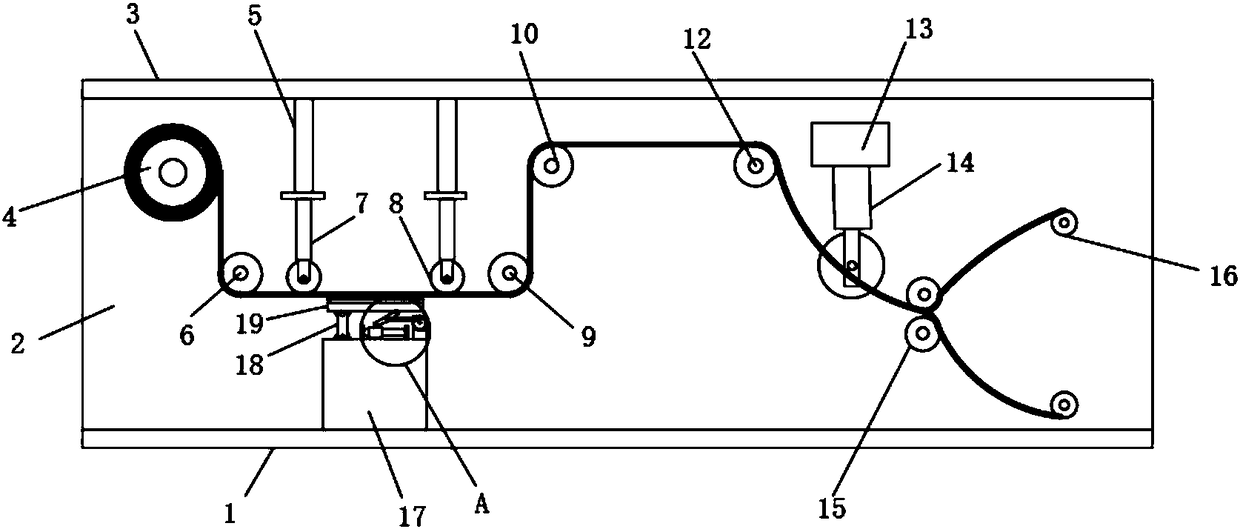

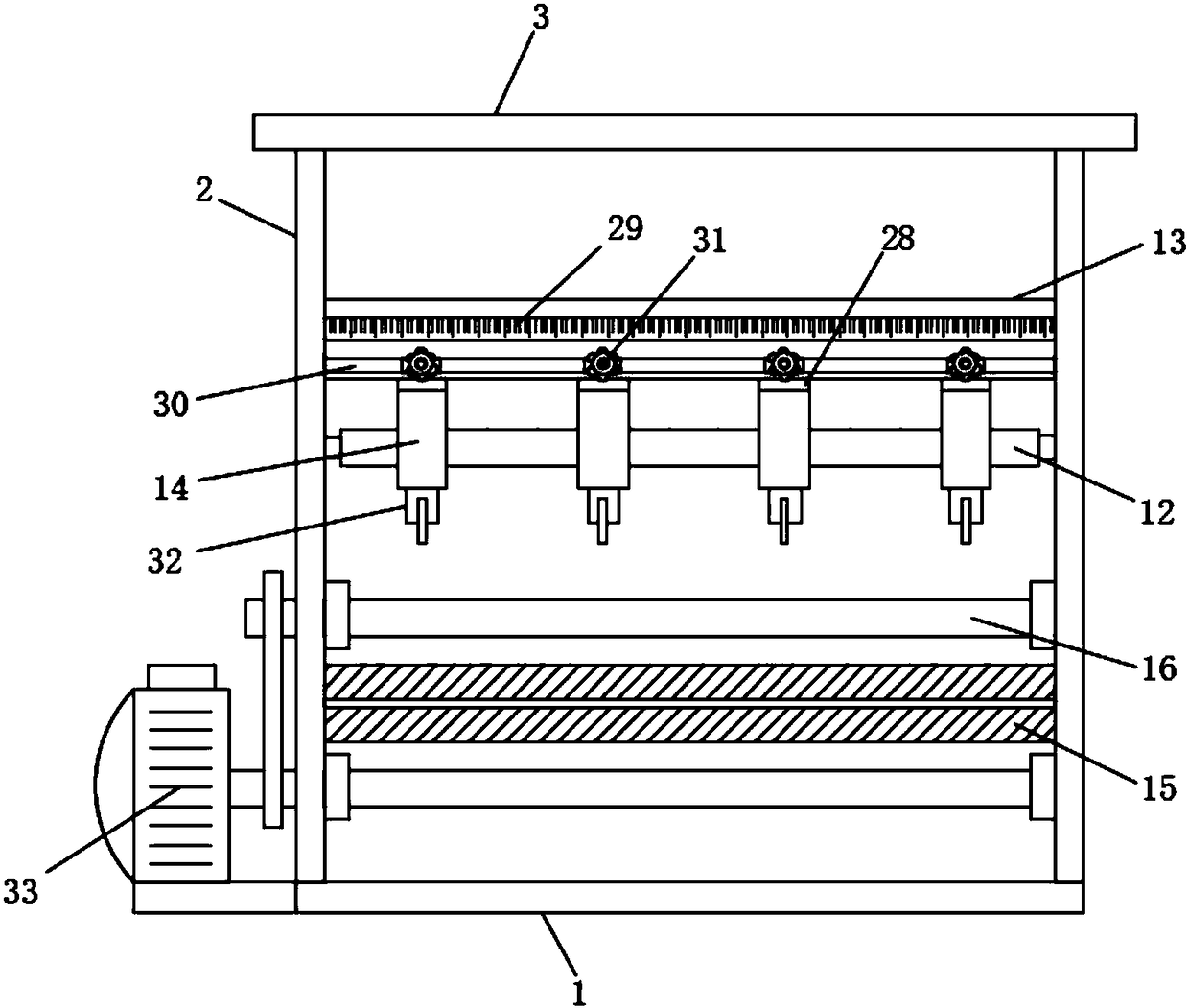

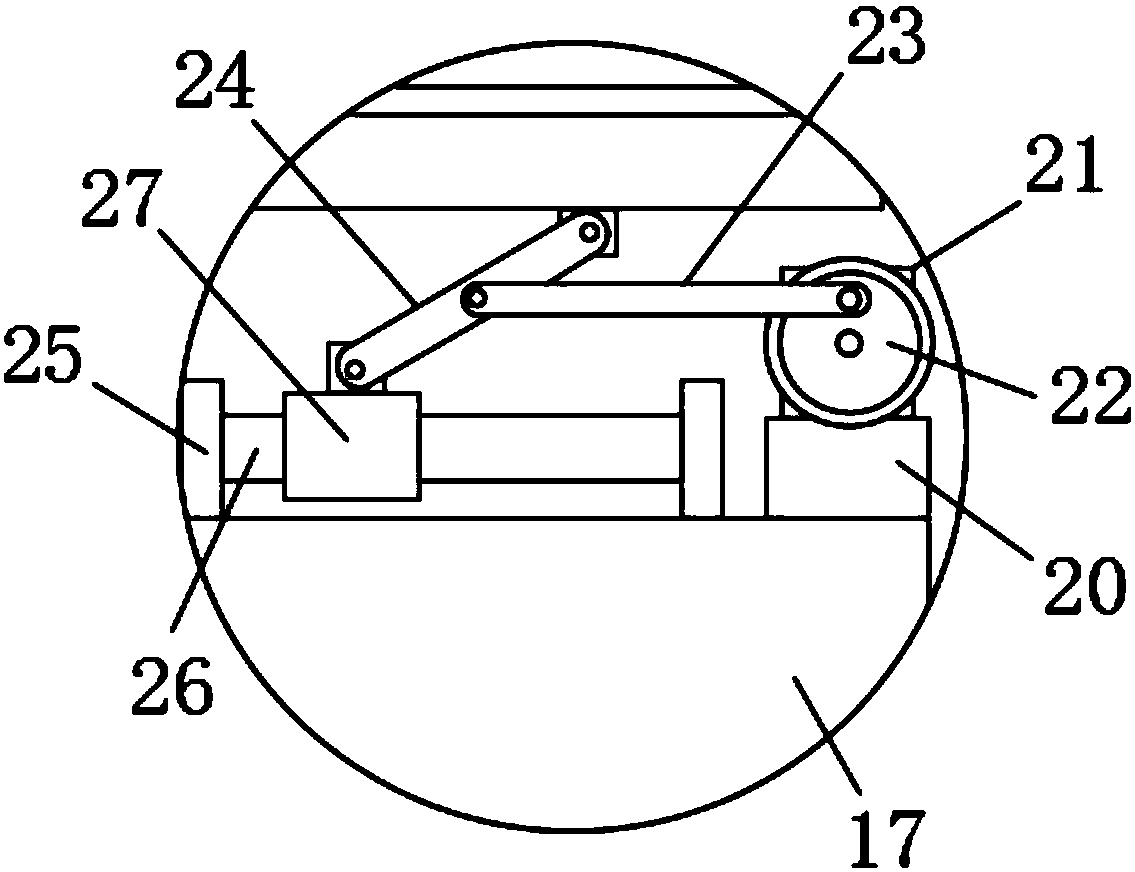

[0033] refer to Figure 1-5 , a kind of gift wrapping paper full-automatic rolling equipment, comprises base plate 1, the side plate 2 that is vertically arranged is fixed on both sides of the top of base plate 1, the top plate 3 that is fixed on the top of two side plates 2, two side plates 2 There are unwinding roller 4, first guide roller 6, second guide roller 9, third guide roller 10, fourth guide roller 12, adjusting rod 13, fifth guide roller 15 and winding roller 16 installed on one side of the room. The bottom of the top plate 3 between the first guide roller 6 and the second guide roller 9 is equipped with two pressing devices, and the top of the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com